High-reflection photovoltaic module packaging adhesive film with three-layer structure

A photovoltaic module encapsulation, three-layer structure technology, applied in photovoltaic power generation, adhesives, electrical components, etc., can solve the problems of easy delamination of the film, cracked cells, affecting the appearance, etc., to achieve good anti-PID effect and power improvement. Excellent, high reflectivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] above as figure 1 The preparation method of the high-reflection photovoltaic module encapsulation film of the shown three-layer structure comprises the following steps:

[0034] (1) After fully mixing the second main body resin and the inorganic filler, co-extrude and granulate through a twin-screw extruder to make a masterbatch;

[0035] (2) Put the masterbatch and the second main resin into the mixer and mix them thoroughly for 5 to 10 minutes, put them into the extrusion hopper, cast them through a single screw or twin screws, and then squeeze them through rubber rollers with a structure on the surface. After cooling, the structural reflective layer is obtained;

[0036] (3) Add the first main body resin, antioxidant and UV stabilizer into the mixer and mix thoroughly for 5 to 15 minutes, and then extrude and cast on the upper surface of the structural reflective layer through a single screw to obtain a transition layer / Structural reflective layer;

[0037] (4) A...

Embodiment 1

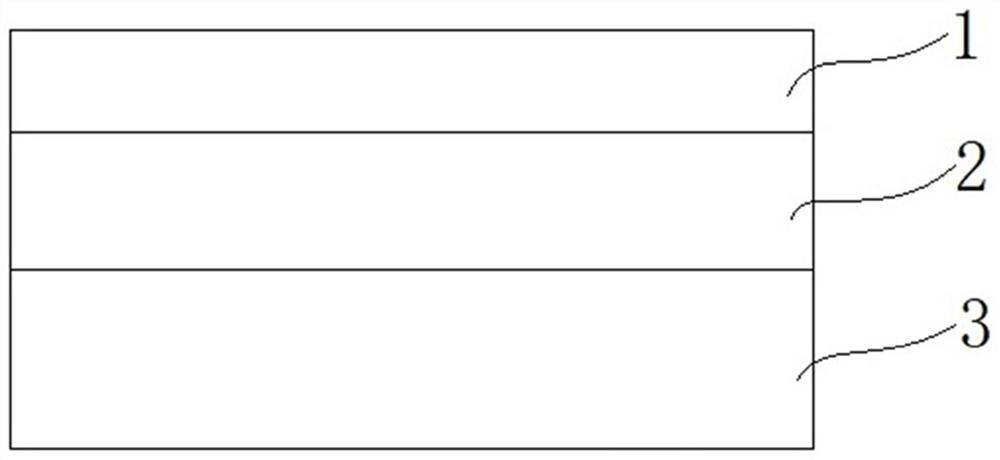

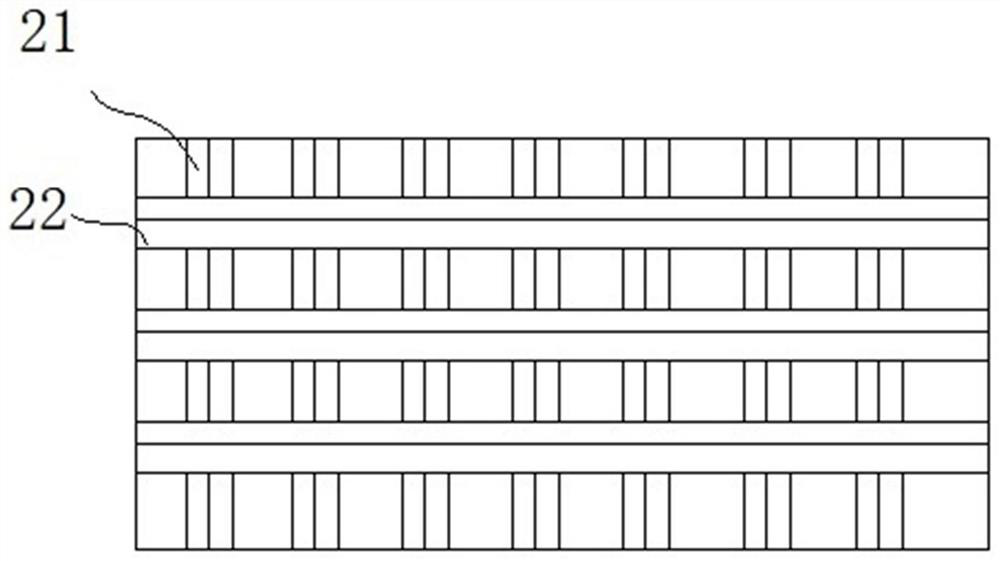

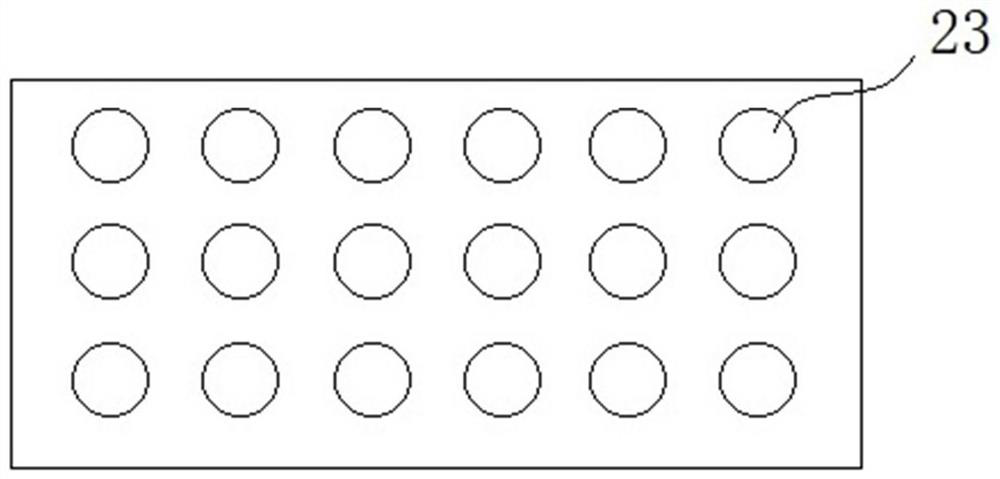

