Hydrodynamic cavitation and electrocatalysis integrated antibiotic wastewater degradation device

A technology of antibiotic wastewater and hydraulic cavitation, applied in water/sewage treatment, water/sewage multi-stage treatment, oxidized water/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

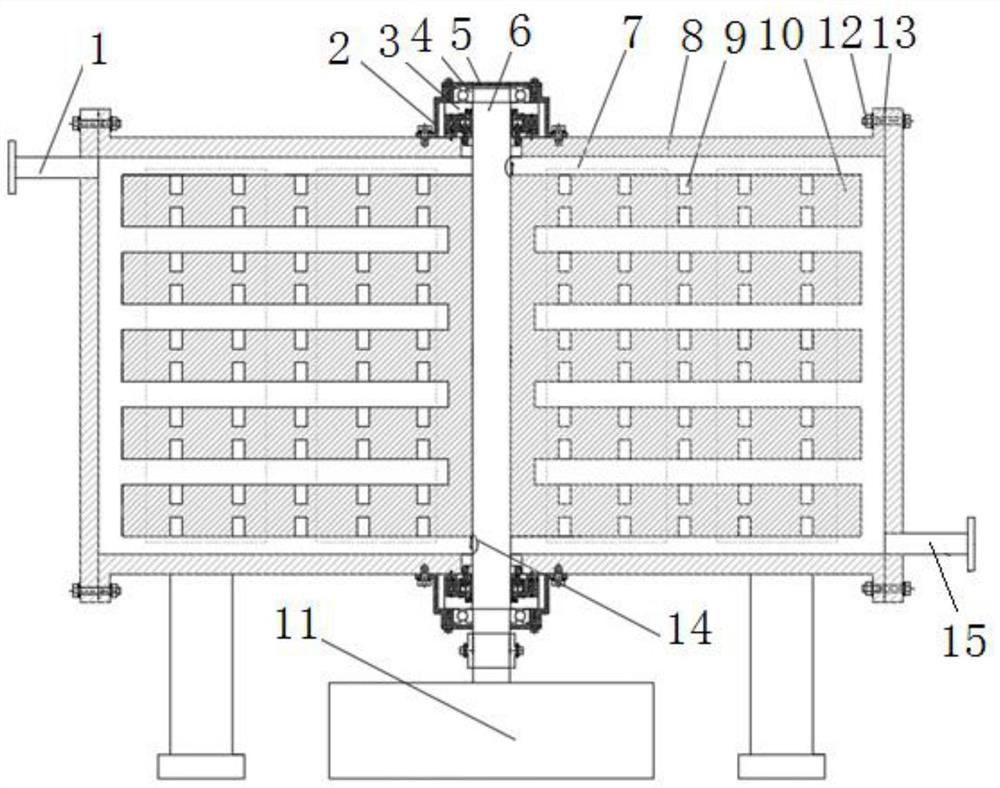

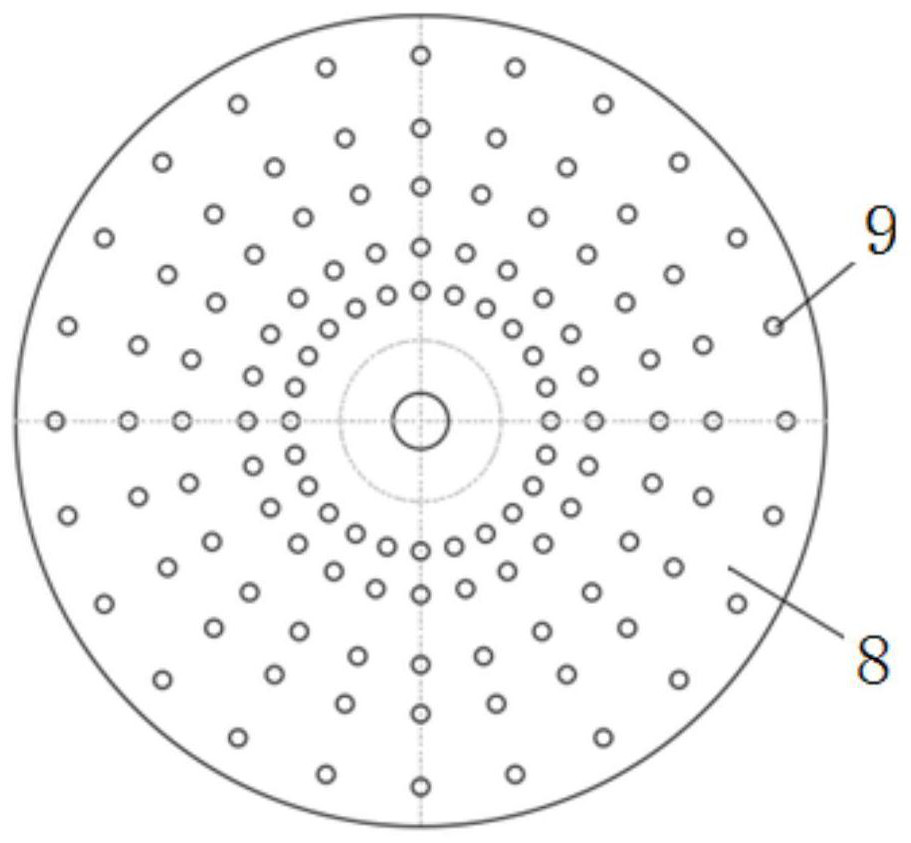

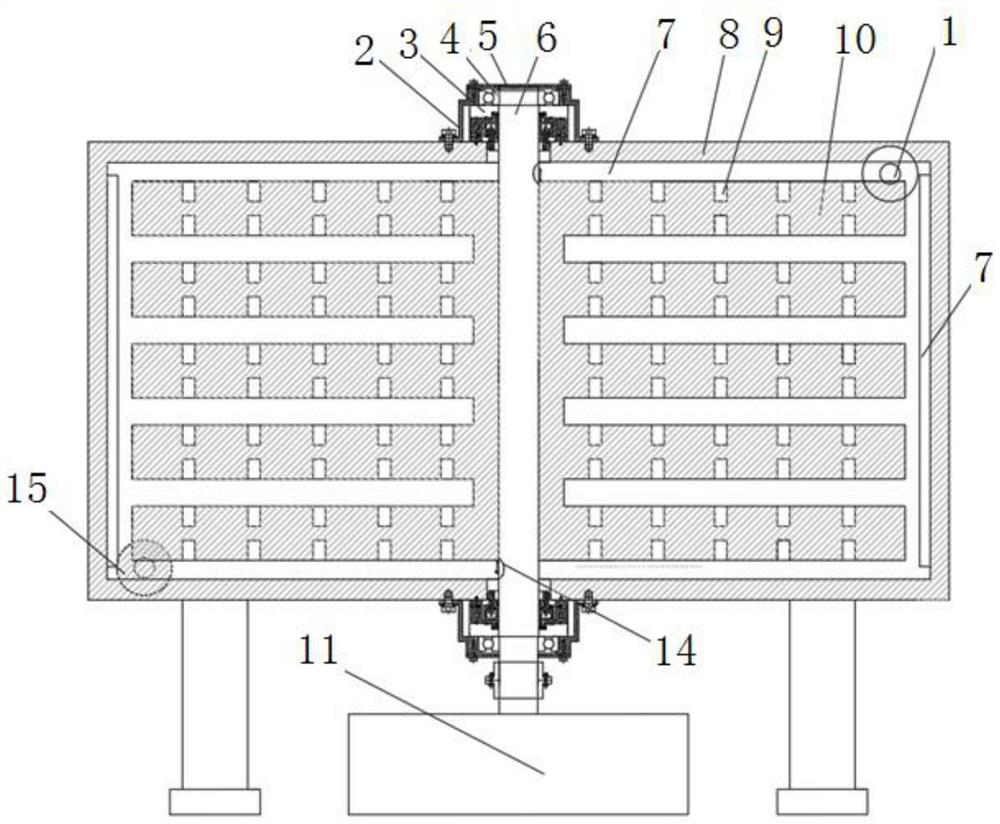

[0044] The device for hydrodynamic cavitation combined with electrocatalytic degradation of antibiotics of the present invention, such as figure 1As shown, it mainly includes a stator 8 , a cylindrical rotor 10 and a rotating shaft 6 . Both ends of the stator 8 are connected with end caps by bolts, and sealing washers 13 are arranged at the joints to form a closed cavity. Both ends of the stator 8 are respectively provided with bearing shells 2, and angular contact ball bearings 4 are installed in the bearing shell 2. The bearing shell 2 is connected with a sealing cover 5, and a sealing ring 13 is provided at the joint to realize sealing. Two sides of the stator 8 are respectively provided with a water inlet pipe 1 and a water outlet pipe 15 . The cylindrical rotor 10 is located in the cavitation cavity of the stator 8. The cylindrical rotor 10 is provided with 2 to 5 annular grooves, so that the rotor is divided into 3 to 6 layers in the axial direction to form a multi-laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com