Mine water defluorination and boiler room desulfurization comprehensive treatment method

A comprehensive treatment, mine water technology, applied in mining wastewater treatment, adsorbed water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of unresolved defluorination and desulfurization drugs, such as no reuse and waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

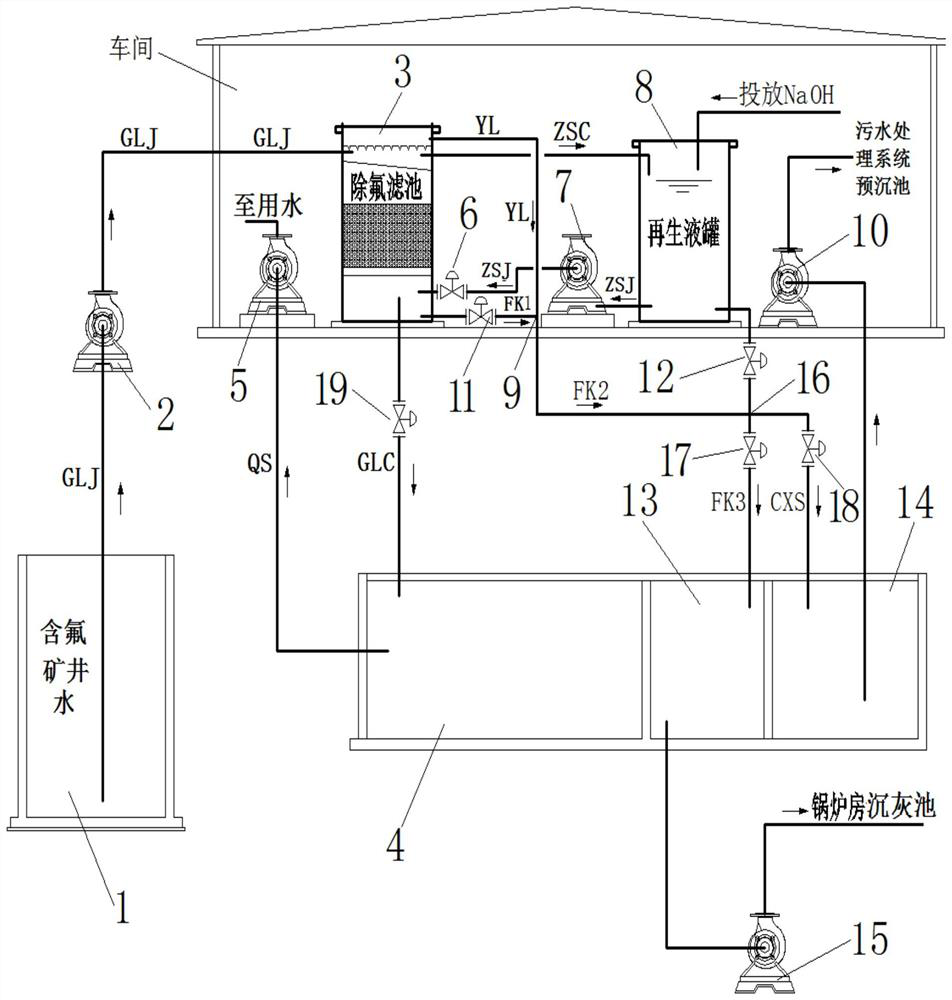

[0034] like figure 1 As shown, the comprehensive treatment system for mine water defluorination and boiler room desulfurization includes regulating tank 1, water inlet lifting pump 2, fluoride removal filter 3, clear water tank 4, domestic water lifting pump 5, filter regeneration inlet valve 6, Filter regeneration inlet pump 7, regeneration liquid tank 8, tee joint 9, intermediate pool lift pump 10, fluorine removal filter vent valve 11, regeneration liquid tank vent valve 12, waste liquid pool 13, intermediate pool 14, boiler room inlet Liquid pump 15, four-way joint 16, first control valve 17, second control valve 18, third control valve 19; defluoridation filter inlet pipe GLJ, defluoride filter water production pipeline GLC, filter regeneration inlet water Pipeline ZSJ, overflow pipe YL, regeneration liquid outlet pipe ZSC, first venting pipe FK1, second venting pipe FK2, third venting pipe FK3, defluoridation filter flushing water pipe CXS.

[0035] The regulating tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com