Positioning tool for punching

A technology for positioning tooling and positioning grooves, applied in the field of machining, can solve the problems of inability to process horizontal stamping of workpieces, difficult end faces of rods, affecting the completion quality of stamping devices, etc., to achieve the effect of guaranteeing processing dimensions and avoiding springback

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

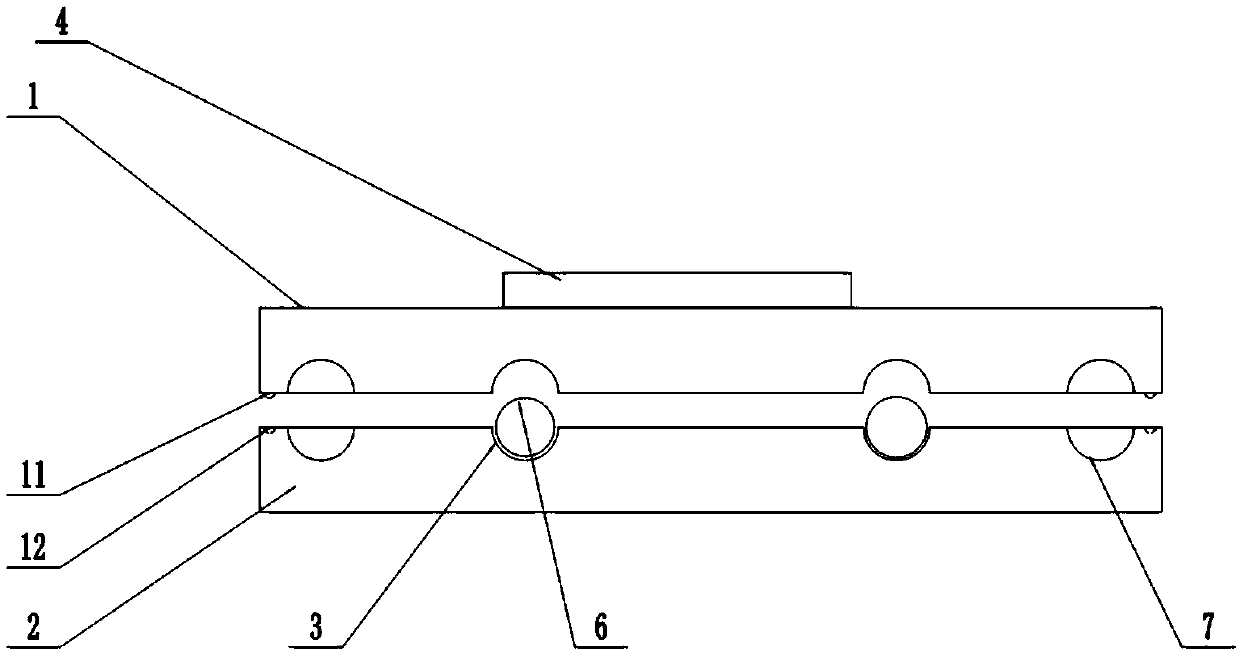

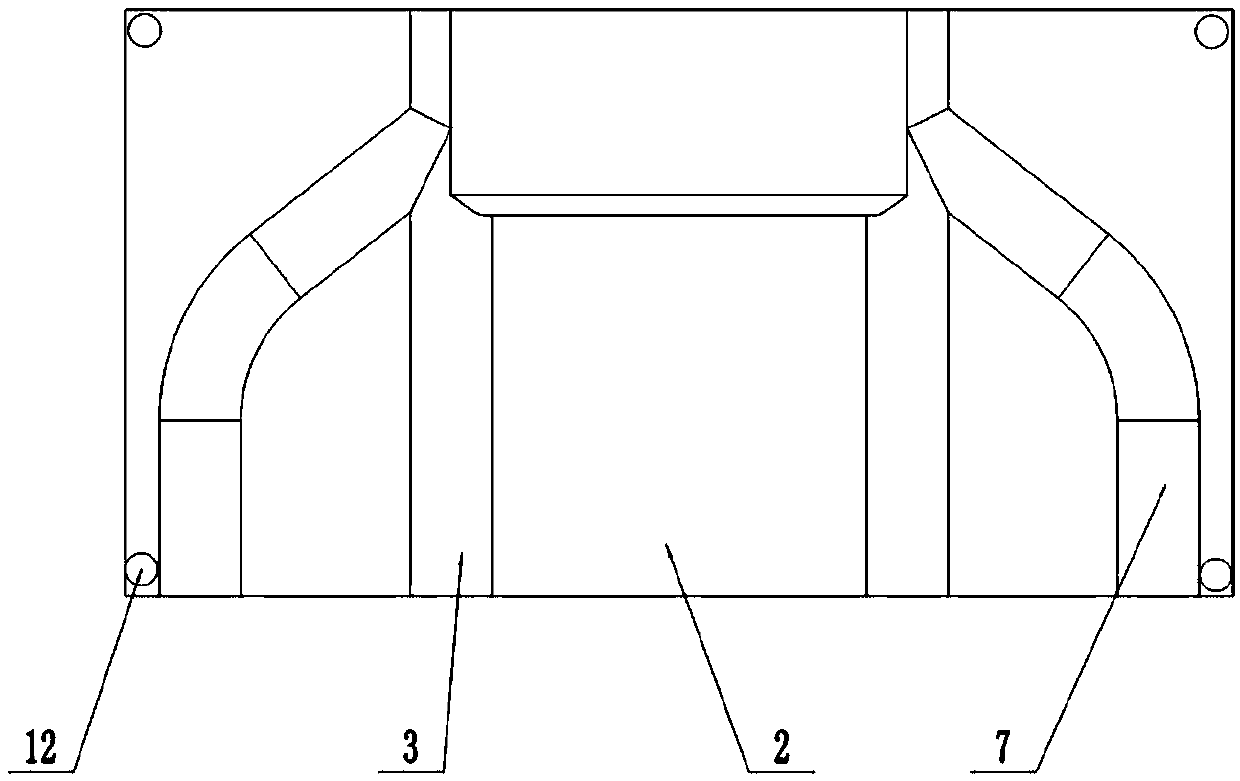

[0022] Embodiment 1 is basically as attached figure 1 and figure 2 Shown:

