Hard coating film

A technology of hard coating film and top coating, applied in the direction of coating, polyester coating, etc., can solve the problems of insufficient flexibility, curling, inability to apply flexible displays, etc., to achieve excellent hardness properties, improve flexibility and curling properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

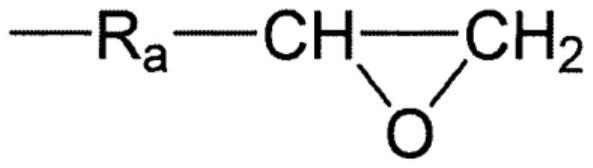

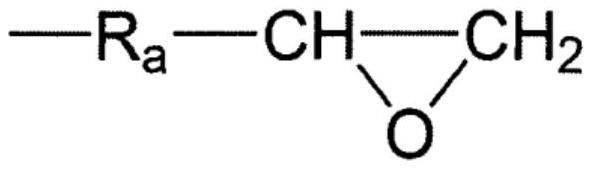

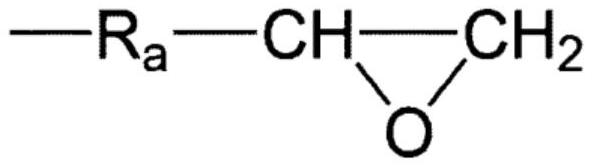

Method used

Image

Examples

preparation example 1 to 8

[0145] Each resin composition was prepared by mixing the components described in Table 1 below. In this regard, based on 100 parts by weight of epoxy polysiloxane, 3 parts by weight of iodine-based Compound (Omnicat 250 TM , a product of BASF), 10 parts by weight of toluene as a solvent, and 0.2 parts by weight of a fluorine-based compound (RS-55 TM , a product of MEGAFACE).

[0146] [Table 1]

[0147]

[0148] In Table 1, the content unit "% by weight" is a value expressed as a percentage by weight of the corresponding component based on the total weight of the resin composition including epoxypolysiloxane, reactive monomer, and elastomer.

Embodiment 1 to 8

[0150] Each hard coat film in which a top coat layer and an undercoat layer were formed on top and bottom surfaces of a substrate, respectively, was produced by using each resin composition having the composition described in Table 2 below.

[0151] In detail, the second resin composition for forming an undercoat layer described in Table 2 below was applied to one surface of a PET substrate having a size of 15 cm×20 cm and a thickness of 50 μm, and then was irradiated by UV using a UV lamp ( Light dose: 400mJ / cm 2 ) for photocuring to form an undercoat layer. The first resin composition for forming a top coat layer described in Table 2 below was applied to the other surface opposite to the surface of the PET substrate on which the undercoat layer was formed, and then irradiated by UV using a UV lamp (light Dose: 400mJ / cm 2 ) was photocured to produce a hard coat film (thickness of top coat: 80 μm, thickness of undercoat: 100 μm, total thickness: 230 μm).

experiment example

[0159] The physical properties of the hard coat films produced in Examples 1 to 7 and Comparative Examples 1 and 2 were measured by the following methods, and the results are shown in Table 3 below.

[0160] 1) Pencil hardness (top coat)

[0161] Using a pencil hardness tester, according to standard JIS K5400, under a load of 1.0 kg, the top coat layer of each hard coating film produced in Examples 1 to 7 and Comparative Examples 1 and 2 was double-rubbed five times to determine whether The hardness at which scratches appear.

[0162] 2) Inward bending characteristics

[0163] While changing the inner radius of curvature (R) of the folded portion, each of the hard coating films produced in Examples and Comparative Examples was folded and unfolded 200,000 times so that the surface where the coating was formed was folded inward, in other words, when only the When the coating is formed on one surface of the substrate, the surface on which the coating is formed is folded inward,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com