A kind of hydroxyapatite composite material with antibacterial function and its preparation method and application

A technology of hydroxyapatite and composite materials, applied in medical preparations containing active ingredients, medical preparations with non-active ingredients, applications, etc., can solve the problems that the research on iodine-modified hydroxyapatite has not been reported, etc. Achieve good regenerative repair effect and improve biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

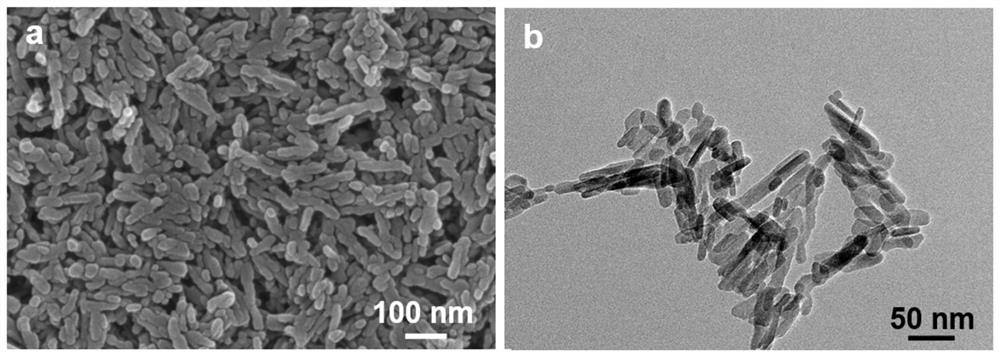

[0074] (1) Hydroxyapatite is purchased or prepared by chemical precipitation. The preparation method is: weigh 13.875g of anhydrous calcium chloride and dissolve it in 750mL of water, adjust the pH to 9.5 with ammonia water, stir for 30min, and add 250mL of 0.3 M(NH 4 ) 2 HPO 4 Aqueous solution, the pH of the solution is controlled to be 9-10 during the dropping process, then stirred and reacted at 75°C for 12-24 hours, centrifuged, washed alternately with water and ethanol for several times, and dried to obtain the following: figure 1 Hydroxyapatite shown.

[0075] (2) Ultrasonic disperse 5g of hydroxyapatite in 100mL of ethanol, add ammonia water to adjust the pH to 10, add 3g of 3-aminopropyltriethoxysilane, stir at 300rpm and reflux at 75°C for 24h, centrifuge, wash with ethanol Washed twice, dried in vacuum to obtain amino-functionalized hydroxyapatite.

[0076] (3) Dissolve 10g of 6-O-carboxymethyl chitosan (average weight-average molecular weight of 150,000g / mol, de...

Embodiment 2

[0084]Repeat steps (1)(2)(3) in Example 1 to prepare amino-functionalized hydroxyapatite and quaternized carboxymethyl chitosan, the difference is only to select the 6- O-carboxymethyl chitosan (deacetylation degree ≥ 85%, substitution degree ≥ 80%).

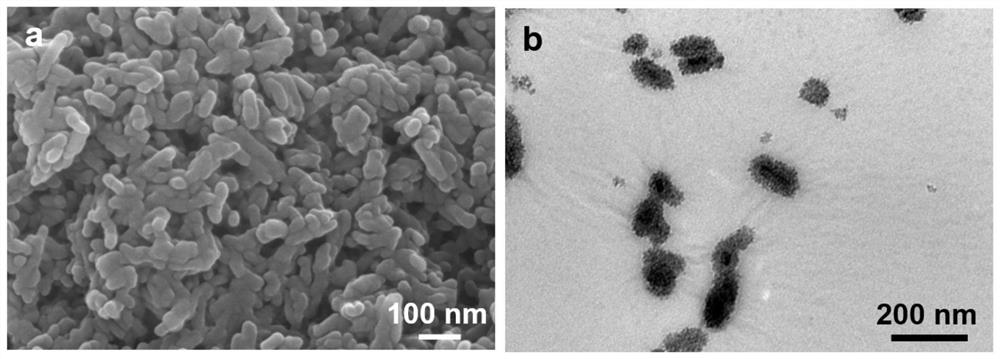

[0085] (4) Ultrasonic disperse 1g of amino-functionalized hydroxyapatite in 130mL of water, add 0.65g of quaternized carboxymethyl chitosan to completely dissolve, mix well, add 6.85mL of 100 / 50mM EDC / NHS mixture drop by drop Add in the above solution, the final concentration is 5.0 / 2.5mM, cross-link at room temperature for 24h, the cross-linked solution is centrifuged and washed, and freeze-dried to obtain the surface grafted quaternized carboxymethyl chitosan material (HA -g-GCMC).

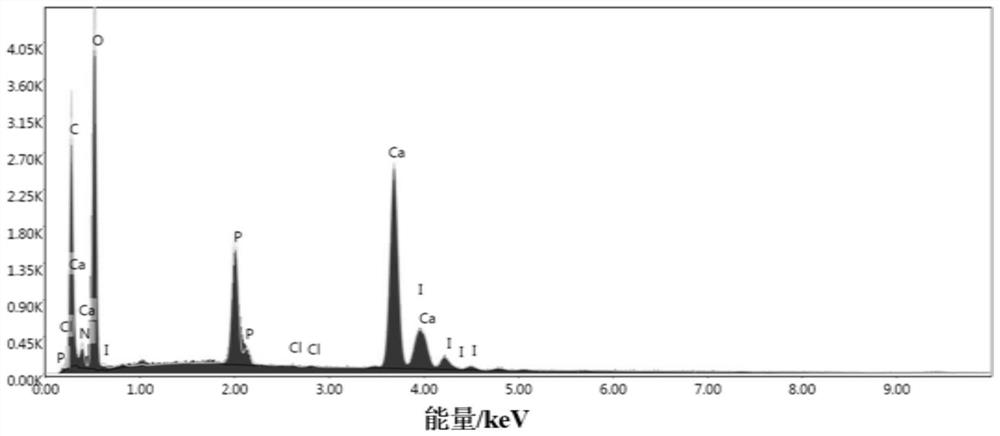

[0086] (5) Immerse the obtained HA-g-GCMC in 50mL of 0.01g / mL iodine / ethanol / water (volume ratio of ethanol to water is 1:3), stir at room temperature for 5h, wash and freeze-dry to obtain antibacterial hydroxyphosphorus Gray stone composite mat...

Embodiment 3

[0089] Repeat steps (1)(2)(3) in Example 1 to prepare amino functionalized hydroxyapatite and quaternized carboxymethyl chitosan, the difference is only that the selection of average weight average molecular weight is 1000g / mol of 6- O-carboxymethyl chitosan (deacetylation degree ≥ 85%, substitution degree ≥ 80%).

[0090] (4) Ultrasonic disperse 1g of amino-functionalized hydroxyapatite in 300mL of water, add 1.5g of quaternized carboxymethyl chitosan to dissolve completely, mix well, add 15.80mL of 200 / 100mM EDC / NHS mixture drop by drop Add in the above solution, the final concentration is 10.0 / 5.0mM, cross-linking at room temperature for 24h, the cross-linking solution, centrifugal washing, freeze-drying and drying to obtain hydroxyapatite surface grafted quaternized carboxymethyl chitosan material ( HA-g-GCMC).

[0091] (5) Immerse the obtained HA-g-GCMC in 80mL of 0.01g / mL iodine / ethanol / water (volume ratio of ethanol to water is 1:1), stir at room temperature for 5h, wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com