A kind of gelatin/gellan gum/hydroxyapatite composite hydrogel and preparation method thereof

A composite hydrogel and hydroxyapatite technology, which can be used in pharmaceutical formulations, prostheses, drug delivery, etc., can solve the problems of unfavorable tissue cell attachment and proliferation, difficulty in complete degradation, and large cell toxicity, and achieve a balance of reduction Improvement of swelling rate and compressive mechanical strength, effect of improving compressive mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

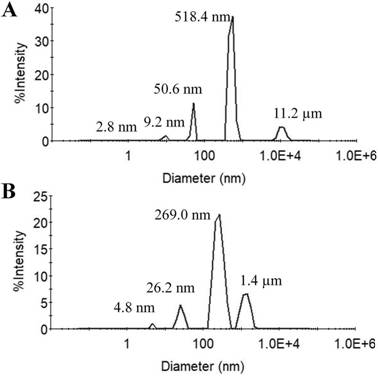

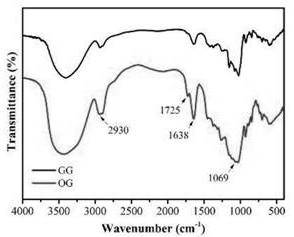

[0056] Example 1 Preparation and characterization of oxidized gellan gum

[0057] 1. Preparation method of oxidized gellan gum

[0058] The preparation process of oxidized gellan gum (OG) is as follows:

[0059] (1) Weigh a certain amount of low-acyl gellan gum (GG), disperse it in 200 mL of distilled water at 90 °C, stir for 30 min, and obtain a uniform GG solution, and gradually cool down to 40 °C.

[0060] (2) Add a certain amount of NaIO to the GG solution 4 , Under the condition of avoiding light, control the oxidation temperature and oxidation time, and stir vigorously to obtain the mixed solution of oxidized gellan gum.

[0061] (3) Pour the oxidized gellan gum mixture into a dialysis bag with a molecular weight of 8-14kDa, and use distilled water for 5 days at room temperature to remove residual NaIO 4 With the reaction by-products, the mixed solution after dialysis is suction filtered, the solution obtained by suction filtration is pre-frozen at -20 ℃ for 12 hours,...

Embodiment 2

[0079] Example 2 Preparation and Characterization of Aminated Hydroxyapatite

[0080] 1. Preparation of Aminated Hydroxyapatite

[0081] The preparation process of aminated hydroxyapatite includes the synthesis of hydroxyapatite (Hap) and the process of preparing aminated hydroxyapatite (mHap) from hydroxyapatite. The specific process is as follows:

[0082] (1) Synthesis of hydroxyapatite

[0083] (1) Dissolve calcium nitrate and diammonium hydrogen phosphate in distilled water to obtain 1.2M Ca respectively 2+ Solution, 0.72M HPO 4 2- solution.

[0084] (2) At 40°C, the Ca 2+ The solution was slowly dripped into HPO according to the volume ratio of 1:1 4 2- In the solution, at the same time, the pH of the mixture was stabilized at 10.5 with ammonia water, and the reaction was continued for 2 h.

[0085] (3) The reaction solution was allowed to stand at 50°C for 12 hours, and the white precipitate was collected by centrifugation. The precipitate was washed alternately...

Embodiment 3

[0109] Example 3 Preparation and characterization of gelatin / oxidized gellan hydrogel

[0110] 1. Preparation method of gelatin / oxidized gellan hydrogel

[0111] The preparation process of gelatin / oxidized gellan gum (Gel-OG) hydrogel is as follows:

[0112] (1) Dissolve 1 g of Gel in distilled water at 50 °C to obtain a 20 wt% Gel solution.

[0113] (2) Weigh a certain amount of OG and dissolve it in distilled water at 40°C to obtain OG solutions of 1wt%, 1.5wt%, 2wt%, 2.5wt% and 3wt% respectively; wherein, oxidized gellan gum (OG) Prepared by the optimized conditions of Example 1, namely GG and NaIO in the preparation process of OG 4 The mass ratio was 1:0.9, the oxidation temperature was 40°C, and the oxidation time was 8h.

[0114] (3) OG solution and Gel solution with different concentrations were mixed at 40°C in a mass ratio of 1:1.

[0115](4) Pour the mixture into five glass test tubes, each with an inner diameter of 13 mm and a depth of 100 mm, sealed and placed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| compressive stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com