Treatment method of wastewater of oxalic acid production

A technology for the production of wastewater and treatment methods, which is applied in natural water treatment, water/sludge/sewage treatment, ion-exchange water/sewage treatment, etc. It can solve the problems of high energy consumption, environmental pollution, and high cost, and achieve low energy consumption , less equipment investment, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

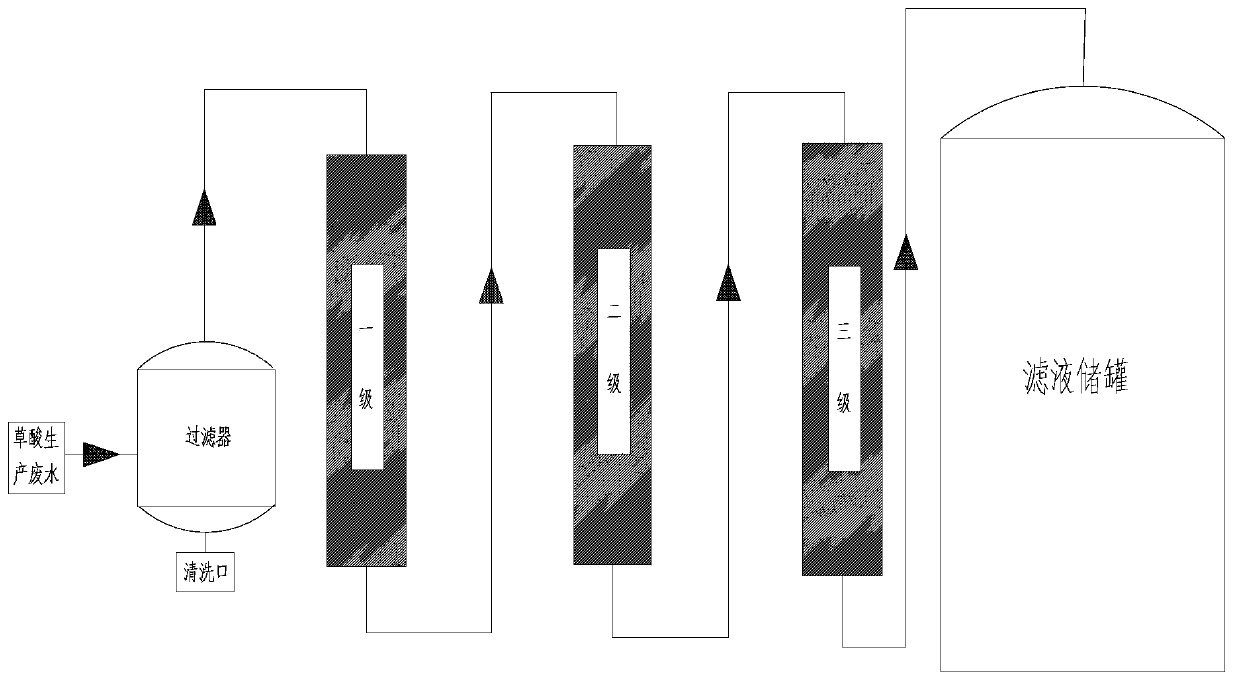

Image

Examples

Embodiment 1

[0030] Add 360ml of oxalic acid production wastewater that has been preliminarily filtered in a 500ml beaker for use. Inject organic macroporous adsorption resin into the chromatography column (to prevent air bubbles), and install 3 columns in total, each column is filled with 60ml macroporous adsorption resin, and soaked in water. Then arrange them in order of height, and place the beaker containing oxalic acid production wastewater at the highest position, so that a potential difference is formed between them. Use a rubber tube to connect the oxalic acid production wastewater and the chromatographic column in series, and drive away part of the air. Start to open the valves of each chromatographic column from high to low in turn, the first thing to flow out is clean water, use the siphon to suck the oxalic acid production wastewater in the beaker into the chromatographic column, and the adsorption and removal of impurities begins.

[0031]Adjust the outlet valve of the chrom...

Embodiment 2

[0033] Add 300ml of oxalic acid production wastewater that has been preliminarily filtered in a 500ml beaker for use. Inject organic macroporous adsorption resin into the chromatographic column (to prevent air bubbles), a total of 3 columns are packed, each column is filled with 50ml macroporous adsorption resin, and soaked in water. Then arrange them in order of height, and place the beaker containing oxalic acid production wastewater at the highest position, so that a potential difference is formed between them. Use a rubber tube to connect the oxalic acid production wastewater and the chromatographic column in series, and drive away part of the air. Start to open the valves of each chromatographic column from high to low in turn, the first thing to flow out is clean water, use the siphon to suck the oxalic acid production wastewater in the beaker into the chromatographic column, and the adsorption and removal of impurities begins.

[0034] Adjust the chromatographic column...

Embodiment 3

[0036] Add 300ml of oxalic acid production wastewater that has been preliminarily filtered in a 500ml beaker for use. Inject organic macroporous adsorption resin into the chromatographic column (to prevent air bubbles), a total of 3 columns are packed, each column is filled with 50ml macroporous adsorption resin, and soaked in water. Then arrange them in order of height, and place the beaker containing oxalic acid production wastewater at the highest position, so that a potential difference is formed between them. Use a rubber tube to connect the oxalic acid production wastewater and the chromatographic column in series, and drive away part of the air. Start to open the valves of each chromatographic column from high to low in turn, the first thing to flow out is clean water, use the siphon to suck the oxalic acid production wastewater in the beaker into the chromatographic column, and the adsorption and removal of impurities begins.

[0037] Adjust the chromatographic column...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com