Ladle blowing argon upper nozzle seat brick and preparation method thereof

A technology for nozzle block and ladle, which is applied to manufacturing tools, casting equipment, metal processing equipment, etc., can solve the problems of affecting service life, mismatch of furnace and machine, foreign matter of castables affecting air permeability, etc., and achieve the effect of prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

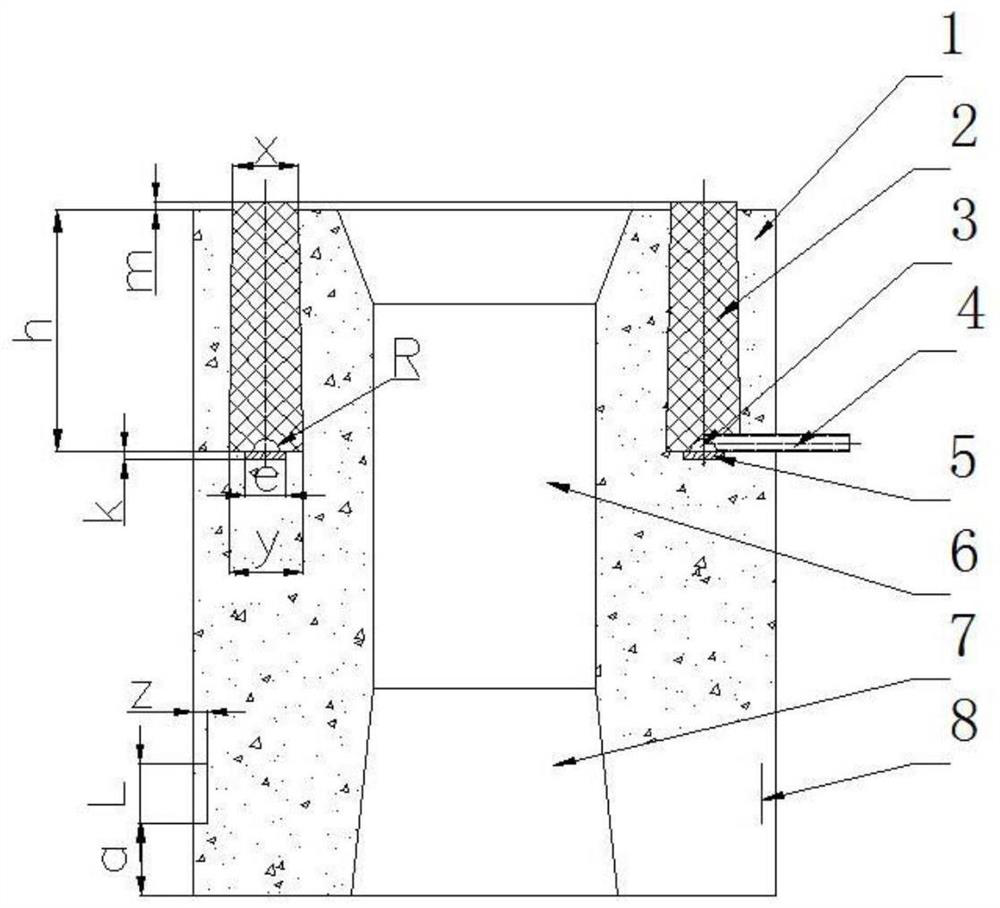

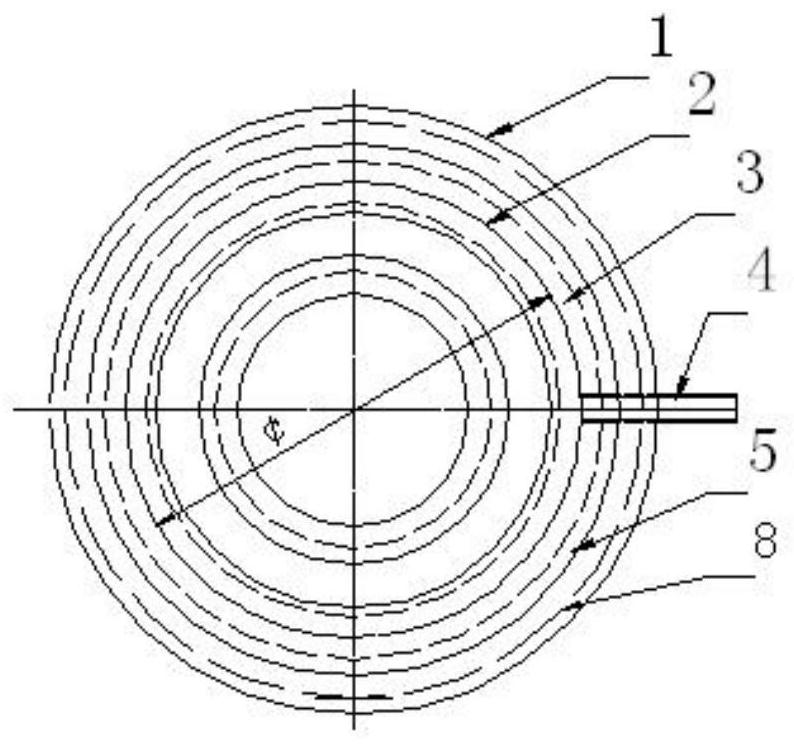

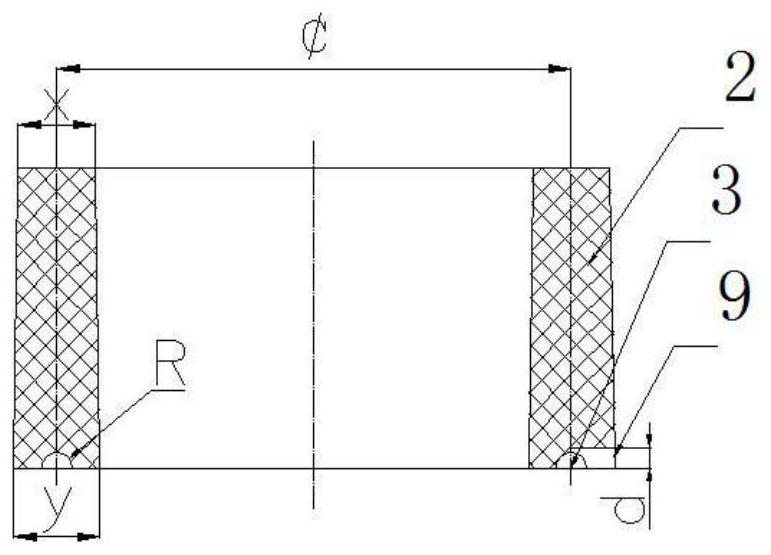

[0040] A ladle blowing argon upper nozzle block, such as Figure 1-Figure 6 As shown, it includes ladle argon-blowing upper nozzle block body 1, diffused breathable ring 2, air chamber 3, air intake pipe 4, air chamber cover plate 5, iron ring 8, and the middle part of ladle argon-blown upper nozzle block body 1 There are steel flow holes 6 and upper nozzle installation holes 7 that penetrate up and down. The body 1 of the ladle blowing argon upper nozzle block body 1 is provided with a diffused breathable ring 2, an air chamber 3 and an air chamber cover 5 from top to bottom. The upper end of the air-permeable ring protrudes from the upper surface of the ladle blowing argon upper nozzle block. The air chamber 3 is formed on the bottom of the diffuse air-permeable ring. The lower mouth of the air chamber 3 is provided with an air chamber cover plate 5. The air chamber cover plate 5 communicates with the air chamber 3, and the other end protrudes from the side of the ladle blow...

Embodiment 2

[0057] Ladle blowing argon upper nozzle seat brick as described in Example 1, the difference is:

[0058] The diffused air-permeable ring 2 is circular as a whole, and its longitudinal section is isosceles trapezoidal. The upper width x of the ring is 40mm, the lower width y is 45mm, and the height h is 160mm.

