Diatom ooze preparation machine for house building engineering and using method thereof

A technology of diatom mud and preparation machines, which is applied in chemical instruments and methods, mixers, chemical/physical processes, etc., can solve the problems of large driving torque, large stirring load, difficult driving, etc., and achieve the effect of high-quality preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

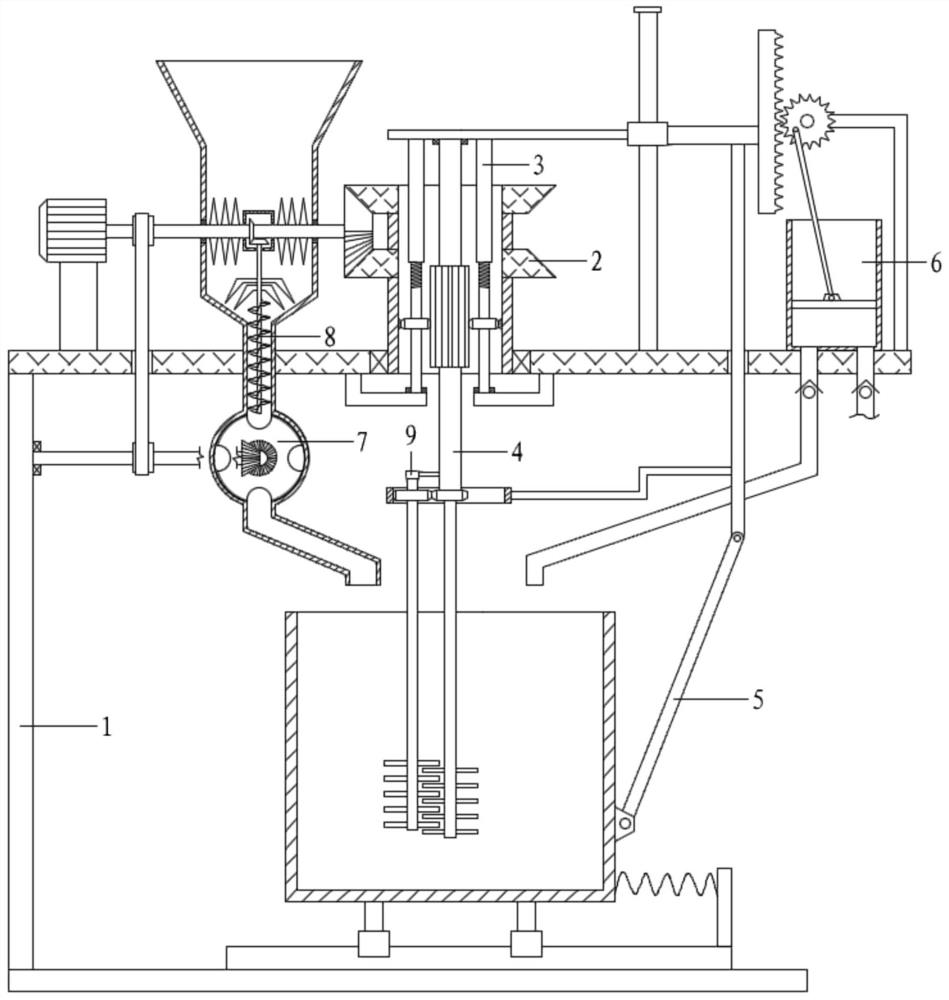

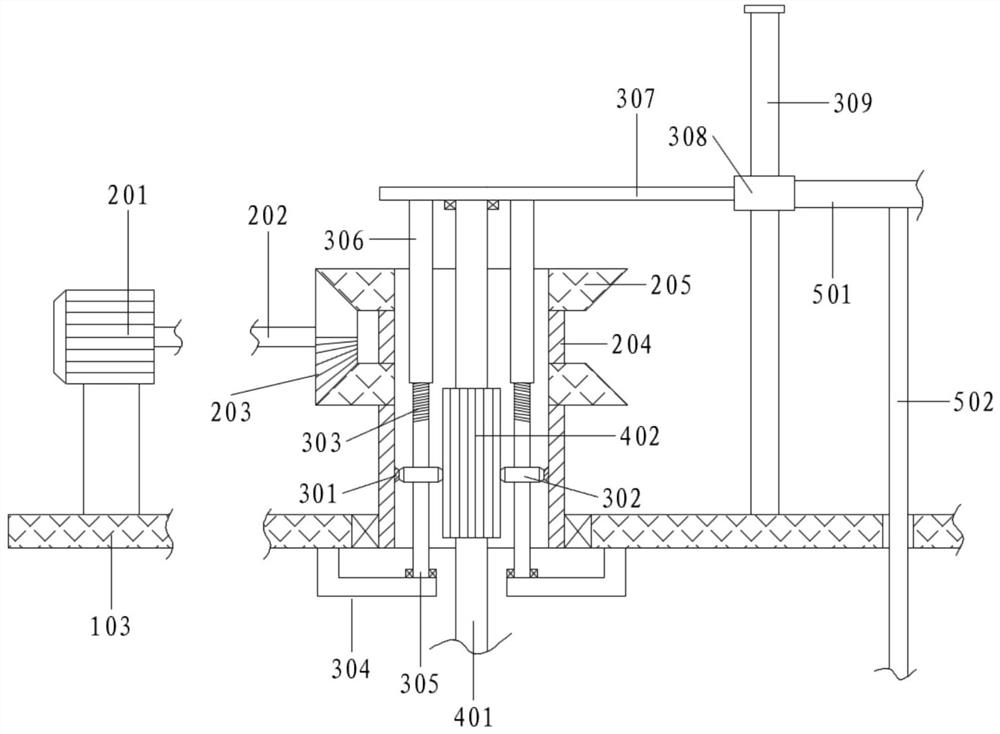

[0067] With reference to the accompanying drawings, a diatom mud preparation machine for housing construction projects includes a frame assembly 1, a reciprocating assembly 2, a lifting assembly 3, a first-class stirring assembly 4, a push-pull assembly 5, a water adding assembly 6, and a feeding assembly 7;

[0068] The frame assembly 1 includes a bottom plate 101, a side plate 102, a top plate 103, a hopper 104, a feed pipe 105, a quantitative cavity 106, a feeding pipe 107 and a preparation box 108; the top plate 103 is arranged above the bottom plate 101, and the left ends of the two pass through the side plate 102 connection; the top plate 103 is provided with a reciprocating assembly 2, and the reciprocating assembly 2 is equipped with a lifting assembly 3; a preparation box 108 is arranged above the bottom plate 101, and the right side of the lifting assembly 3 is connected with the preparation box 108 through a push-pull assembly 5; Cooperate with a first-class stirring...

