White-carbon-black-free solid silicone rubber for high-hardness rubber roller, and preparation method of white-carbon-black-free solid silicone rubber

A technology of white carbon black and high hardness, which is applied in the field of solid silicone rubber for high hardness rubber rollers and its preparation, and can solve problems affecting the normal production of plastic films and the peeling properties of films and rubber rollers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

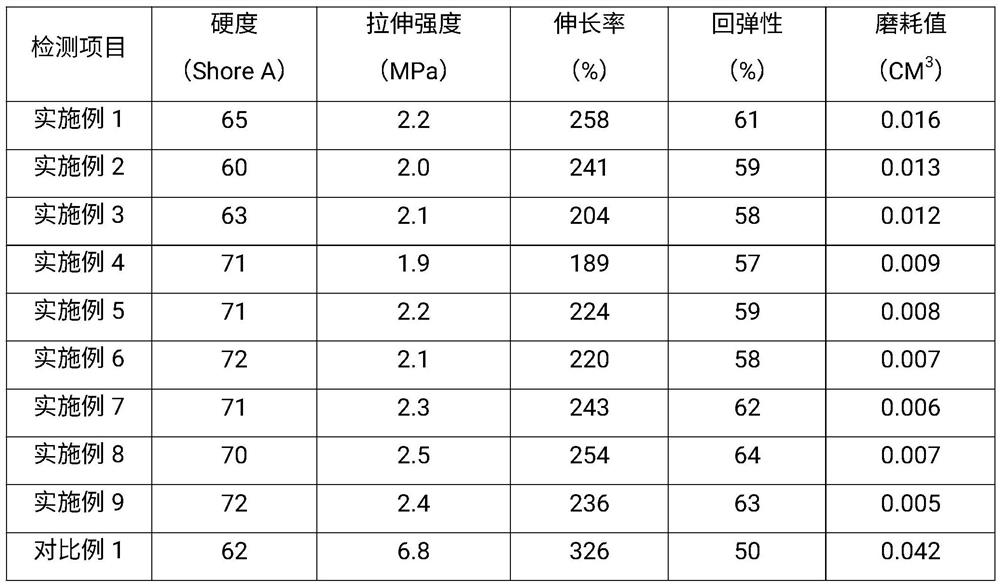

Examples

Embodiment 1

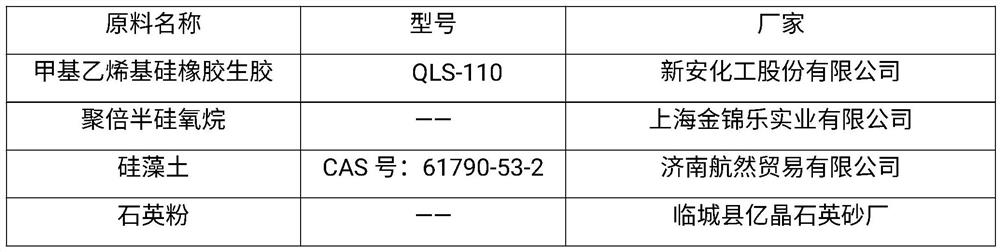

[0057] A solid silicone rubber for high-hardness rubber rollers without silica, made of the following raw materials by weight:

[0058] Raw methyl vinyl silicone rubber: 1000kg;

[0059] Polysilsesquioxane: 300kg;

[0060] Diatomite: 400kg;

[0061] Silane coupling agent: 1kg;

[0062] Among them, the molar mass of methyl vinyl silicone rubber raw rubber is 40W, the vinyl content of methyl vinyl silicone rubber raw rubber is 0.03%-1%, and the average particle size of polysilsesquioxane is 0.1-100um , The silane coupling agent is KH792.

[0063] Above-mentioned a kind of preparation method of solid silicon rubber for high hardness rubber roller not containing white carbon black comprises the following steps:

[0064] S1. Mix methyl vinyl silicone rubber raw rubber, polysilsesquioxane and silane coupling agent into a mass in a kneader, and control the temperature system to 100°C;

[0065] S2, heat up to 160°C in the kneader, heat treatment for 2h;

[0066] S3. Cool the pro...

Embodiment 2

[0068] A solid silicone rubber for high-hardness rubber rollers without silica, made of the following raw materials by weight:

[0069] Raw methyl vinyl silicone rubber: 1000kg;

[0070] Polysilsesquioxane: 500kg;

[0071] Diatomite: 200kg;

[0072] Silane coupling agent: 5kg;

[0073] Among them, the molar mass of methyl vinyl silicone rubber raw rubber is 50W, the vinyl content of methyl vinyl silicone rubber raw rubber is 0.03%-1%, and the average particle size of polysilsesquioxane is 0.1-100um , The silane coupling agent is KH560.

[0074] Above-mentioned a kind of preparation method of solid silicon rubber for high hardness rubber roller not containing white carbon black comprises the following steps:

[0075] S1. Mix methyl vinyl silicone rubber raw rubber, polysilsesquioxane and silane coupling agent into a mass in a kneader, and control the temperature system to 90°C;

[0076] S2, heat up to 155° C. in a kneader, and heat-treat for 3 hours;

[0077] S3. Cool the...

Embodiment 3

[0079] A solid silicone rubber for high-hardness rubber rollers without silica, made of the following raw materials by weight:

[0080] Raw methyl vinyl silicone rubber: 1000kg;

[0081] Polysilsesquioxane: 600kg;

[0082] Diatomite: 200kg;

[0083] Silane coupling agent: 10kg;

[0084] Among them, the molar mass of methyl vinyl silicone rubber raw rubber is 30W, the vinyl content of methyl vinyl silicone rubber raw rubber is 0.03%-1%, and the average particle size of polysilsesquioxane is 0.1-100um , the silane coupling agent is A-172.

[0085] Above-mentioned a kind of preparation method of solid silicon rubber for high hardness rubber roller not containing white carbon black comprises the following steps:

[0086] S1. Mix methyl vinyl silicone rubber raw rubber, polysilsesquioxane and A-172 into a mass in a kneader, and control the temperature system to 100°C;

[0087] S2, heat up to 160°C in the kneader, heat treatment for 2h;

[0088] S3. Cool the product of step S2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com