Assembled pressurized tower crane foundation structure

A tower crane foundation and heavy-duty technology, applied in the direction of basic structure engineering, construction, etc., can solve the problems of weak anti-slip ability, difficult construction, difficult disassembly and assembly, etc., achieve strong torsion and shear resistance, and improve anti-skid Easy to move, disassemble and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

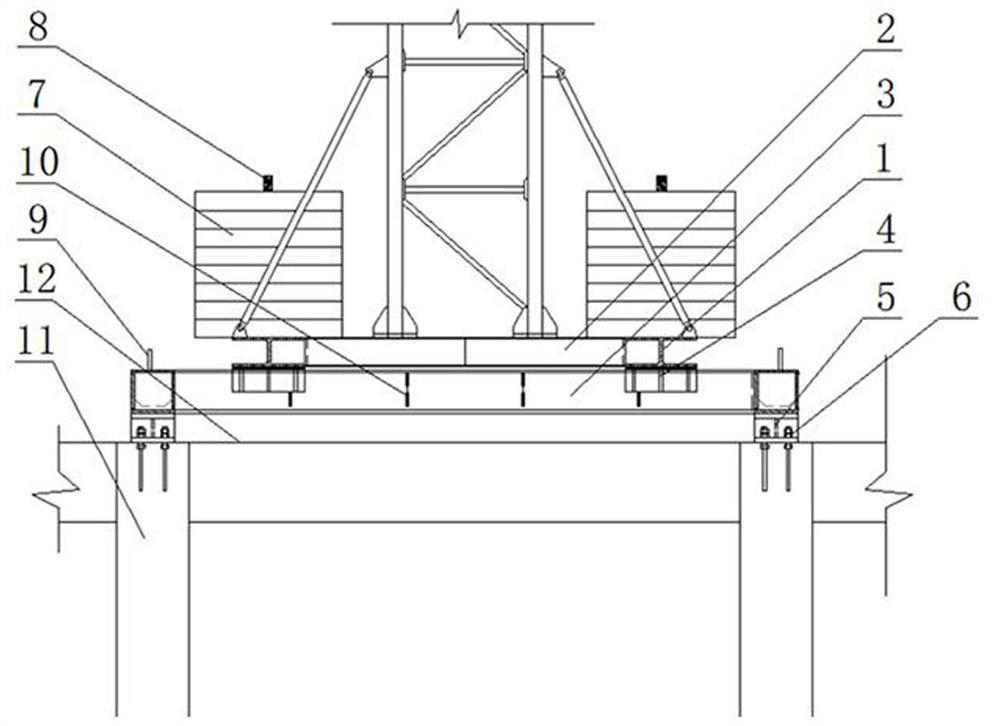

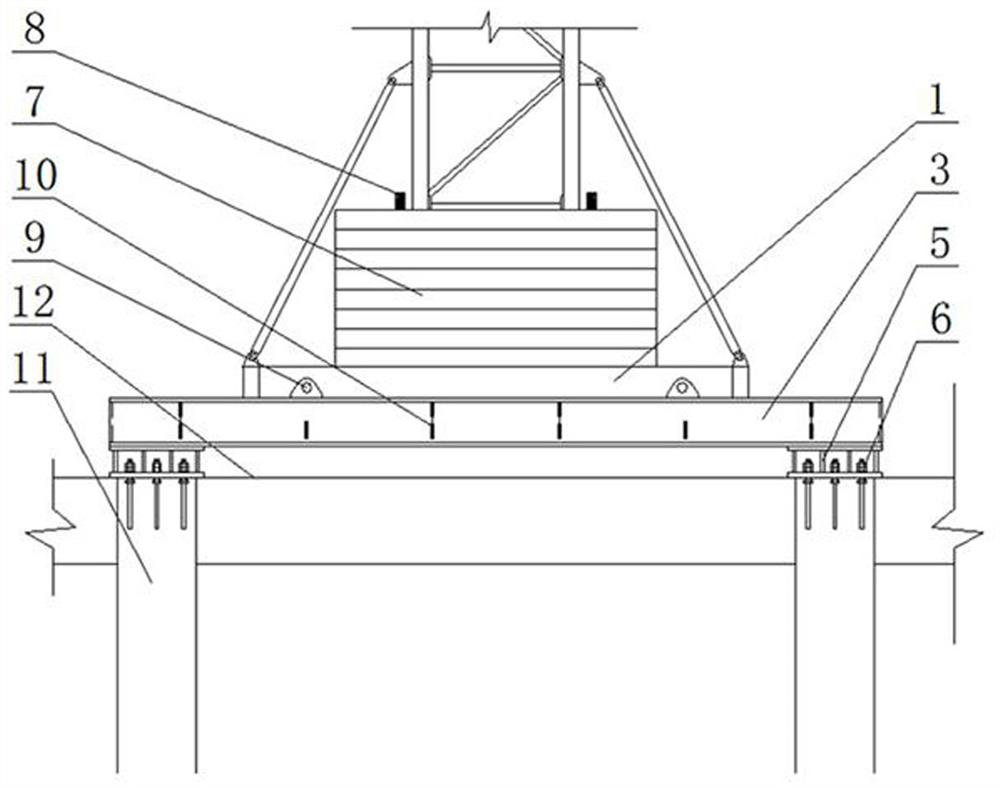

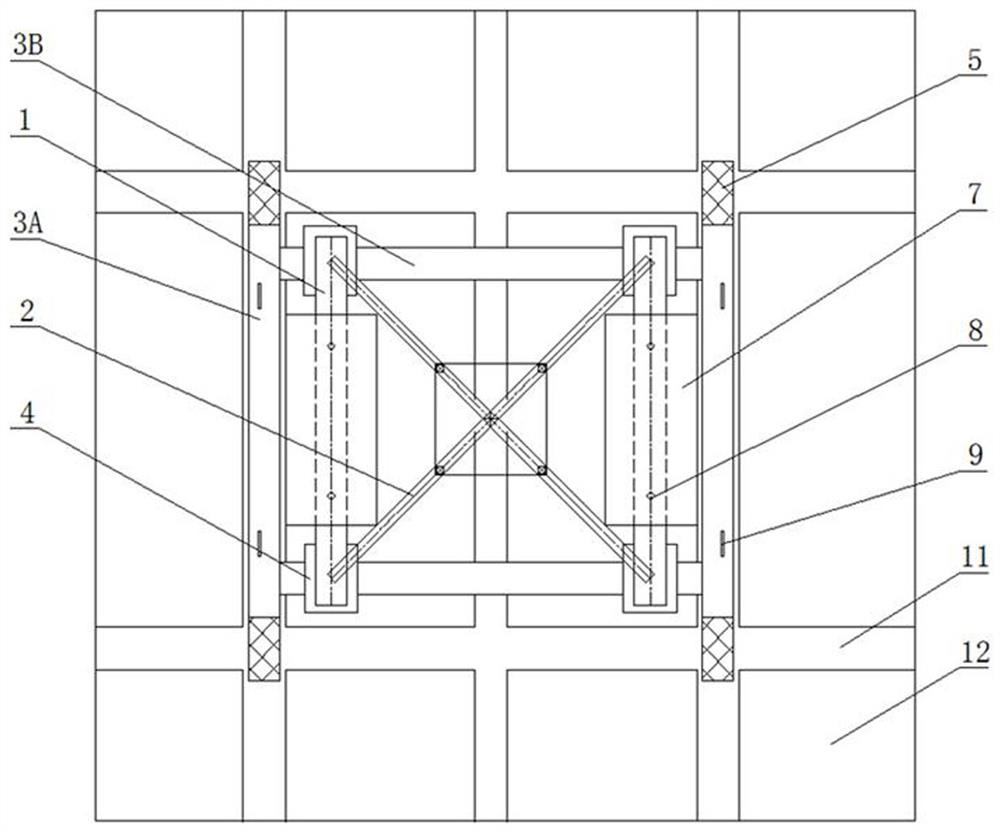

[0019] Such as Figures 1 to 5 As mentioned above, the present invention includes a tower crane base 1, a cross steel beam 2, a stressed steel box girder 3, a bolt 6, and a weight block 7. The stressed steel box girder 3 is a rectangular rigid structure, and the stressed steel box girder The bottom of 3 is fixedly connected with basement frame column structure 11 by bolts 6, the four ends of the cross steel beam 2 are respectively placed on the stressed steel box girder 3, and the tower crane base 1 is placed on both sides of the cross steel beam 2 On the stressed steel box girder 3, the weight bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com