A kind of high-strength water-resistant phosphogypsum composite cementitious material and its preparation method

A technology of composite cementitious materials and phosphogypsum, which is applied in the field of building materials, can solve the problems of difficulty in preparing high-strength water-resistant gypsum products, high saturated water absorption rate, and low softening coefficient, and achieve environmental protection of high-strength water-resistant phosphogypsum composite cementitious materials , Good construction, simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

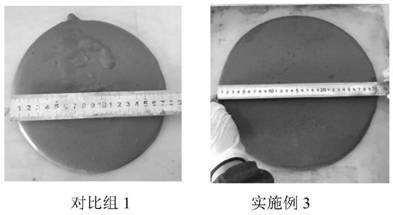

Image

Examples

preparation example Construction

[0048] The preparation method of common phosphogypsum comprises the steps:

[0049] (1) Add water to the gypsum powder, stir for 2 minutes to obtain gypsum slurry;

[0050] (2) Pour the gypsum slurry into the mold, remove the mold after hardening, and dry and cure the gypsum specimen at 45°C for 24 hours to obtain the ordinary phosphogypsum specimen.

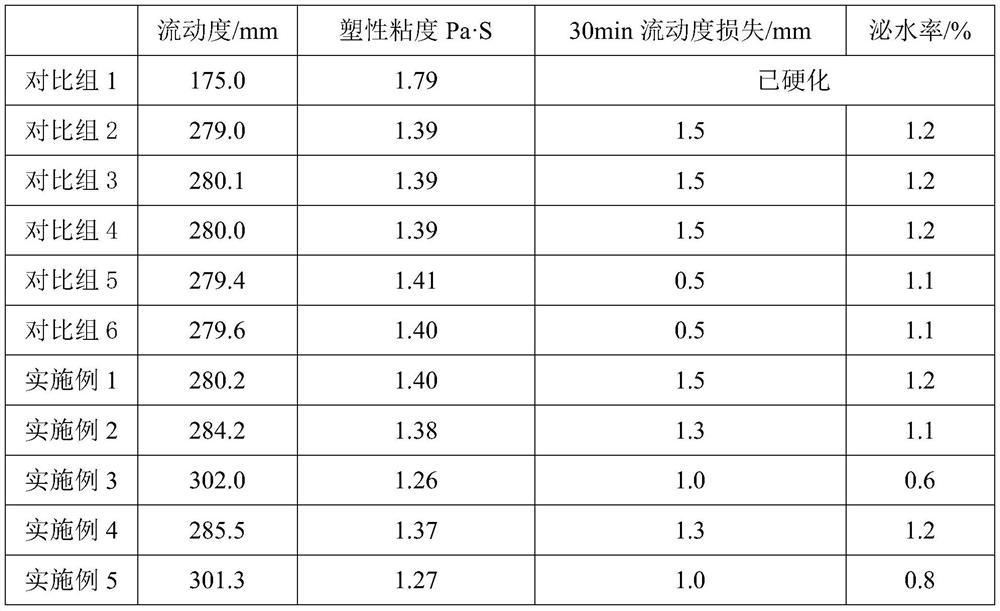

[0051] Comparison group 2

[0052] The comparison group 2 is composed of the following components in parts by weight: 2.5 parts of waterproofing agent, 5 parts of cement, 5 parts of sulfur-fixing ash, 1 part of zeolite powder, 100 parts of β-type phosphorus building gypsum powder, 0.2 parts of calcium oxide, rheological agent 0.5 parts, 37 parts of water.

[0053] The formula of waterproofing agent is 1 part of silicone polymer, 1.5 parts of silicon acrylic emulsion, 0.15 parts of sodium lauryl sulfate; the formula of rheological agent is 9 parts of polycarboxylate water reducing agent, 2 parts 1 part, 2 parts of protein reta...

Embodiment 1

[0067] A high-strength water-resistant phosphogypsum composite cementitious material, which consists of the following components in parts by weight: 2.5 parts of waterproofing agent, 5 parts of cement, 5 parts of sulfur-fixing ash, 5 parts of coal gasification slag, 1 part of zeolite powder, and β-type 100 parts of phosphorus building gypsum powder, 0.2 parts of calcium oxide, 0.5 parts of rheological agent, and 37 parts of water.

[0068] The formula of waterproofing agent is 1 part of silicone polymer, 1.5 parts of silicon acrylic emulsion, 0.15 parts of sodium lauryl sulfate; the formula of rheological agent is 9 parts of polycarboxylate water reducing agent, 2 parts 1 part, 2 parts of protein retarder, 0.1 part of borax.

Embodiment 2

[0070]A high-strength and water-resistant phosphogypsum composite cementitious material, which consists of the following components in parts by weight: 1.5 parts of waterproofing agent, 6 parts of cement, 6 parts of sulfur-fixing ash, 5 parts of coal gasification slag, 0.5 part of zeolite powder, calcium oxide 1 part, 100 parts of phosphorus building gypsum powder, 1 part of rheological agent, 35 parts of water.

[0071] The formula of waterproofing agent is 0.2 parts of silicone polymer, 0.5 parts of emulsion, 0.01 part of sodium lauryl sulfate; the formula of rheological agent is 8 parts of polycarboxylate water reducing agent, 1 part of melamine water reducing 1 part of protein retarder, 0.2 part of borax.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com