Novel zinc-aluminum-magnesium alloy material and production method

A technology of aluminum-magnesium alloys and alloys, which is applied in the field of new zinc-aluminum-magnesium alloy materials and production, and can solve problems such as inferior binary alloy materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The data listed in Table 1, Table 2, Table 3, Table 4, and Table 5 below are examples only, and are not limiting. It is only for those skilled in the art to make options, and it can be adjusted adaptively.

[0036] Wherein, the rare earth RE is selected from Ce, La, Pr, and Nd elements, and the rare earth RE elements can be added in combination or alone.

[0037] In addition, although the trace metal elements Fe, Cu, Pb, and Cd in Table 2-5 are added separately, it is only an example. The trace metal elements Fe, Cu, Pb, and Cd can also be added in combination or individually.

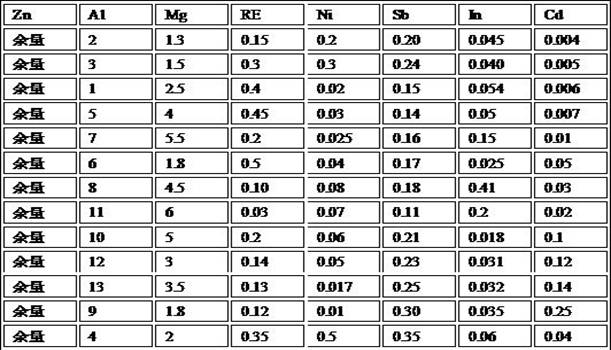

[0038] Table 1: The percentage of each component in the total amount (%)

[0039]

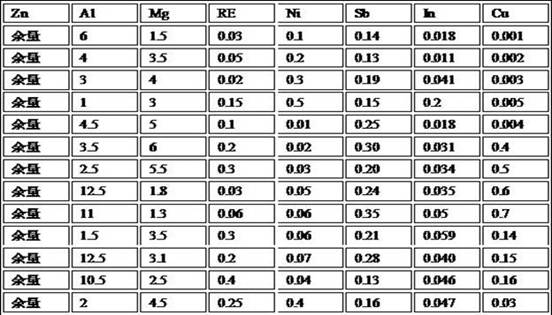

[0040] Table 2: The percentage of each component in the total amount (%)

[0041]

[0042] Table 3: The percentage of each component in the total amount (%)

[0043]

[0044] Table 4: The percentage of each component in the total amount (%)

[0045]

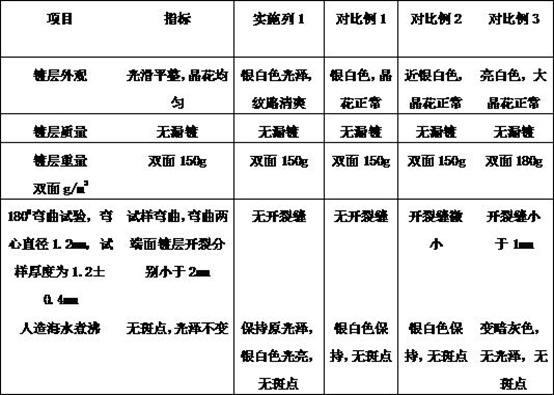

[0046] Table 5: The percentage of each compone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com