Flexible high-precision N type thermocouple sensor cable

A thermocouple sensor, high-precision technology, used in insulated cables, thermometers, cables, etc. with electrical/magnetic components directly sensitive to heat, which can solve the problem of limiting the scope of product application, bulky, affecting on-site laying, testing and operation. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

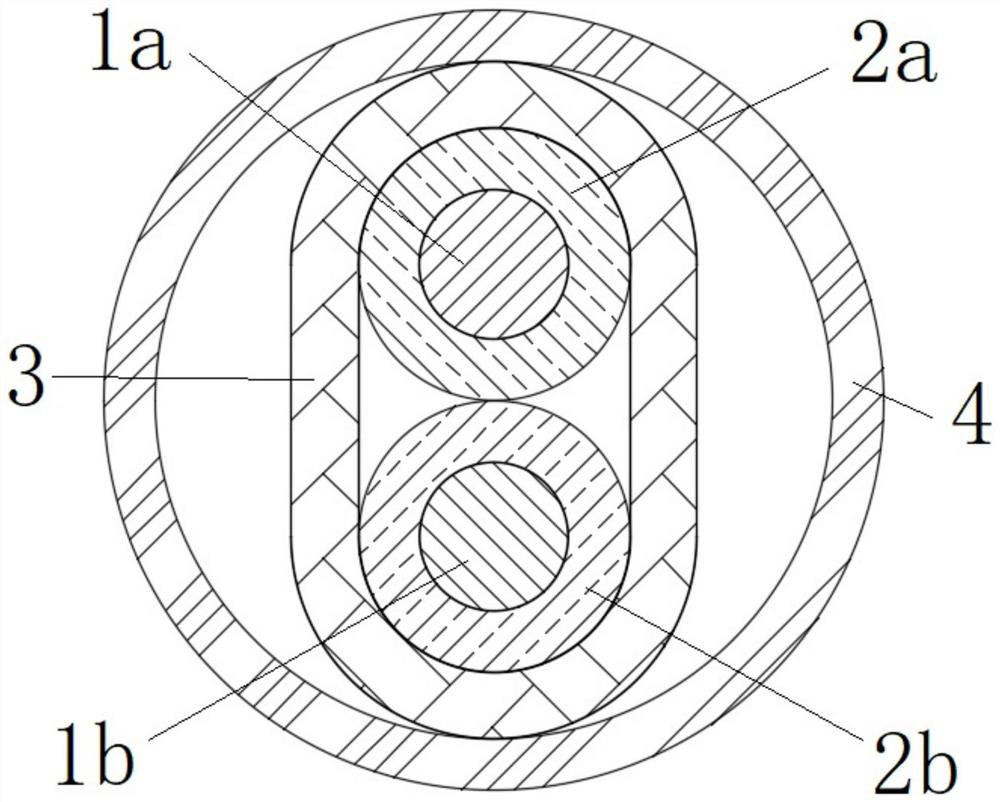

Image

Examples

Embodiment 1~3

[0034] The positive and negative electrode cores were manufactured according to the ratio shown in Table 3, and the positive and negative electrode cores were calculated at 100 wt%. The positive and negative electrode materials are made of φ0.51mm alloy materials to produce 900 meters of thermocouple cables, and then the first (reel head) and tail (reel tail) ends of the thermocouple cable are sampled, and the sampled products are welded to produce Thermocouple sensor, and then measure and calibrate the product.

[0035] Table 3: Unit: wt%

[0036]

