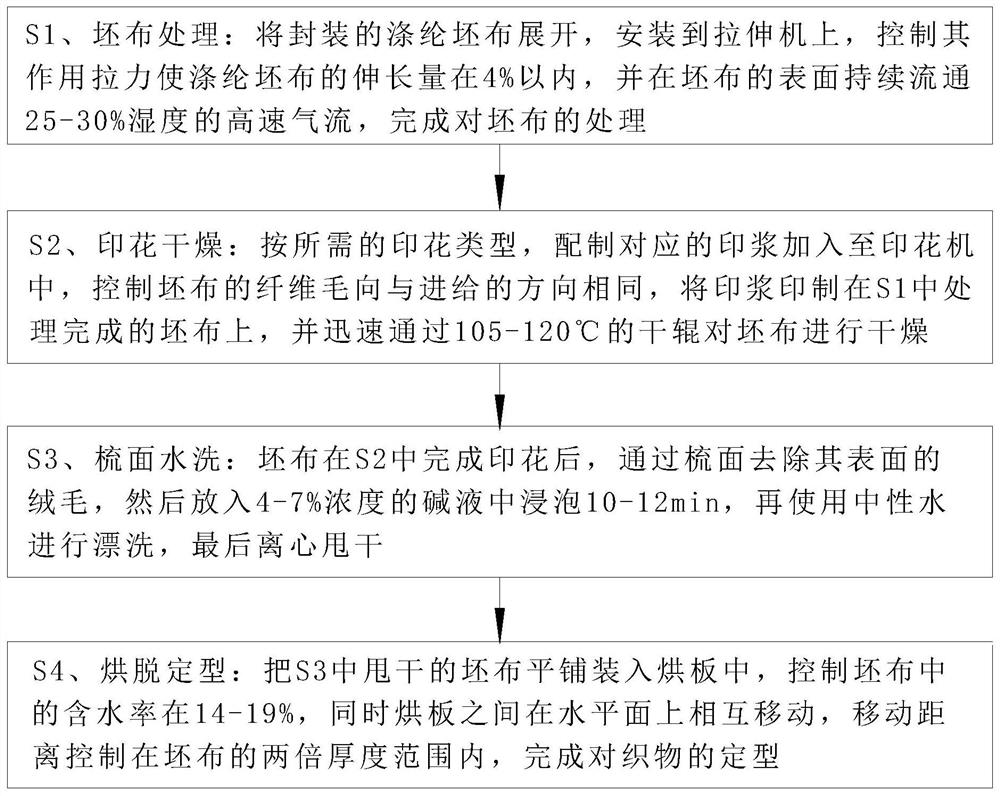

Polyester printed fabric thickened hand feeling process

A printing and polyester technology, applied in the direction of fabric elongation, fabric surface trimming, textile material treatment, etc., can solve the problems of weakening gray fabric processing, printing and printing effects, fiber structure damage, unresolved internal stress, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

