Drilling wastewater treatment device and method

A technology for drilling wastewater and treatment devices, applied in mining wastewater treatment, water/sewage treatment, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to illustrate the present invention more clearly, the present invention will be further described below in conjunction with preferred embodiments. Those skilled in the art should understand that the content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention.

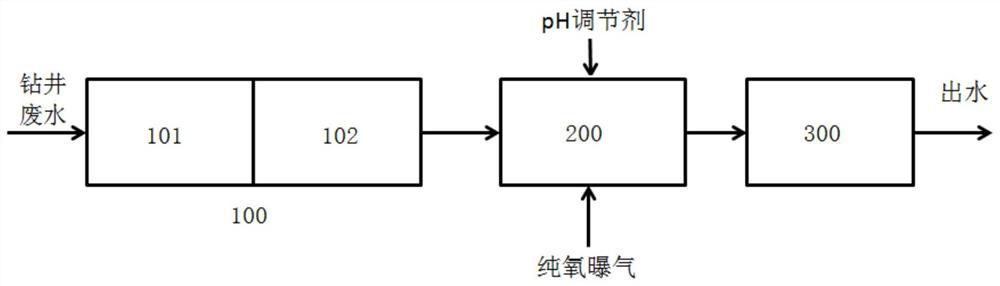

[0041] From August to October 2017, the combined process of the present invention was used to complete the application research on the reuse and treatment of drilling wastewater in an oil and gas development enterprise. The processing flow of the device is as follows figure 1 Shown:

[0042] 1. First, use the lifting device to lift the drilling wastewater to the electrocoagulation reaction tank 100. The electrodes are iron electrodes, and the inside of the tank body is set as an electrolysis reaction zone 101 and a flocculation sedimentation zone 102. Drilling waste water passes through the electrolysis reaction zone 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com