Improvement method of heavy loamy alkaline paddy soil

A paddy soil and soil technology, which is applied in the improvement field of heavy loamy alkaline paddy soil, can solve the problem of less research on texture structure improvement of heavy loamy alkalized paddy soil, and achieves elimination of pulping phenomenon, low production cost and high price. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

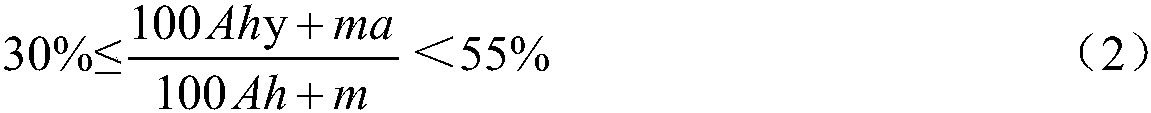

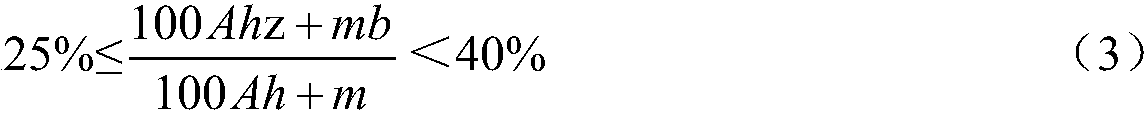

Method used

Image

Examples

Embodiment 1

[0030] Take soil samples from the plow layer (0-20cm) in the heavy loamy alkalized paddy soil area to be improved, and analyze the mechanical composition after air-drying (see Table 1), and the soil bulk density is 1.31g / cm 3 . Screen the iron tailings to retain physical sand particles (0.01mm≤particle size<1mm). Mix the physical sand particles of iron tailings with sulfuric acid solution with a mass concentration of 30% at a soil-water mass ratio of 1:5, let it stand for 48 hours, and air-dry it for later use. At this time, the pH of the acidified iron tailing mineral sand particles is measured to be 2.32 . Analyze the mechanical composition of iron tailing mineral rational sand before and after acidification, and determine the specific content of silt (0.01mm≤particle size<0.05mm) and sand (0.05mm≤particle size<1mm) in physical sand. For specific results, see Table 2 and Table 3.

[0031] Table 1 Mechanical composition of heavy loam alkalized paddy soil

[0032] ...

Embodiment 2

[0045] Take soil samples from the plow layer (0-20cm) in the heavy loam alkalized paddy soil area to be improved, the mechanical composition is shown in Table 6, and the soil bulk density is 1.31g / cm 3 . Screen the iron tailings to retain physical sand particles (0.01mm≤particle size<1mm). Mix the physical sand of the iron tailings with the sulfuric acid solution with a mass concentration of 30% according to the mass soil-water ratio of 1:5, let it stand for 48 hours, and air-dry it for later use. At this time, the pH of the acidified iron tailing mineral sand is 2.28 . See Table 2 and Table 7 for the mechanical composition of iron tail mineral rational sand grains before and after acidification.

[0046] Table 6 Mechanical composition of heavy loam alkalized paddy soil

[0047] Particle size classification 0.01≤~ 0.05≤~ content(%) 31.1 40.5 28.4

[0048] Table 7 Mechanical composition of acidified iron tail mineral rational sand grains

[0049...

Embodiment 3

[0057] Take soil samples from the plow layer (0-20cm) in the heavy loam alkalized paddy soil area to be improved, the mechanical composition is shown in Table 10, and the soil bulk density is 1.31g / cm 3 . Screen the iron tailings to retain physical sand particles (0.01mm≤particle size<1mm). Mix the physical sand particles of iron tailings with the hydrolyzed polymaleic anhydride solution with a solid content of 48% at a soil-water mass ratio of 1:5, let it stand for 48 hours, and air-dry it for later use. At this time, the mineral physical sand particles of acidified iron tailings The pH is 2.23. The mechanical composition of iron tail mineral rational sand grains before and after acidification is the same as Table 2 and Table 11.

[0058] Table 10 Mechanical composition of heavy loam alkalized paddy soil

[0059] Particle size classification 0.01≤~ 0.05≤~ content(%) 31.0 40.6 28.4

[0060] Table 11 Mechanical composition of acidified iron tail ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com