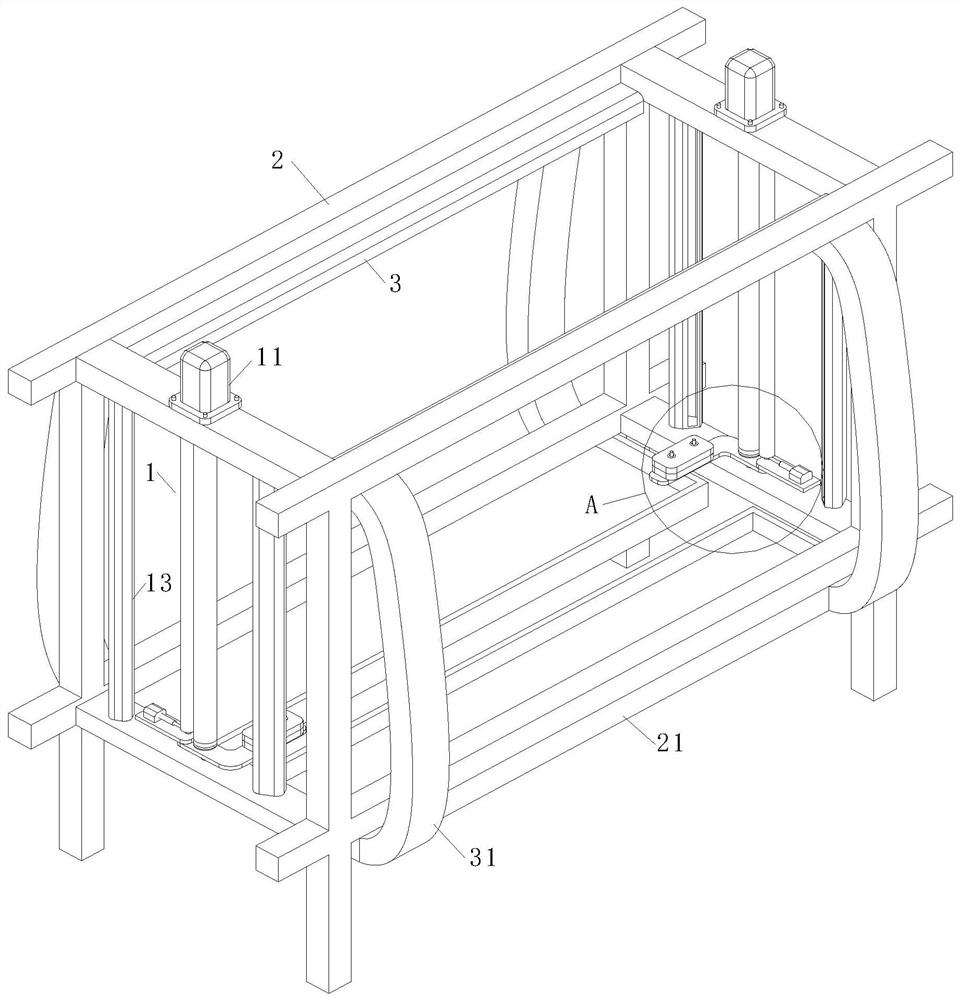

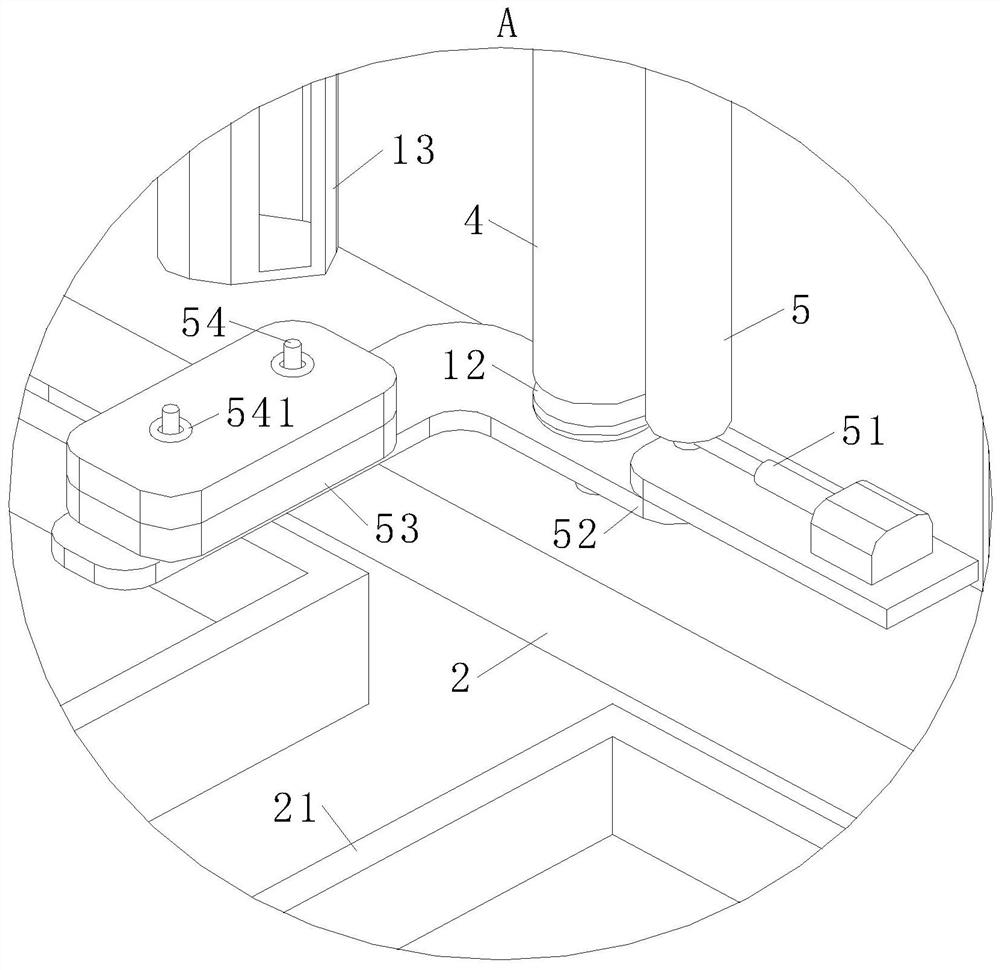

[0033] As an embodiment of the present invention, air grooves 13 are arranged on both sides of the pull tube 1, and the wind grooves 13 are installed on the frame 2, and the wind grooves 13 are parallel to the pull tube 1; On the gray cloth between the cylinders 1, the fan in the air groove 13 provides the airflow blown out to prevent the diffused moist air flow in the airflow groove 3 from touching the drawing cylinder 1; The function of the moistening airflow increases the water content of the fibers on the surface of the gray cloth to meet the adhesion effect of the slurry on the surface of the gray cloth during the printing process, and the moistening gas emitted in the air flow groove 3 will also float to the area of the puller 1, containing moisture The gas attached to the surface of the drawing cylinder 1 in the stretched state will destroy the friction force between the drawing cylinder 1 and the gray cloth, and interfere with the stable stretching effect of the drawi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com