A flexible high-precision k-type thermocouple sensor cable

A thermocouple sensor, high-precision technology, applied in the direction of communication cables, insulated cables, and thermometers using electric/magnetic elements that are directly sensitive to heat, can solve the problems of bulky, poor repeated bending performance, and high overall cost. Achieve the effect of precise linear relationship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

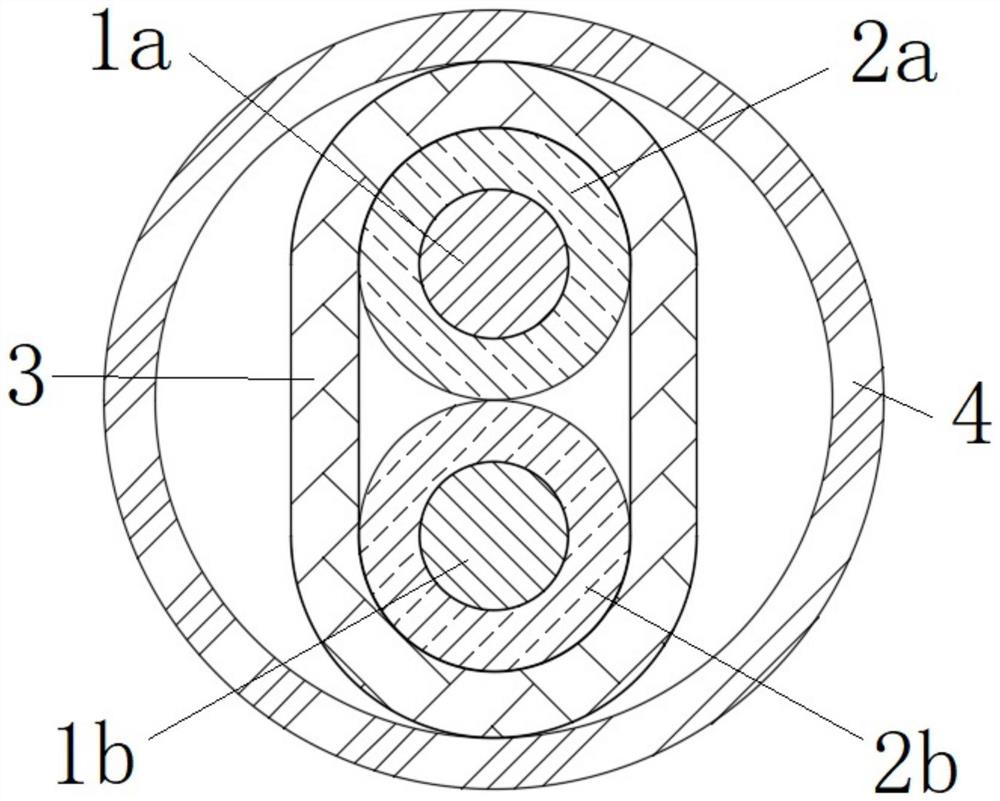

Image

Examples

Embodiment 1~3

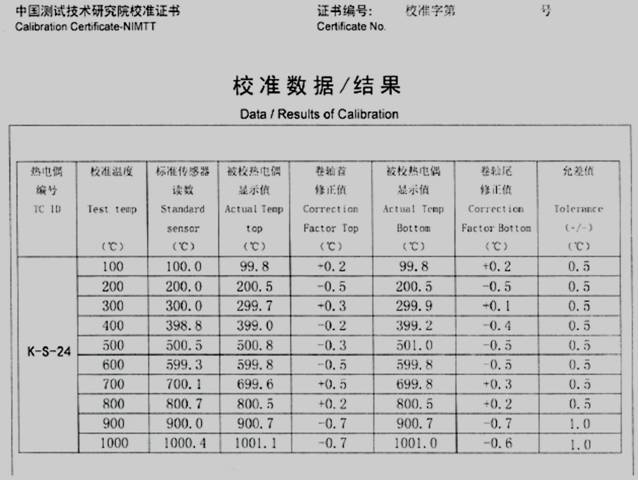

[0034] The positive and negative electrode cores were manufactured according to the ratio shown in Table 3, and the positive and negative electrode cores were calculated as 100 wt%. The positive and negative electrode materials are made of φ0.51mm alloy material to produce 900 meters of thermocouple cable, and then samples are taken from the first (reel head) and tail (reel end) of the thermocouple cable, and the sampled products are welded to produce Thermocouple sensors are then metered and calibrated to the product.

[0035] Table 3: Unit: wt%

[0036]

[0037]

[0038] Table 4 is the data table of the K-type thermocouples produced in Examples 1-3, which are calibrated once every full degree from 100°C to 1000°C.

[0039] Table 4:

[0040]

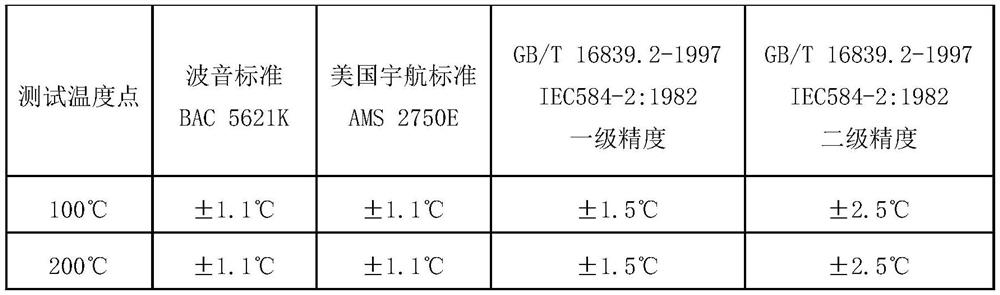

[0041] From Table 4 and figure 2 It can be known from the calibration data that the K-type thermocouple sensor cable is within the calibration range of temperature 0°C to 1000°C, and the temperature calibration error is wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com