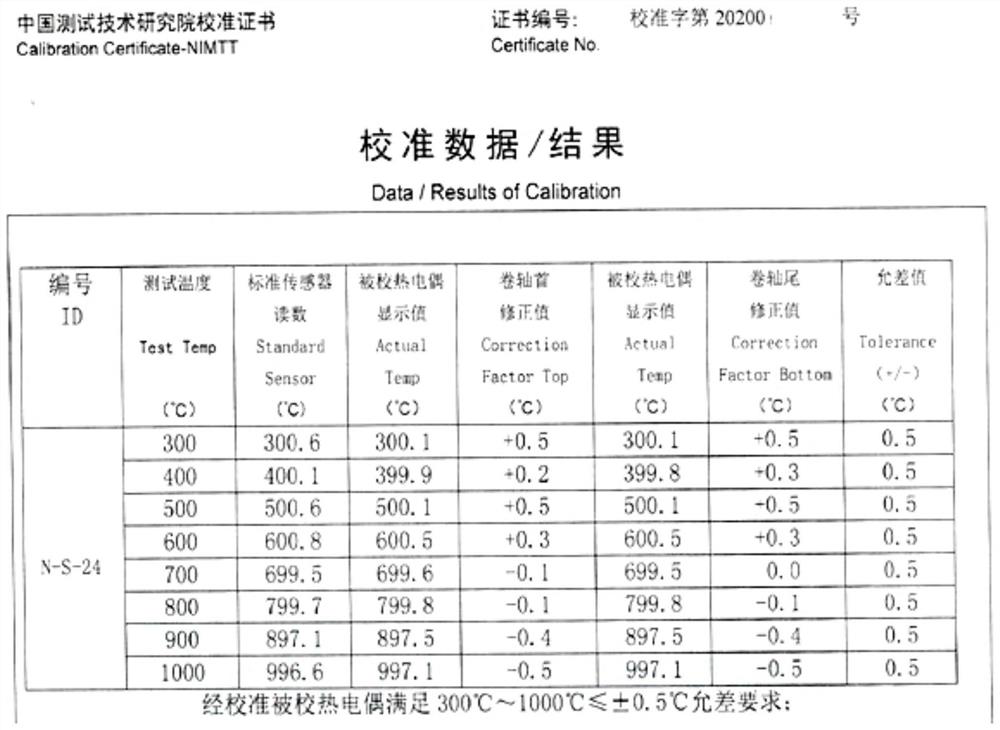

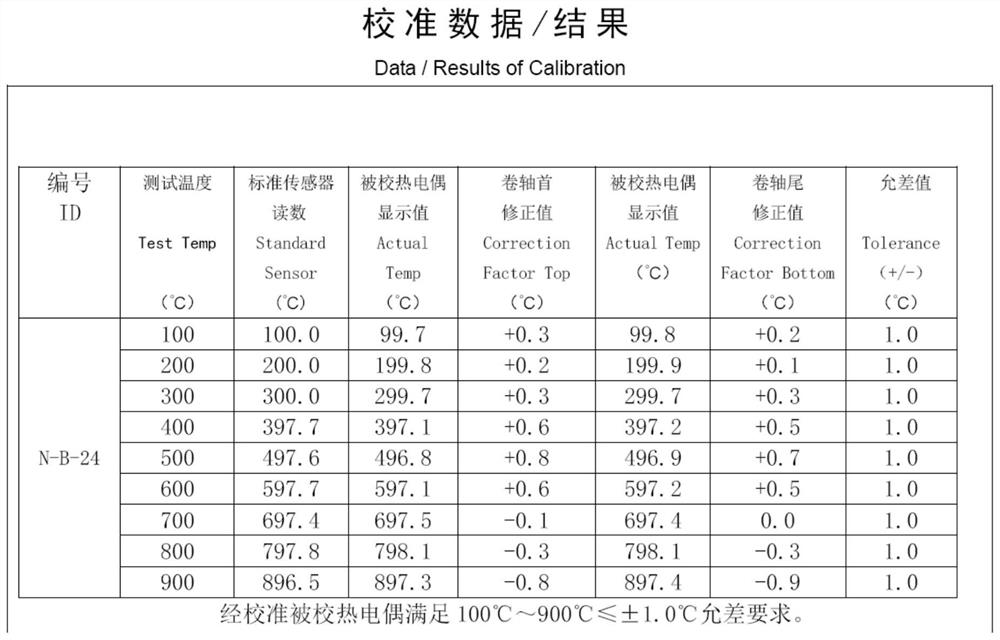

[0037] Table 4, figure 2 with image 3 The data sheet of the N-type thermocouple made in Examples 1 to 3 is calibrated once from 0°C to 1000°C.

[0038] Table 4:

[0039]

[0040] From Table 4. figure 2 with image 3 According to the third-party calibration data of the N-type thermocouple sensor cable, the temperature calibration error is within the calibration range of 0℃~1000℃, and the temperature calibration error is within ±1.0℃,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Insulation thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com