A method for improving the detection accuracy of oil metal abrasive particles and its detection device

A metal abrasive particle and detection device technology, which is used in the preparation and sampling of measuring devices and test samples, can solve the problems of false signals of large abrasive particle data, and achieve the effect of improving detection accuracy and realizing miniaturized overall installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

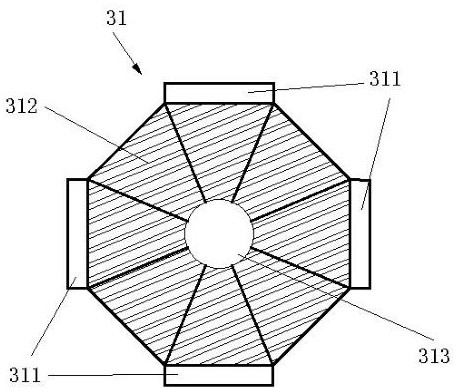

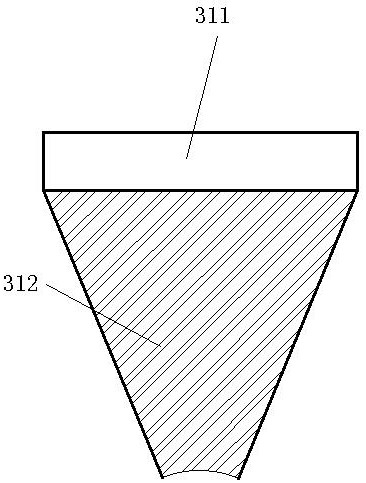

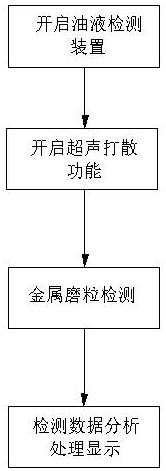

[0029] like Figures 3 to 5 As shown, a method for improving the detection accuracy of oily metal abrasive particles is used for the detection of oily metal particles in a hydraulic system. It is characterized in that the used oily metal abrasive particle detection device includes a first oily metal abrasive particle detection sensor. and an ultrasonic stirring and dispersing device arranged at the front end of the first oil metal abrasive particle detection sensor, the specific steps are as follows:

[0030] a. Open the detection device: install the oil metal abrasive particle detection device on the pipe port, let the oil to be detected flow through the detection device, and open the oil metal abrasive particle detection device;

[0031] b. Turn on the ultrasonic dispersing function: turn on the function of the ultrasonic stirring and dispers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com