Plastic powder mixer

A mixer and powder technology, applied in grain processing, etc., can solve problems such as insufficient utilization of raw materials and residual powder raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

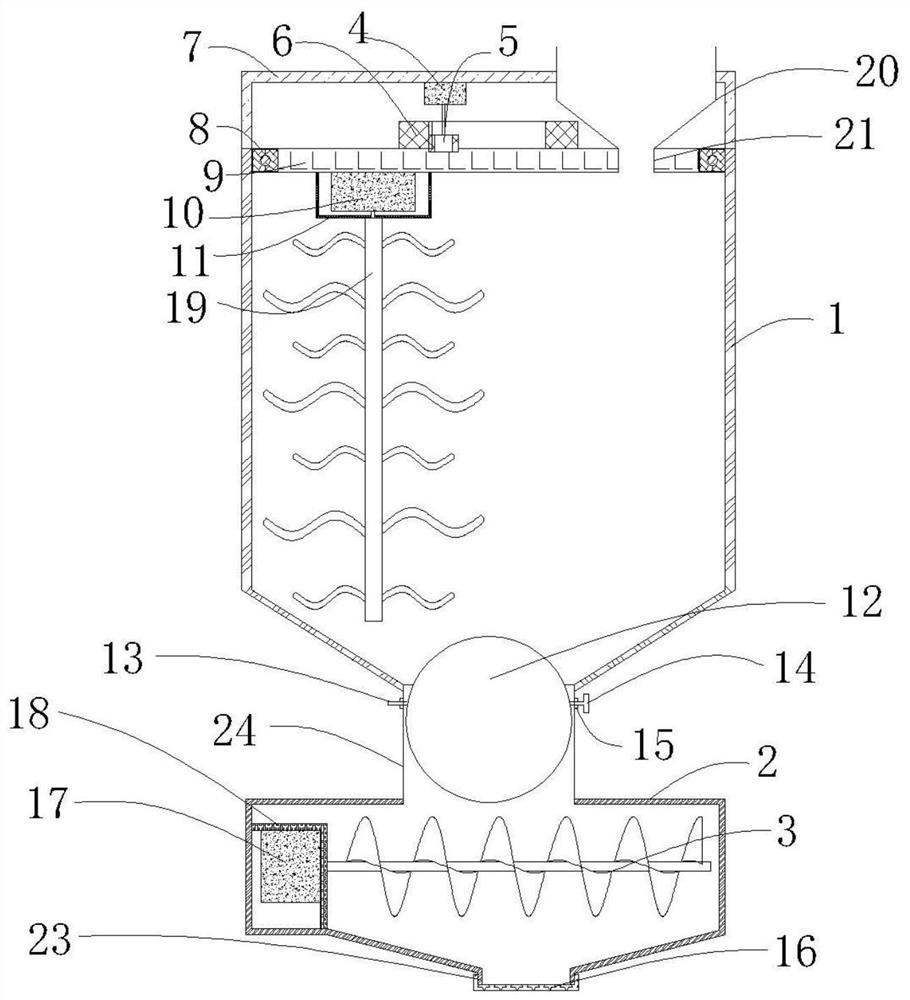

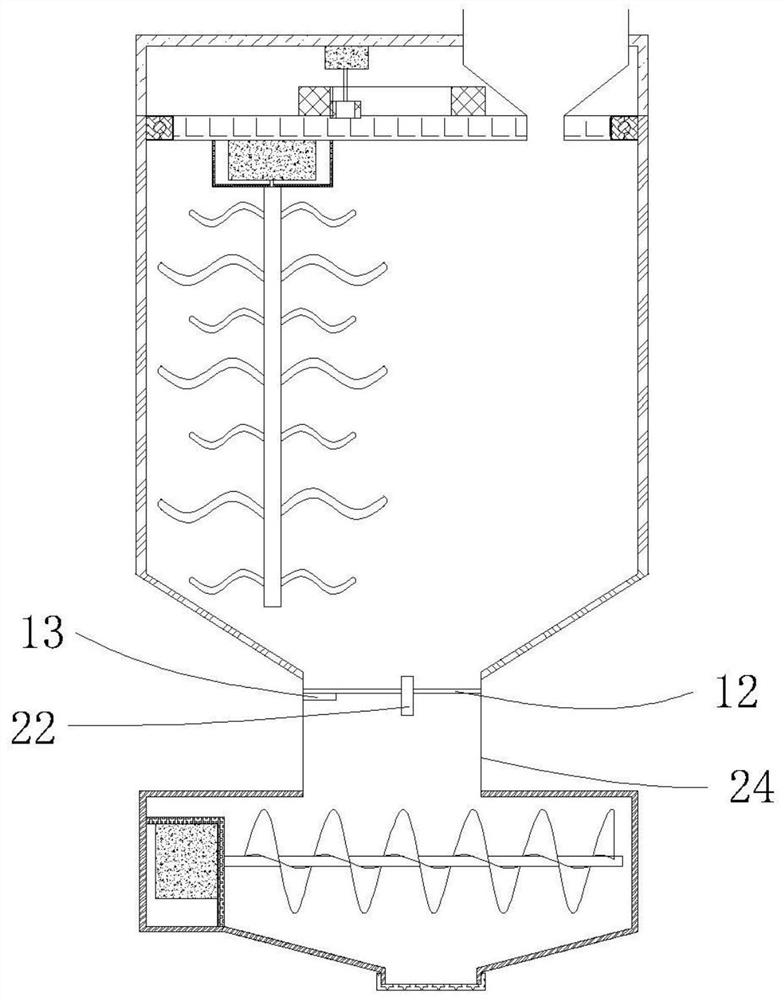

[0020] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

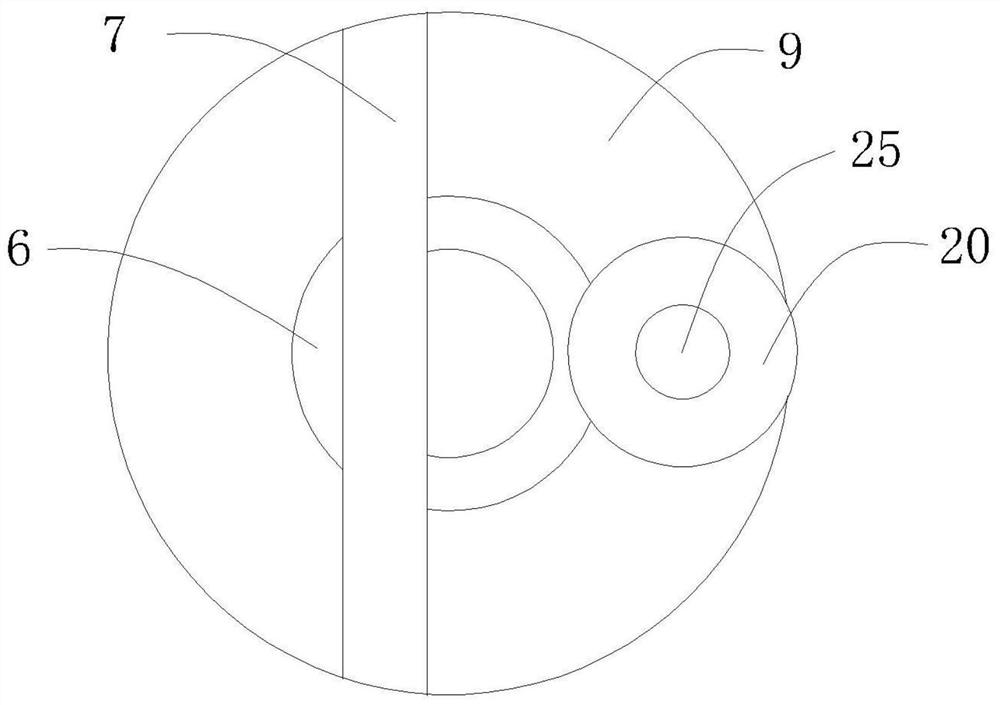

[0021] refer to figure 1 , a schematic cross-section of a plastic powder mixer Figure 1 , a plastic powder mixer, comprising a mixing bin 1, a breaking bin 2, a cover plate 9, a connecting pipe 24, a driving gear 5, a driven gear 6, a bearing 8, a partition plate 12, a fixed shaft 13, a feeding The bucket body 20, the first motor 4, the second motor 10, the feeding pipe 21, the cover plate 9 is provided with a feeding port 25, the lower end of the feeding pipe 21 passes through the feeding port 25, and the upper end of the feeding pipe 21 is fixedly connected with The feed hopper body 20 is detachably connected to the cover plate 9 by screws. The feed hopper body 20 is detachably connected to the cover plate 9, the cover plate 9 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com