Chitosan-transition metal ion composite modified cathode material as well as preparation method and application thereof

A transition metal ion, composite modification technology, applied in battery electrodes, biochemical fuel cells, electrical components, etc., can solve the problems of increasing the size of the cathode, improving the electrochemical performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

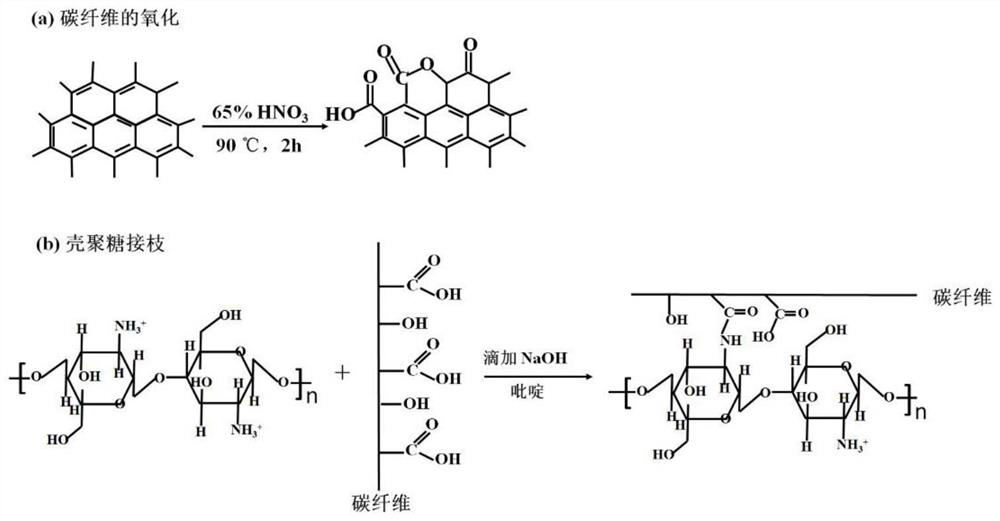

[0034] The present invention also provides a method for preparing the composite modified cathode material described in the above technical scheme, including the following steps:

[0035] The carbon raw material is subjected to heat treatment and oxidation treatment in sequence to obtain a carbon material;

[0036] Mixing the carbon material, chitosan, pyridine and alkali to perform a chemical grafting reaction to obtain a chitosan grafted carbon material;

[0037] The chitosan grafted carbon material is mixed with the transition metal ion aqueous solution, and the complexation reaction is performed to obtain the composite modified cathode material.

[0038] In the present invention, the carbon raw material is sequentially heat-treated and oxidized to obtain the carbon material.

[0039] In the present invention, the carbon material is preferably a carbon fiber brush, carbon felt, carbon rod, carbon cloth, foamed carbon, carbon nanotube or graphite carbon, and more preferably a carbon fi...

Embodiment 1

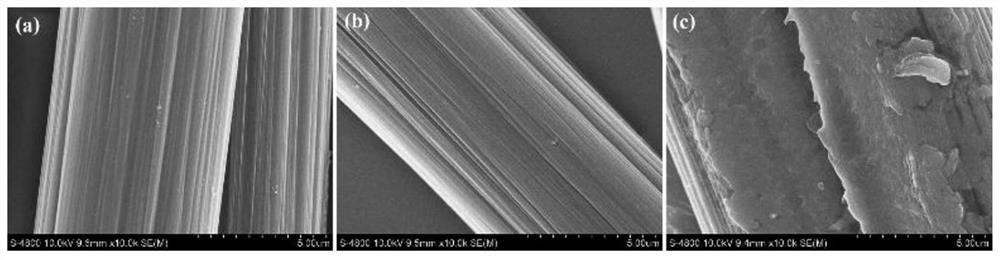

[0061] Place the carbon fiber brush (diameter 50mm, length 300mm) in a muffle furnace at 300°C for heat treatment for 1 hour, then cool it, wash it with acetone, ultrasonic vibration, and then wash it with distilled water until there is no acetone residue, to obtain a heat-treated carbon fiber brush, denoted as Blank;

