Metal atmospheric corrosion monitoring sensor

A technology for monitoring sensors and atmospheric corrosion, applied in the field of sensors, can solve problems such as high manufacturing process requirements, structural shape affecting service life, high price, etc., to improve adhesion and ductility, slow down corrosion consumption process, and increase corrosion current Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

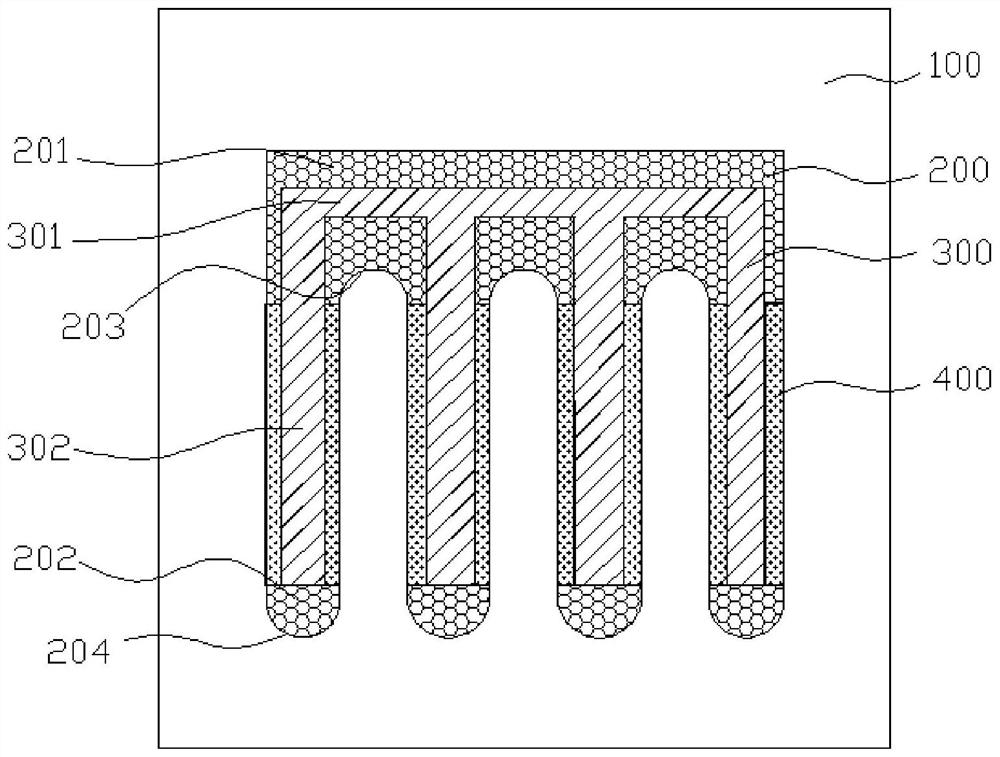

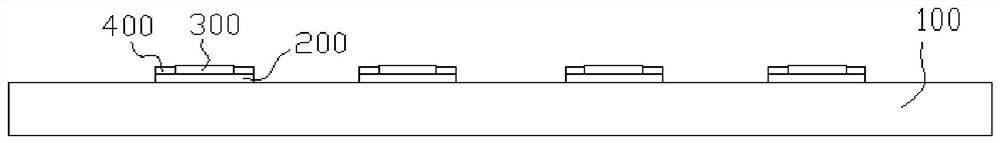

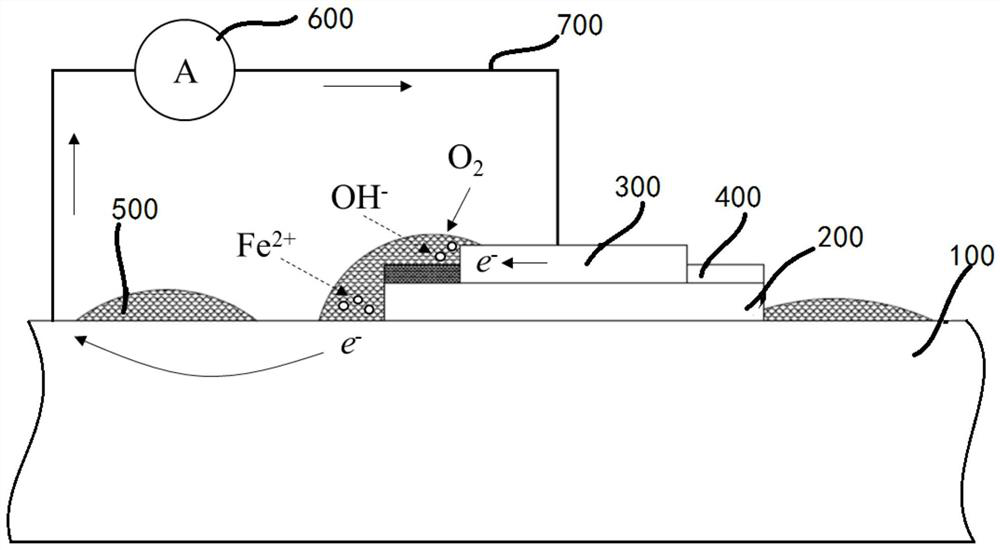

[0023] see figure 1 and figure 2 , a structural schematic diagram and a cross-sectional view of a specific embodiment of the metal atmospheric corrosion monitoring sensor of the present application, the metal atmospheric corrosion monitoring sensor includes a metal substrate 100, a hydrophobic insulating plate 200, a conductive material layer and a hydrophilic coating 400; the metal substrate The material 100 is a metal material to be tested, and the metal substrate 100 to be tested is a metal or alloy material with a smooth surface and no corrosion, such as iron, aluminum, copper, zinc, galvanized steel, and the like. The conductive material layer is a gold-plated layer 300 . The hydrophobic insulating board can be selected from epoxy resin board, silicone rubber board, Teflon board, etc., and the hydrophilic coating can be selected from organic glue containing polar groups.

[0024] The hydrophobic insulating plate 200 is bonded to the metal substrate 100, and the area of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com