Cold silo flow measuring device and measuring method for asphalt mixing equipment

A technology of asphalt mixture and mixing equipment, which is applied to measuring devices, weighing equipment for continuous material flow, weighing, etc., can solve problems such as increasing the labor intensity of measuring personnel, endangering the safety of measuring personnel, and wrong flow measurement results. Achieve the effects of saving manpower input, high accuracy of flow measurement, and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

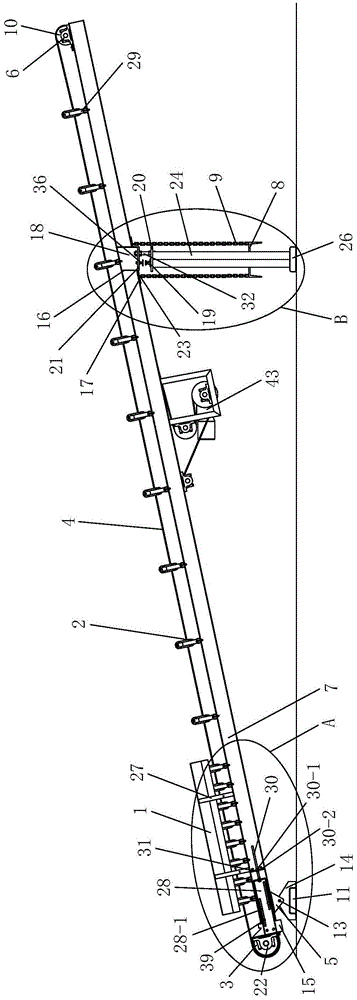

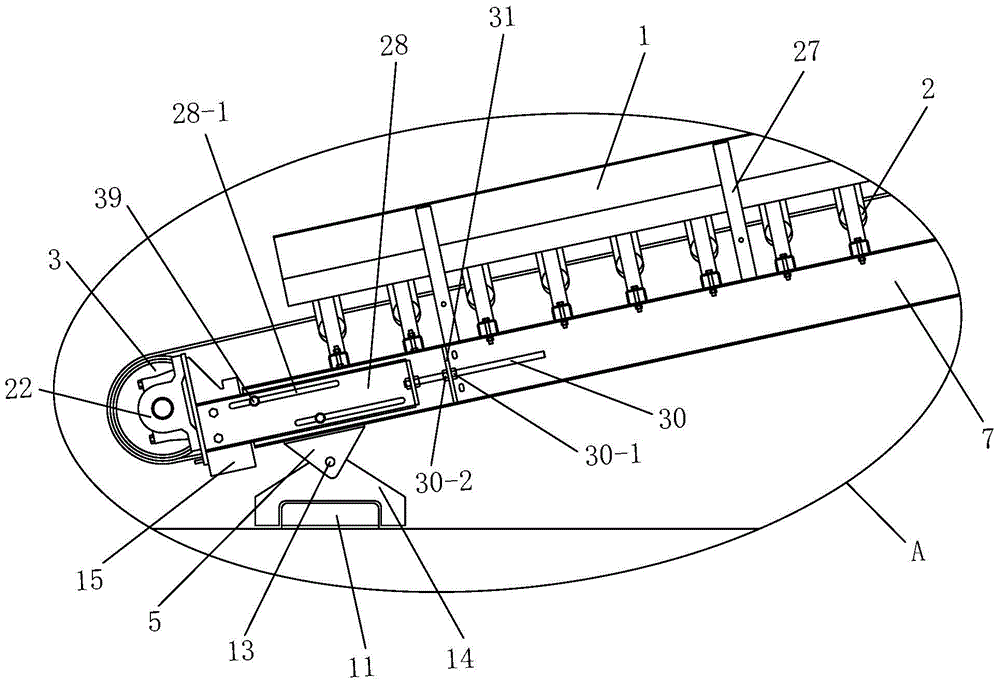

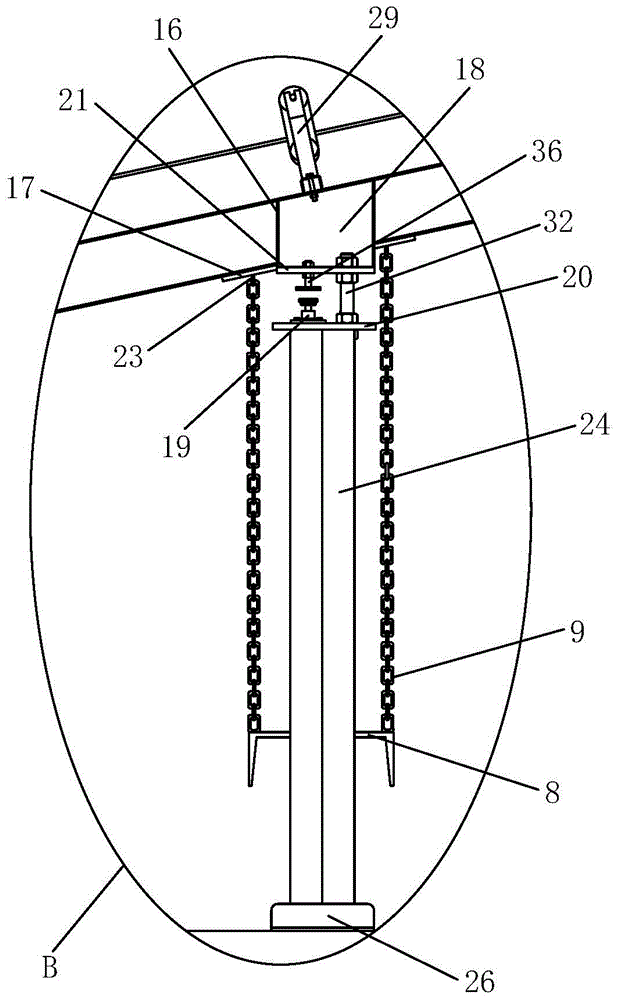

[0056] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 9 As shown, the cold material flow measuring device for the asphalt mixture mixing equipment of the present invention includes a conveyor belt frame 7 and a headstock and a tailstock that are arranged at the bottom of the conveyor belt frame 7 and are used to support the conveyor belt frame 7. The conveyor belt frame 7 is arranged obliquely, the upper end of the head frame is hinged with the lower end of the conveyor belt frame 7, the upper end of the tail frame is supported and connected with the upper end of the conveyor belt frame 7, and the lower end of the conveyor belt frame 7 is located at the Below the cold material bin 41, the bottom outlet of the cold material bin 41 to be tested is provided with a discharge belt 40 and the discharge belt 40 is driven by a frequency conversion motor to rotate, and the upper end of the conveyor belt frame 7 is rotated and installed with an upper roller 10, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com