Water soluble corrosion inhibitor for hydrogenation device and preparation method and application thereof

A hydrogenation unit and water-soluble technology, applied in the field of water-soluble corrosion inhibitor for hydrogenation unit and its preparation, can solve the problems of narrow temperature and pH range, metal content, poor corrosion resistance and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

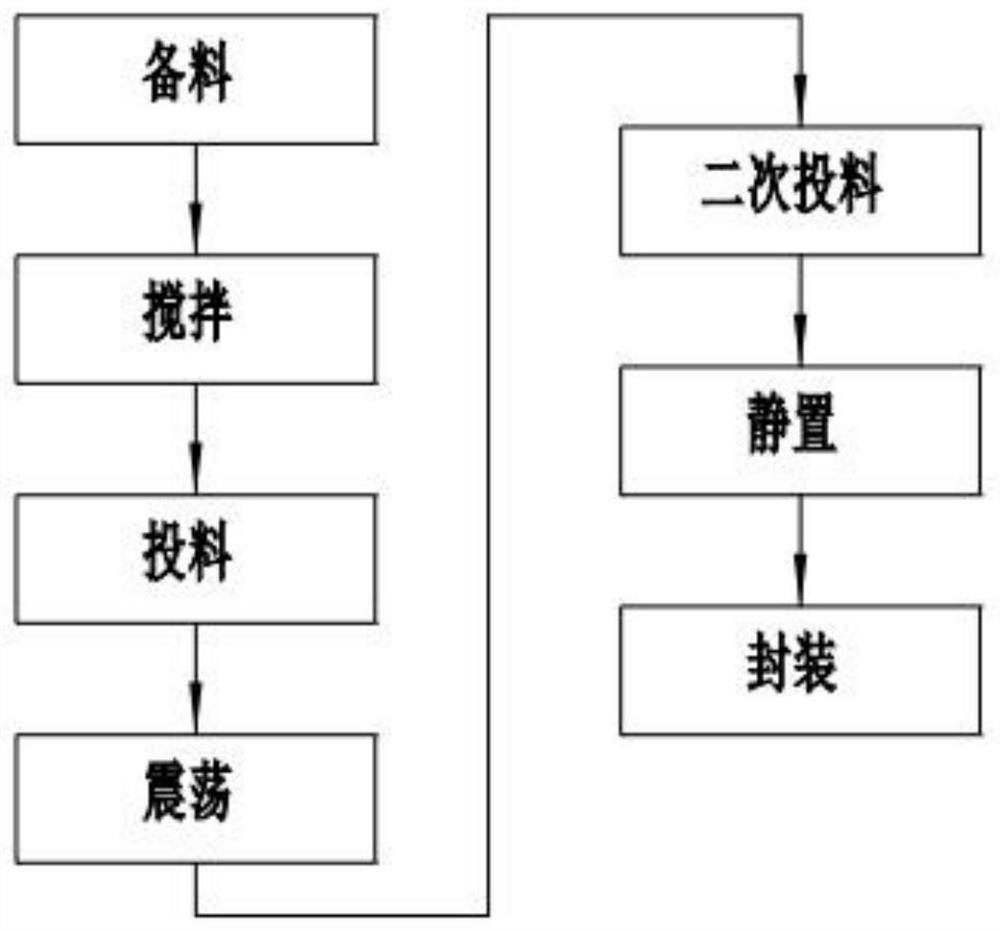

[0035] A method for preparing a water-soluble corrosion inhibitor for a hydrogenation unit, comprising the following steps: in parts by volume;

[0036] S1. Preparation of materials: 20 parts of palmitic acid, 40 parts of polyethylene glycol compounds, 30 parts of cyanate compounds, and 20 parts of ethylenediamine are dissolved in an organic solvent, and 5 parts of catalyst are added to prepare a mixed raw material;

[0037] S2. Stirring: the mixed raw materials in S1 are continuously stirred for 5 hours in a mixing tank to make a preliminary mixed material;

[0038] S3. Feeding: add 30% water-soluble imidazoline to the preliminary mixture in S2, and use a stirring tank to continuously stir for 0.5 to 2 hours to prepare a semi-finished mixture;

[0039] S4. Oscillation: Use a vibrator to vibrate the semi-finished mixture in S3 at high frequency for 1 to 2 hours to discharge the air bubbles in the mixture;

[0040] S5. Secondary feeding: Add 30 parts of petroleum ether to the ...

Embodiment 2

[0053] A method for preparing a water-soluble corrosion inhibitor for a hydrogenation unit, comprising the following steps: in parts by volume;

[0054] S1. Preparation of materials: 20 parts of palmitic acid, 40 parts of polyethylene glycol compounds, 40 parts of cyanate compounds, and 20 parts of ethylenediamine are dissolved in an organic solvent, and 5 parts of catalyst are added to prepare a mixed raw material;

[0055] S2. Stirring: the mixed raw materials in S1 are continuously stirred for 5 hours in a mixing tank to make a preliminary mixed material;

[0056]S3. Feeding: add 30% water-soluble imidazoline to the preliminary mixture in S2, and use a stirring tank to continuously stir for 0.5 to 2 hours to prepare a semi-finished mixture;

[0057] S4. Oscillation: Use a vibrator to vibrate the semi-finished mixture in S3 at high frequency for 1 to 2 hours to discharge the air bubbles in the mixture;

[0058] S5. Secondary feeding: Add 30 parts of petroleum ether to the s...

Embodiment 3

[0071] A method for preparing a water-soluble corrosion inhibitor for a hydrogenation unit, comprising the following steps: in parts by volume;

[0072] S1. Preparation of materials: 20 parts of palmitic acid, 40 parts of polyethylene glycol compounds, 50 parts of cyanate compounds, and 20 parts of ethylenediamine are dissolved in an organic solvent, and 5 parts of catalyst are added to prepare a mixed raw material;

[0073] S2. Stirring: the mixed raw materials in S1 are continuously stirred for 5 hours in a mixing tank to make a preliminary mixed material;

[0074] S3. Feeding: add 30% water-soluble imidazoline to the preliminary mixture in S2, and use a stirring tank to continuously stir for 0.5 to 2 hours to prepare a semi-finished mixture;

[0075] S4. Oscillation: Use a vibrator to vibrate the semi-finished mixture in S3 at high frequency for 1 to 2 hours to discharge the air bubbles in the mixture;

[0076] S5. Secondary feeding: Add 30 parts of petroleum ether to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com