Luminous sign and preparation method and application thereof

A technology of signs and uniform light panels, which is applied in the field of composite panels, can solve problems such as difficult to identify car logos, inability to realize clearly visible car logos, and great environmental hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

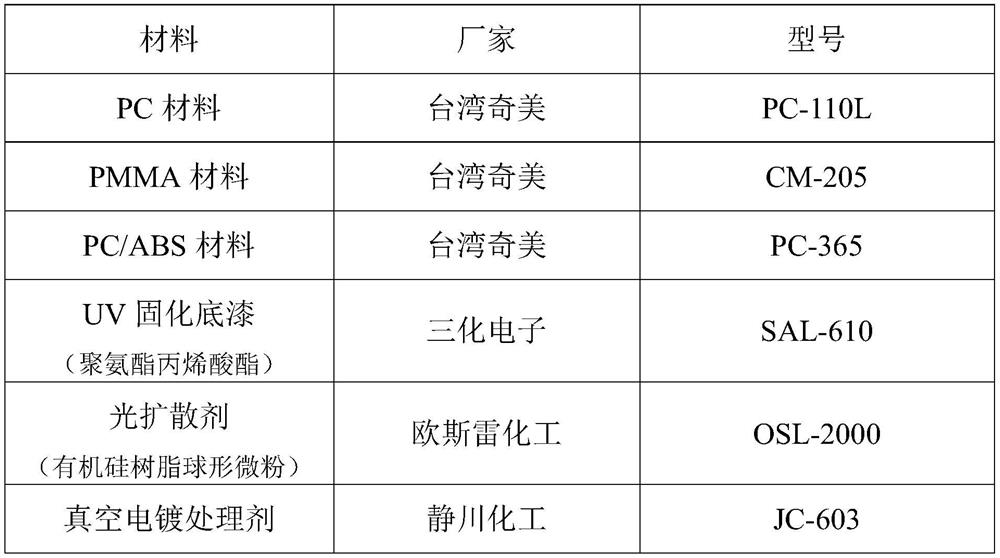

Embodiment 1

[0055] A luminous vehicle logo, which is composed of a bottom case, a circuit board, a uniform light plate, a logo body and a decorative board arranged in sequence;

[0056] Among them, the bottom shell and the decorative board are made of PC / ABS composite material, and LED lamp beads are welded on the circuit board. The total brightness of all LED lamp beads is 40cd / m 2 , The preparation raw material of uniform plate is 90wt% of PC and 10wt% of light diffusing agent; the sign body is composed of 0.18 μm aluminum electroplating layer, 14 μm primer layer and sign base.

[0057] The preparation method is as follows:

[0058] (1) Choose transparent PC material, and inject to obtain the sign base with a thickness of 2.5mm;

[0059] (2) The inner surface of the sign base is first wiped with white electric oil, then sprayed with a vacuum plating treatment agent to a thickness of 5 μm, and then sprayed with a primer with a thickness of 14 μm, and finally placed in a vacuum coating m...

Embodiment 2-3

[0065] The difference from Example 1 is that in this example, the thickness of the aluminum electroplating layer is 0.10 μm (Example 2) and 0.25 μm (Example 3).

Embodiment 4-5

[0067] The difference from Example 1 is that in this example, the raw materials for preparing the uniform light plate are 87wt% PC and 13wt% light diffusing agent (Example 4), 93wt% PC and 7wt% light diffusing agent (implementation Example 5).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com