Environment-friendly industrial waste gas purification and cyclic utilization equipment

An industrial waste gas and environmental protection technology, which is applied in the direction of lighting and heating equipment, waste heat treatment, process efficiency improvement, etc., can solve the problems of increasing device manufacturing costs and reducing heat energy recovery benefits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

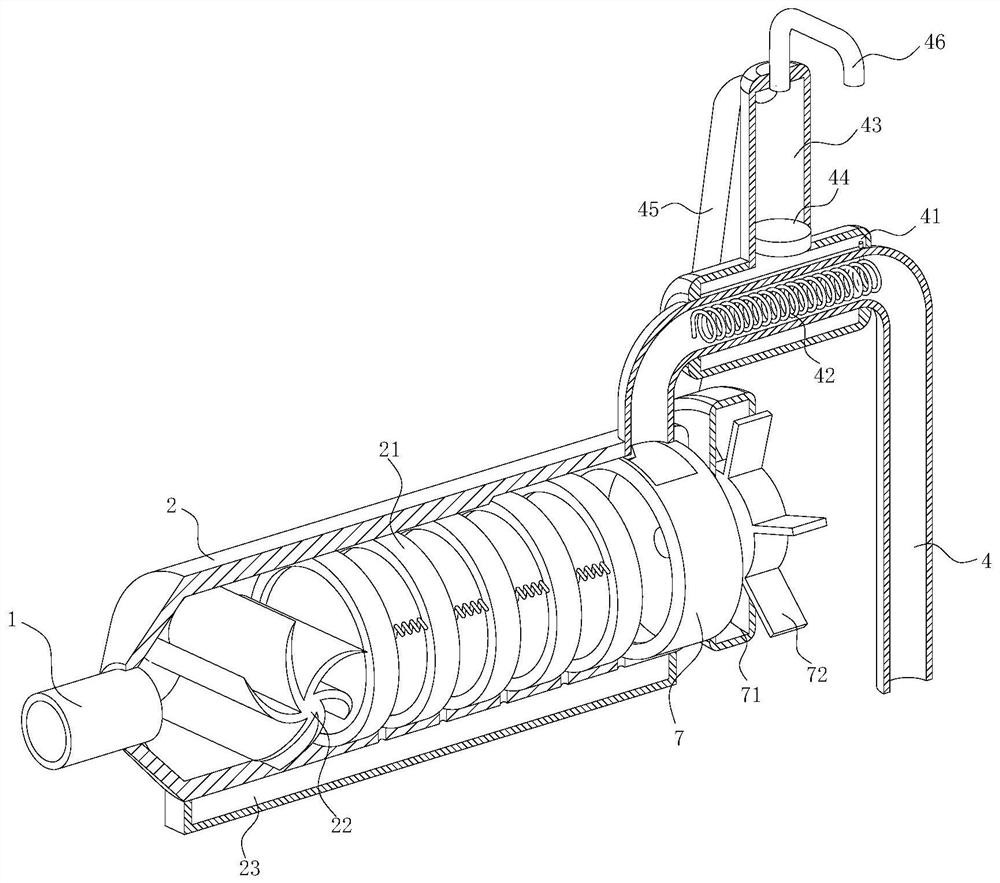

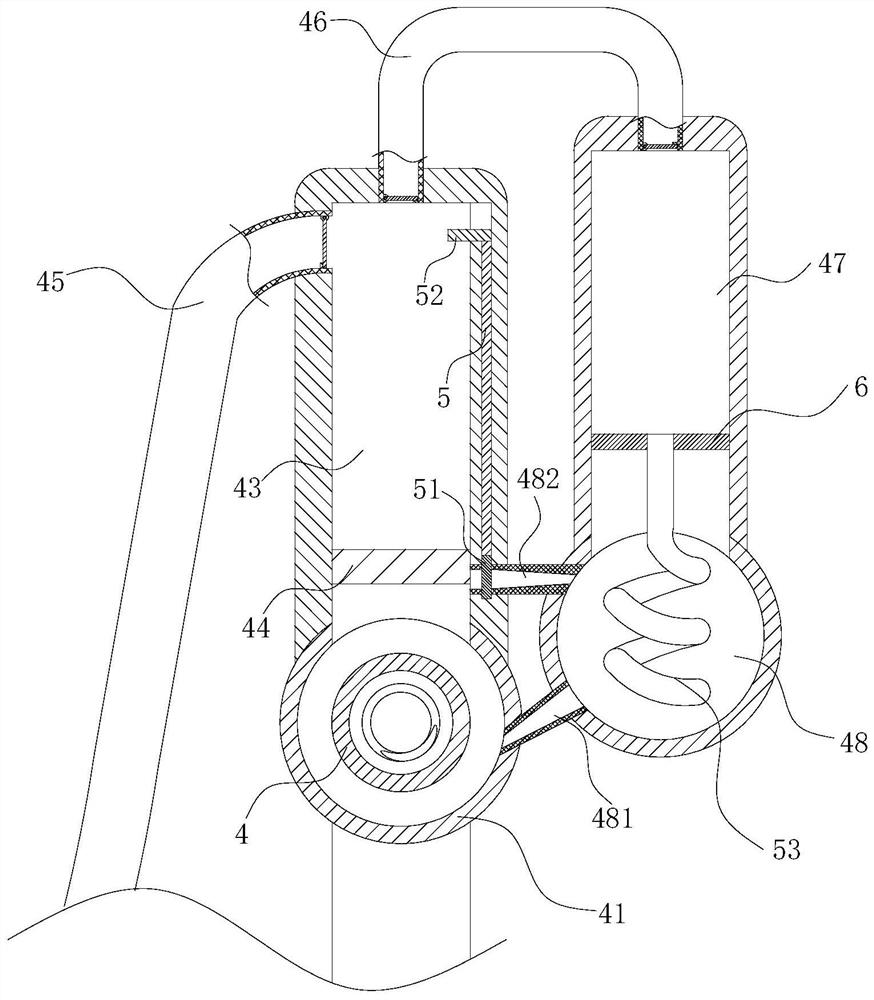

[0025] As an embodiment of the present invention, the end of the dust removal chamber 2 away from the intake pipe 1 is rotatably connected with a rotating shaft; the rotating shaft extends to the outside of the dust removal chamber 2; Rotating ring 7; the rotating ring 7 fits the inner diameter of the dust removal chamber 2; the side wall of the rotating ring 7 is provided with symmetrically designed first through grooves; the two first through grooves occupy three thirds of the rotating ring 7 circumference One; the end of the dust removal chamber 2 away from the intake pipe 1 is fixedly connected with a transmission chamber 71 through a guide rod; the rotating shaft extends into the transmission chamber 71; the rotating shaft is located in the transmission chamber 71 and is fixedly connected with a rotating fan blade 72 The transmission chamber 71 communicates with the guide pipe 53 and the transmission chamber 71 is located between the cooling pipe 48 and the heat exchange c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com