[0059] The air chamber 3 has a circular shape as a whole, the longitudinal section of the air chamber is semicircular, and its radius R is 10 mm.

[0060] The air chamber cover plate 5 is circular as a whole, and its longitudinal section is rectangular. The ring width e of the air chamber cover plate 5 is greater than the diameter 2R (20mm) of the air chamber 3, but smaller than the lower width y (45mm) of the air-permeable ring 2 ), e is 32mm.

[0061] The iron ring 8 is circular as a whole, the height L is 50 mm, the distance a between the lower end of the iron ring and the lower end of the ladle argon-blowing upper nozzle block body 1 is 60 mm, and the iron ring 8 ...

Embodiment 3

[0069] Ladle blowing argon upper nozzle seat brick as described in Example 1, the difference is:

[0070] The upper width x of the diffused air-permeable ring 2 is 30 mm, the lower width y is 40 mm, and the height h is 100 mm. The radius R of the longitudinal section of the gas chamber 3 is 8 mm.

[0071] The air chamber cover plate 5 is circular as a whole, and its longitudinal section is rectangular. The ring width e of the air chamber cover plate 5 is greater than the diameter 2R (16mm) of the air chamber 3, but smaller than the lower width y (40mm) of the air-permeable ring 2 ), e is 30mm.

[0072] The iron ring 8 is circular as a whole, the height L is 45mm, the distance a between the lower end of the iron ring and the lower end of the ladle argon-blowing upper nozzle block body 1 is 55mm, and the iron ring 8 is buried in the steel ladle argon-blown upper nozzle block body The inner depth z of the surface layer is 15mm.

[0073] The height m that the upper end of the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com