[0023] The orientation words such as "left, right" described in this embodiment are only limited to the appended figure 1 and figure 2 , a positioning tool for stamping, such as figure 1 As shown, the upper mold 1 and the lower mold 2 are included, and the power device for driving the upper mold 1 to move up and down is selected as the cylinder 5 in this embodiment, and the upper mold 1 and the lower mold 2 are equipped with a semicircular processing groove 7 in section. And chute 3, when the upper mold 1 and the lower mold 2 are engaged, the combination of the processing groove 7 and the cross section of the chute 3 is circular; as figure 2 As shown, the processing groove 7 intersects with the chute 3 at a certain angle, and the processing groove 7 is used to place and fix the workpiece. The chute 3 and the processing groove 7 are arranged symmetrically on both sides; the bolt at the end of th...

Embodiment 2

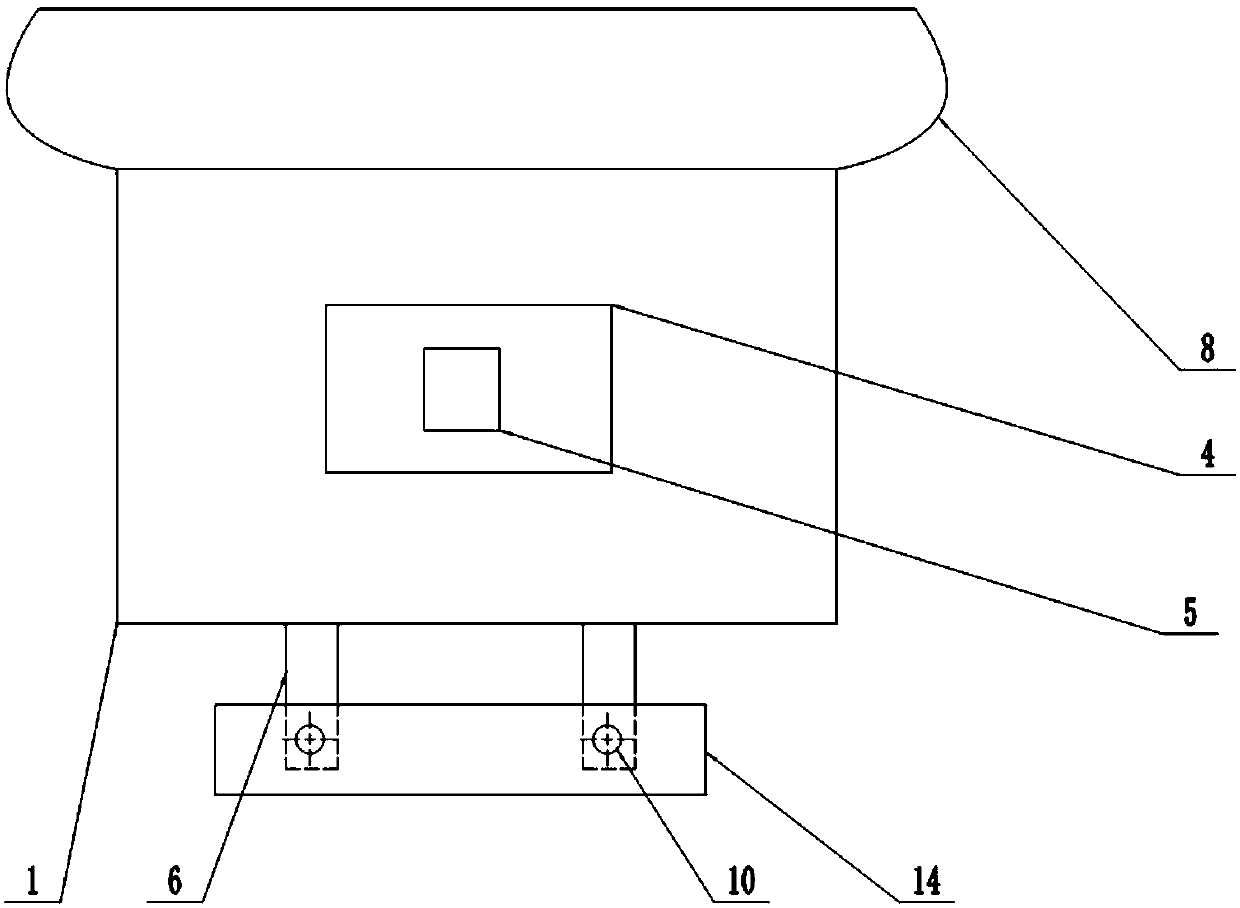

[0028] This embodiment increases the following on the basis of embodiment 1: as Figure 4 As shown, there is an air outlet pipe 9 connected to the cylinder 5, and the cylinder 5 drives the upper mold 1 to move upward and separate from the lower mold 2. During the separation process, the gas in the cylinder 5 is directed at the lower mold 2 through the air outlet of the air outlet pipe 9 for blowing treatment. like Figure 4 As shown, the lower die 2 is placed with a collection bag 8 in the downwind direction of the air flow; the gas can not only cool down the connecting rods that have just been stamped, facilitate the quick removal of the stamped connecting rods, but also accumulate the stamping process on the upper part of the lower die 2 Metal scraps are collected for disposal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com