Modified metal supported catalyst, diaminodicyclohexylmethane product and preparation method and application of diaminodicyclohexylmethane product

A technology of diaminodicyclohexylmethane and diaminodiphenylmethane, which is applied in the fields of diaminodicyclohexylmethane products and their preparation, and modified metal-supported catalysts, can solve the problem of increasing investment in processes and equipment, potential safety hazards, and equipment Corrosion etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] In a 2 L volume autoclave with built-in filter, add 6 g of Rh / Al with a metal content of 4 wt % 2 o 3 Catalyst, add the MDA-100 of 400g and tetrahydrofuran of 267g simultaneously, use the N of 10bar (absolute pressure) 2 After three replacements, use 10bar (absolute pressure) of H 2 Replaced three times, then H 2 Make up the pressure to 45-50bar (absolute pressure). Raise the temperature to 180°C, and continuously feed H into the reactor through the hydrogen flow controller during the reaction. 2 , to ensure that the reaction pressure is maintained at 60bar (absolute pressure), when the hydrogen flow rate indication by the hydrogen flow controller is lower than 100sccm, stop feeding H 2 , When the pressure drop of the reactor is less than 0.1bar / min, stop the reaction, and lower the temperature and release the pressure of the reactor. When the temperature of the reactor drops to 50°C, use no more than 6bar (absolute pressure) of N 2 The product liquid and the cata...

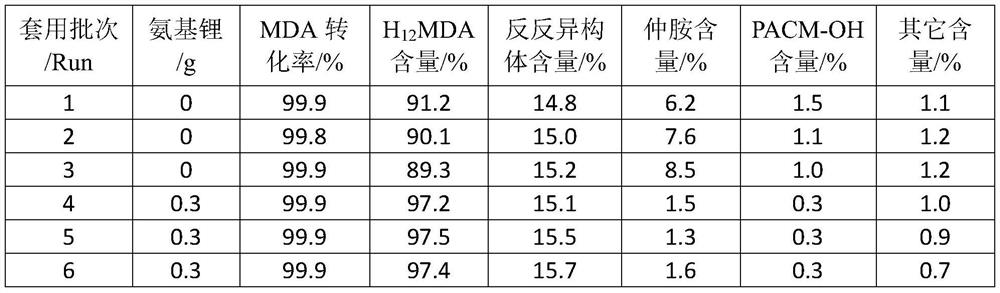

Embodiment 2

[0065] In a 2 L autoclave with built-in filter, 10 g of Rh / Al with a metal content of 4 wt % 2 o 3 Catalyst, add 500g MDA-85 and 500g tetrahydrofuran simultaneously, use the N of 10bar (absolute pressure) 2 After three replacements, use 10bar (absolute pressure) of H 2 Replaced three times, then H 2 Make up the pressure to 45-50bar (absolute pressure). Raise the temperature to 190°C, and continuously feed H into the reactor through the hydrogen flow controller during the reaction. 2 , to ensure that the reaction pressure is maintained at 80bar (absolute pressure), when the hydrogen flow rate indication by the hydrogen flow controller is lower than 100sccm, stop feeding H 2 , When the pressure drop of the reactor is less than 0.1bar / min, stop the reaction, and lower the temperature and release the pressure of the reactor. When the temperature of the reactor drops to 50°C, use no more than 6bar (absolute pressure) of N 2 The product liquid and the catalyst are filtered and...

Embodiment 3

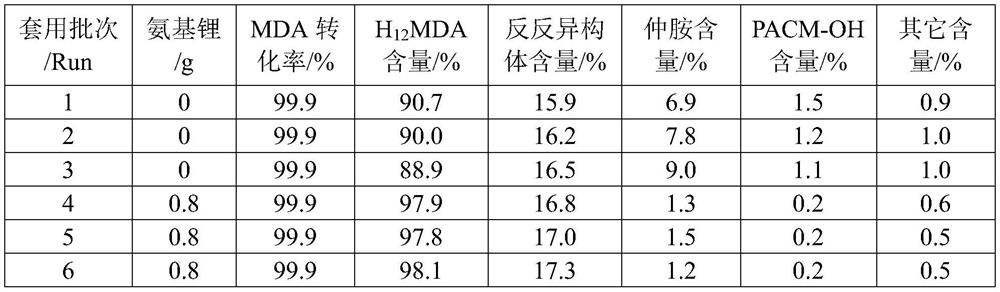

[0070] Beginning at the 7th batch of embodiment 1, the addition amount of every batch of lithium amide drops to 0.06g, all the other conditions are the same as embodiment 1. The results obtained are shown in Table 3.

[0071] Catalyst application reaction result of table 3 embodiment 3

[0072]

[0073] As can be seen from Table 3, when applying mechanically for the 7th-9th time, add 1wt% (in Rh / Al 2 o 3 By weight) lithium amide, compared with the 4-6 batches, the secondary amine content has no significant change, while the PACM-OH content rises slightly, H 12 The content of MDA was slightly reduced, but compared with no addition of lithium amide, H 12 MDA content is still significantly improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com