Preparation method of water-soluble humic acid fertilizer

A technology of water-soluble humic acid and humic acid, which is applied in the direction of alkaline orthophosphate fertilizer, nitrate fertilizer, ammonium orthophosphate fertilizer, etc., can solve the problems of affecting fertilizer efficiency and unsatisfactory effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

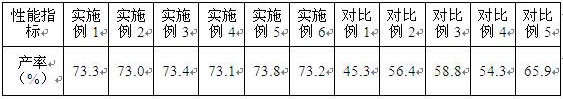

Examples

Embodiment 1

[0033] (1) Add mineral humic acid to the colloid mill for grinding, then add hydrogen peroxide solution, and then inject ozone from the bottom to oxidize mineral humic acid, set the colloid mill speed to 11000r / min, and the line speed to 28m / s, keep the pressure at 0.3MPa, and release to normal pressure after grinding for 4 hours, the obtained oxidized mineral source humic acid; the mineral source humic acid is weathered coal humic acid; the mass fraction of hydrogen peroxide solution is 36%;

[0034] The ratio of each raw material is, by weight, 46 parts by weight of mineral source humic acid, 3 parts by weight of hydrogen peroxide solution, and 0.05 parts by weight of ozone;

[0035] (2) Continue to add potassium hydroxide solution to the colloid mill of oxidized ore humic acid prepared in step (1), grind and activate, accelerate the dissolution of oxidized humic acid in alkali, set the colloid mill speed to 6800 r / min, The linear speed is 19m / s, and the grinding time at no...

Embodiment 2

[0044] (1) Add mineral humic acid to the colloid mill for grinding, then add hydrogen peroxide solution, and then inject ozone from the bottom to oxidize mineral humic acid. Set the colloid mill speed to 9000r / min and the line speed to 26m / s, keep the pressure at 0.25MPa, and release it to normal pressure after grinding for 4 hours to obtain the oxidized mineral source humic acid; the mineral source humic acid is peat humic acid; the mass fraction of hydrogen peroxide solution is 32%;

[0045] The ratio of each raw material is, in parts by weight, 48 parts by weight of mineral source humic acid, 3 parts by weight of hydrogen peroxide solution, and 0.05 parts by weight of ozone;

[0046] (2) Continue to add potassium hydroxide solution to the colloid mill of oxidized ore humic acid prepared in step (1), grind and activate, accelerate the dissolution of oxidized humic acid in alkali, set the colloid mill speed to 6500 r / min, The linear speed is 16m / s, and the grinding time at n...

Embodiment 3

[0055] (1) Add mineral humic acid to the colloid mill for grinding, then add hydrogen peroxide solution, and then inject ozone from the bottom to oxidize mineral humic acid. Set the colloid mill speed to 11000r / min and the line speed to 32m / s, keep the pressure at 0.4MPa, and release to normal pressure after grinding for 3h, the obtained oxidized mineral source humic acid; the mineral source humic acid is lignite humic acid; the mass fraction of hydrogen peroxide solution is 38%;

[0056] The ratio of each raw material is, in parts by weight, 42 parts by weight of mineral source humic acid, 4 parts by weight of hydrogen peroxide solution, and 0.06 parts by weight of ozone;

[0057] (2) Continue to add potassium hydroxide solution to the colloid mill of oxidized ore humic acid prepared in step (1), grind and activate, accelerate the dissolution of oxidized humic acid in alkali, set the colloid mill speed to 7500 r / min, The linear speed is 22m / s, and the grinding time at normal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com