Loose-packed wine sauce food and preparation method thereof

A kind of bad brine and food technology, which is applied in the field of food bulk brine and its preparation, can solve the problems of too long production cycle and limit the improvement of enterprise benefits, and achieve the effects of promoting hydrolysis speed, shortening production time and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

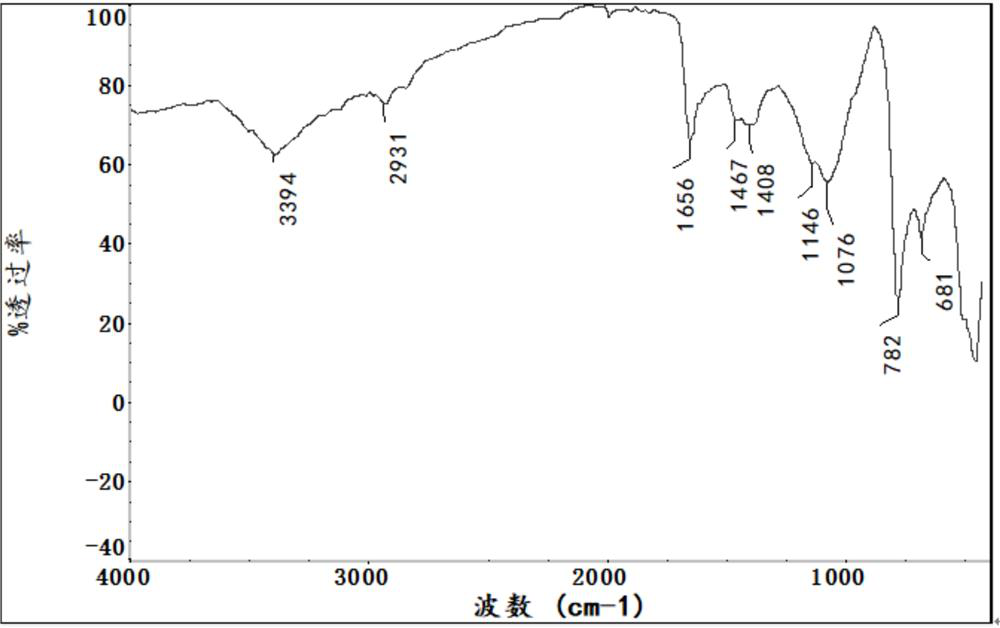

Method used

Image

Examples

Embodiment 1

[0037] A kind of food bulk bittern and preparation method thereof, its main scheme is:

[0038] Add 100kg of 3% hydrochloric acid and 0.1kg of synergist to 50kg of rice wine grains, control the temperature at 60°C and stir the reaction for 30min. After completion, use 0.1% sodium hydroxide solution to neutralize the pH value to 6.3, and then add 0.3kg of protease , temperature control at 30°C, enzymatic hydrolysis for 8 hours, after completion, filter, add 0.8kg of activated carbon to the filtrate, control the temperature at 40°C, stir for 30 minutes, and filter after completion to obtain the hydrolyzate of rice distiller's grains, add 0.8kg of mixed spices to the hydrolyzate, 2.1kg of monosodium glutamate, 2kg of sucrose and 10kg of rice wine, mixed evenly, sterilized by pasteurization, and then sealed and packaged.

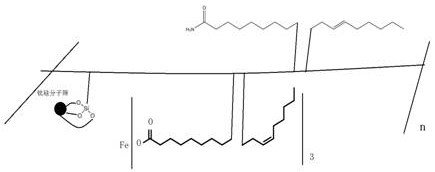

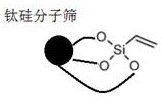

[0039] The titanium-silicon molecular sieve is a titanium-silicon molecular sieve modified by vinyltrimethoxysilane, and its preparation method is as follows: ...

Embodiment 2

[0051] A kind of food bulk bittern and preparation method thereof, its main scheme is:

[0052] Add 200kg of 7% hydrochloric acid and 0.6kg of synergist to 80kg of rice wine grains, control the temperature at 70°C and stir for 60min. After completion, use 0.3% sodium hydroxide solution to neutralize the pH value to 6.9, and then add 0.5kg of protease , control the temperature at 35°C, enzymatic hydrolysis for 10 hours, filter after completion, add 1.8kg of activated carbon to the filtrate, control the temperature at 60°C, stir for 40 minutes, and filter after completion to obtain the hydrolyzate of rice wine grains, add 2.6kg of mixed spices to the hydrolyzate, 3.6kg of monosodium glutamate, 4kg of sucrose and 13kg of rice wine, mixed evenly, sterilized by pasteurization, and then sealed and packaged.

[0053] The titanium-silicon molecular sieve is a titanium-silicon molecular sieve modified by vinyltrimethoxysilane, and its preparation method is as follows:

[0054] 25g of ...

Embodiment 3

[0065] A kind of food bulk bittern and preparation method thereof, its main scheme is:

[0066] Add 300 kg of 10% hydrochloric acid and 1 kg of synergist to 100 kg of rice wine grains, control the temperature at 80°C and stir for 120 minutes. After completion, use 0.5% sodium hydroxide solution to neutralize the pH value to 7.8, and then add 0.8 kg of protease. Control the temperature at 40°C, enzymatically hydrolyze for 12 hours, filter after completion, add 3kg of activated carbon to the filtrate, control the temperature at 70°C, stir for 60min, and filter after completion to obtain the hydrolyzate of rice distiller's grains, add 4kg of mixed spices and 5.3kg of monosodium glutamate to the hydrolyzate , 6kg of sucrose and 15kg of rice wine, mixed evenly, pasteurized, then sealed and packaged.

[0067] The titanium-silicon molecular sieve is a titanium-silicon molecular sieve modified by vinyltrimethoxysilane, and its preparation method is as follows:

[0068] 40g of titaniu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com