[0062] Dip 10g heat-treated carbon fiber brush in 400mL of 68% concentrated nitric acid by mass, shake at 90°C for 2h, wash with water until no concentrated nitric acid remains after the oxidation reaction, and obtain an oxidized carbon fiber brush, denoted as O;

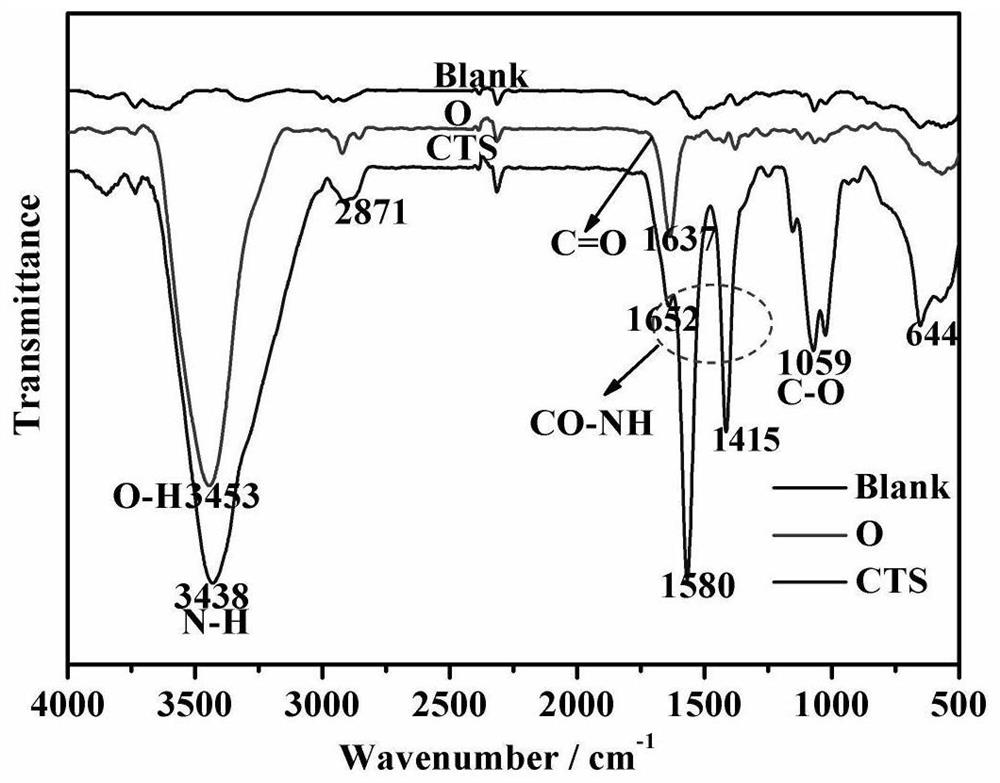

[0063] Soak 10g of oxidized carbon fiber brush in 500mL chitosan acetic acid solution (5g chitosan, 500mL distilled water, 10% acetic acid drip to completely dissolve, and drip 3~5 drops of pyridine), react at 80℃ for 2h, and react During the process, 1 mL of 0.3 mol / L sodium hydroxide was added dropwise, and after the reaction, the residual chitosan and pyridine were washed to obtain the chitosan grafted ...

Embodiment 2

[0091] Place the carbon fiber brush (diameter 25mm, length 300mm, weight 5g) in a muffle furnace at 300°C for heat treatment for 1 hour, then cool it down, wash with acetone, ultrasonic vibration, and then wash with distilled water until there is no acetone residue to get the heat-treated carbon fiber brush;

[0092] Immerse 5g of heat-treated carbon fiber brush in 400mL of 68% concentrated nitric acid by mass, shake at 90°C for 2h, wash with water until no concentrated nitric acid remains after oxidation reaction, to obtain oxidized carbon fiber brush, denoted as O;

[0093] Soak 5g of oxidized carbon fiber brush in 500mL chitosan acetic acid solution (2.5g chitosan, 500mL distilled water, 10% acetic acid drop to completely dissolve, and drop 3 drops of pyridine), react at 80℃ for 2h, the reaction process Add 5 mL of 0.3 mol / L sodium hydroxide dropwise to the mixture, and wash the residual chitosan and pyridine after the reaction to obtain the chitosan grafted carbon material, whic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com