Movable steel rail shearing machine and application method

A shearing machine, mobile technology, applied in the direction of shearing device, shearing machine equipment, accessories of shearing machine, etc., can solve the problems of unguaranteed safety and environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

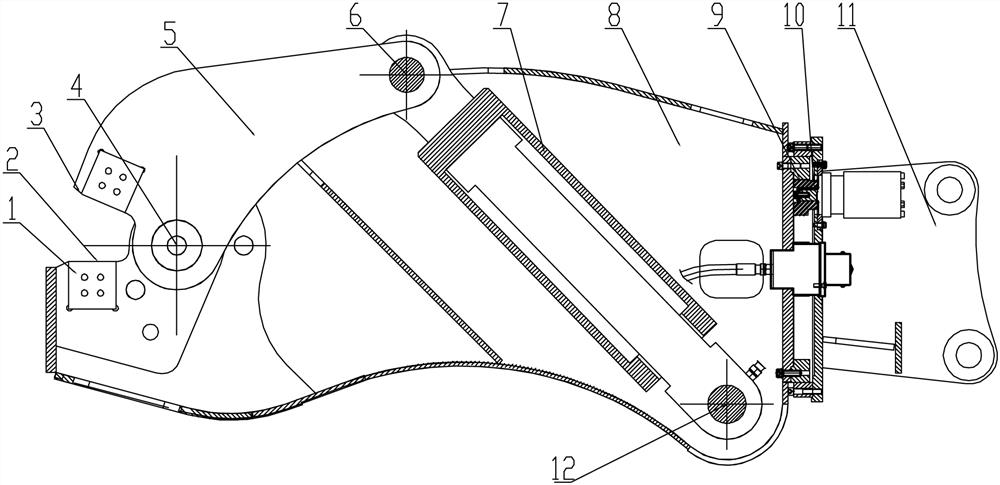

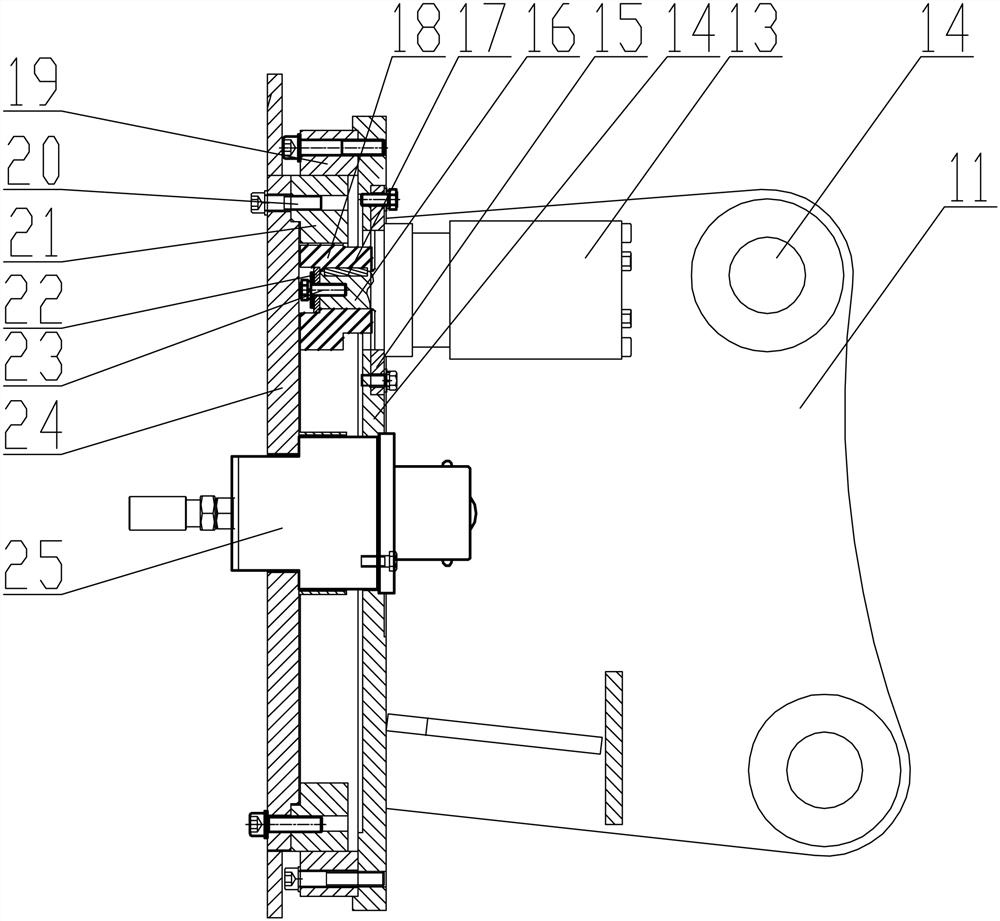

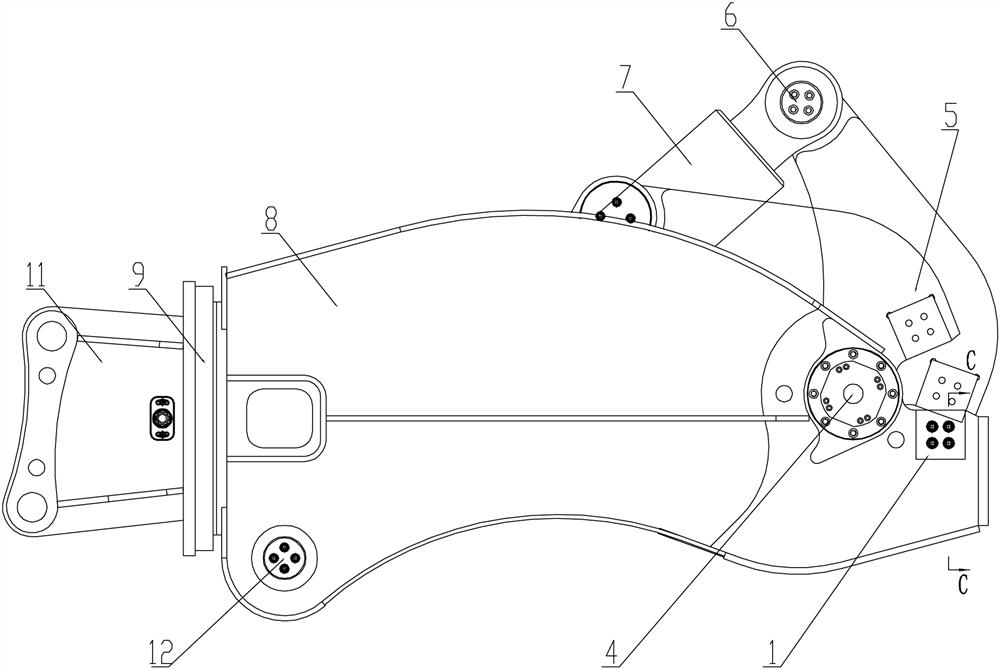

Embodiment 1

[0038] see Figure 1-6 , a mobile rail shearing machine, which includes a knife body connecting seat 11, a rotating disc 24 is installed on the outer wall of the knife body connecting seat 11 through a rotary drive mechanism 9, and a fixed knife is fixedly installed on the outer end surface of the rotating disc 24 body 8, the head of the fixed cutter body 8 is hinged with a movable cutter body 5 through the kingpin shaft system 4, and a shearing power device is arranged between the movable cutter body 5 and the fixed cutter body 8; the fixed cutter body 8 and the head of the moving knife body 5 are respectively processed with a first cutout 2 and a second cutout 3, and the first cutout 2 and the second cutout 3 are respectively equipped with a shear blade 1 . By adopting the above structure, the rail shearing machine can be used for shearing rails. In the specific use process, the above-mentioned movable knife body 5 is driven by a shearing power device, and then through the...

Embodiment 2

[0054] The method of using the mobile rail shearing machine for rail shearing comprises the following steps:

[0055] Step 1: Fix the shearing machine to the end of the mechanical arm of the mobile device through the knife body connecting seat 11;

[0056] Step 2: Use mobile equipment to move to the location of the rail;

[0057] Step 3: Operate the mechanical arm to open the fixed knife body 8 and the movable knife body 5 of the shearing machine, and make the position of the knife edge clamp the rail;

[0058] Step 4: Start the shearing power device, drive the movable cutter body 5 through the shearing oil cylinder 7 of the shearing power device, and cut the rail through the cooperation between the movable cutter body 5 and the fixed cutter body 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com