Embodiment 2

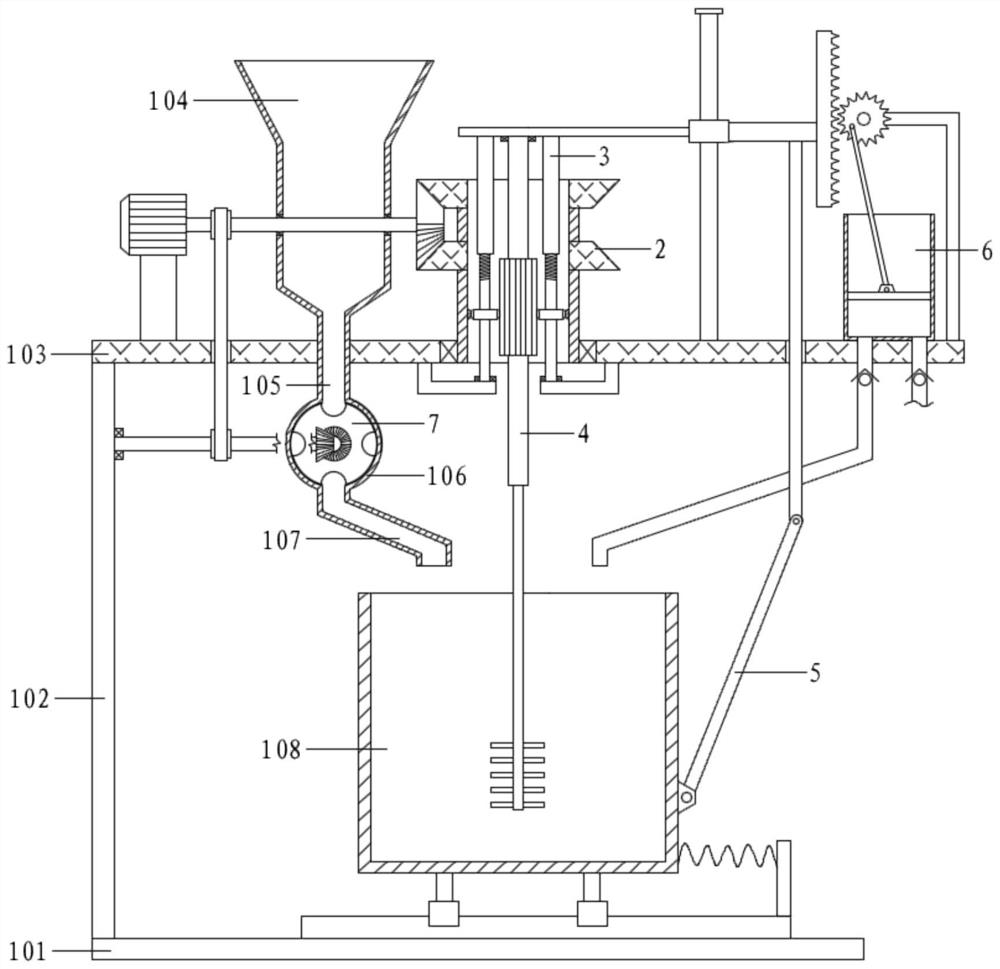

[0070] With reference to the accompanying drawings, a diatom mud preparation machine for housing construction projects includes a frame assembly 1, a reciprocating assembly 2, a lifting assembly 3, a first-class stirring assembly 4, a push-pull assembly 5, a water adding assembly 6, and a feeding assembly 7;

[0071] The frame assembly 1 includes a bottom plate 101, a side plate 102, a top plate 103, a hopper 104, a feed pipe 105, a quantitative cavity 106, a feeding pipe 107 and a preparation box 108; the top plate 103 is arranged above the bottom plate 101, and the left ends of the two pass through the side plate 102 connection; the top plate 103 is provided with a reciprocating assembly 2, and the reciprocating assembly 2 is equipped with a lifting assembly 3; a preparation box 108 is arranged above the bottom plate 101, and the right side of the lifting assembly 3 is connected with the preparation box 108 through a push-pull assembly 5; Cooperate with a first-class stirring...

Embodiment 3

[0096] The diatom ooze solid raw material may have agglomeration, which will cause the problem of unsmooth feeding, so on the basis of embodiment 2, a material guide assembly 8 is also set;

[0097] The guide assembly 8 includes a gear box 801, a No. 3 bevel gear 802, a No. 4 bevel gear 803, a guide shaft 804, a fixed frame and an auger 805;

[0098] A gear box 801 is fixed in the feeding hopper 104 through rods; the No. 1 rotating shaft 202 extends into the feeding hopper 104 and runs through the gear box 801. The No. 1 rotating shaft 202 is fixedly connected with the No. 3 bevel gear 802, and the No. 3 bevel gear 802 is arranged on the gear box. Inside 801; No. 3 bevel gear 802 is vertically meshed with No. 4 bevel gear 803, and No. 4 bevel gear 803 is fixedly connected to the top of material guide shaft 804; And installed with screw auger 805.

[0099] Specifically, the No. 1 rotating shaft 202 also drives the No. 3 bevel gear 802 to rotate, and through the rotation of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com