Connecting structure of round metal part and fiber reinforced composite material

A connection structure and fiber-reinforced technology, which is applied in the field of connection methods of different components, can solve the problems of large difference in thermal expansion coefficient between metals and easy interface peeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, the present invention will be further described:

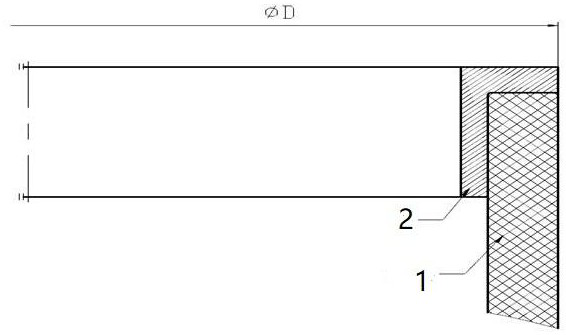

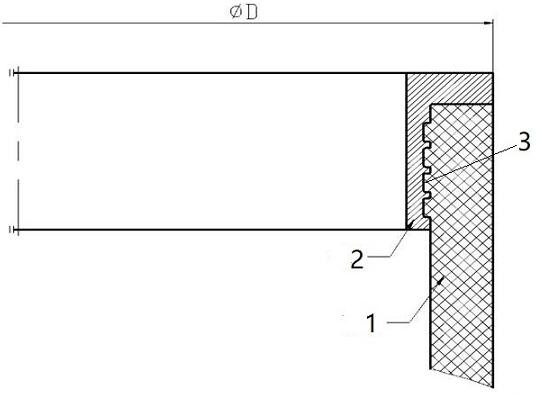

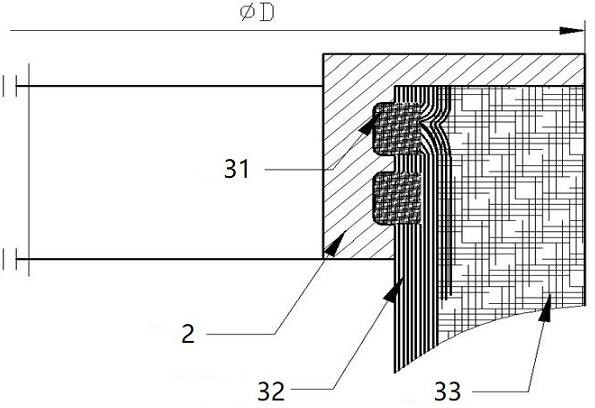

[0022] as above figure 2 , image 3 , the interface between the circular metal part and the composite material has the following gain design:

[0023] 1) Add a certain number of grooves 3 on the contact surface between the circular metal part 2 and the circular composite material 1, on the one hand to increase the bonding area, and on the other hand to embed and connect the composite material;

[0024] 2) The bonding interface is changed from a smooth surface to a rough surface, which greatly increases the bonding area and improves the bonding strength;

[0025] 3) When laying the fiber in the groove, the fiber filaments are wound in the groove 3 and diverged into an umbrella shape, the schematic diagram is as follows image 3 As shown, the divergent fiber filaments 32 and the fiber cloth 33 are laid alternately, and then vacuum forming is used to connect the fiber fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com