[0041] A high-reflection photovoltaic module encapsulation adhesive film with a three-layer structure according to the present invention includes a transition layer 1 , a structural reflection layer 2 , and an encapsulation layer 3 sequentially arranged from top to bottom. The thickness of the transition layer 1 is 75 μm, and the material of the transition layer 1 is the first host resin, antioxidant and UV stabilizer, and the mass ratio of the first host resin, antioxidant and UV stabilizer is 87:5:8. The first main resin is EVA resin, wherein the molar content of vinyl acetate is 15%, the melt flow rate of the first main resin is 0.5g / 10min, and the antioxidant is β-(3,5-di-tert-butyl-4- Octadecyl hydroxyphenyl)propionate and tris(4-nonylphenol)phosphite are mixed, and the UV stabilizer is 2,4-dihydroxybenzophenone. The upper surface of the structural reflection layer 2 is provided with a plurality of parallel first prism structures 21 and a plurality of parallel second pris...

Embodiment 2

[0043] A high-reflection photovoltaic module encapsulation adhesive film with a three-layer structure according to the present invention includes a transition layer 1 , a structural reflection layer 2 , and an encapsulation layer 3 sequentially arranged from top to bottom. The thickness of the transition layer 1 is 100 μm, and the material of the transition layer 1 is the first host resin, antioxidant and UV stabilizer, and the mass ratio of the first host resin, antioxidant and UV stabilizer is 88:4:8. The first main body resin is EVA resin, wherein vinyl acetate molar content is 20%, the melt flow rate of the first main body resin is 2.5g / 10min, antioxidant is three (4-nonylphenol) phosphite, phosphorous acid A mixture of at least two of tris(2,4-di-tert-butylphenyl) esters, the UV stabilizer is succinic acid polymerized with 4-hydroxy-2,2,6,6-tetramethyl-1-pyridine ethanol things. The upper surface of the structural reflection layer 2 is provided with a plurality of parall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com