Device and method for liquid injection and liquid replacement of cylindrical battery

A cylindrical battery, battery technology, applied in battery pack parts, circuits, electrical components, etc., can solve the problems of liquid infiltration and prolonged discharge time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The present invention will be further described through embodiments below in conjunction with the accompanying drawings.

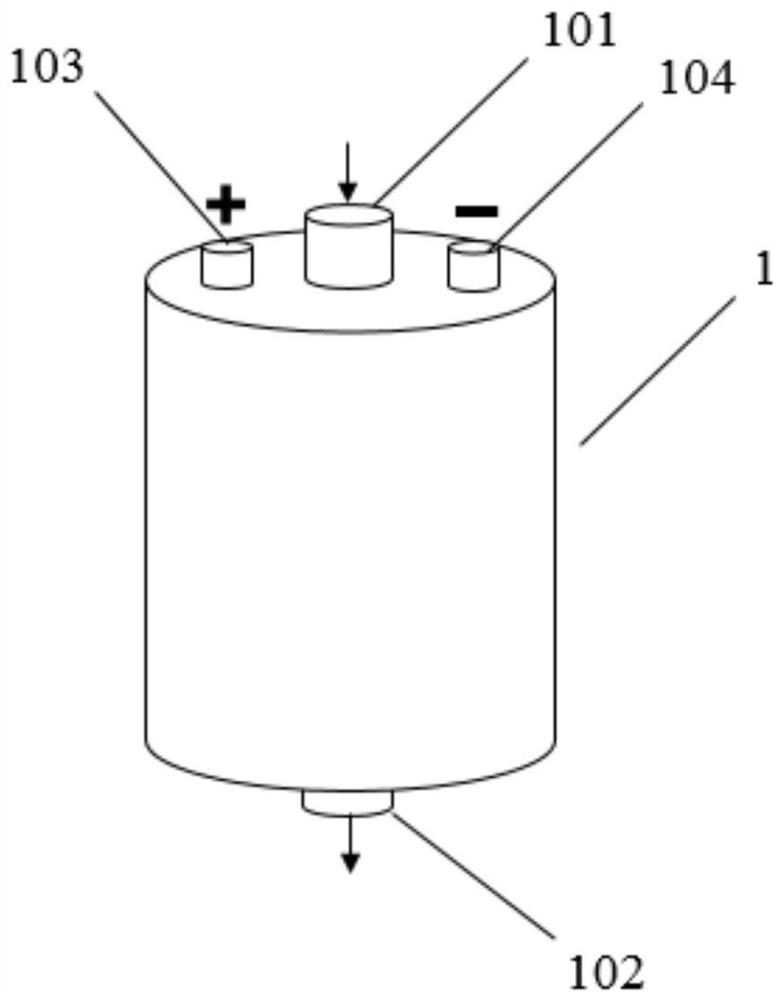

[0071] figure 1 is a schematic diagram of a cylindrical battery according to an embodiment. Such as figure 1 As shown, the injection port 101 and the discharge port 102 of the cylindrical battery 1 are respectively arranged on the two opposite end surfaces of the battery case, and the injection port 101 and the discharge port 102 are both arranged at the center of the end surface, and the fluid injected into the cylindrical battery from the injection port 101 The winding part of the electric core can be entered through the flow opening on the side wall of the electric core. The positive pole 103 and the negative pole 104 are located on the same end surface of the battery case as the injection port 101, and the positive pole 103 and the negative pole 104 are deviated from the center of the end surface.

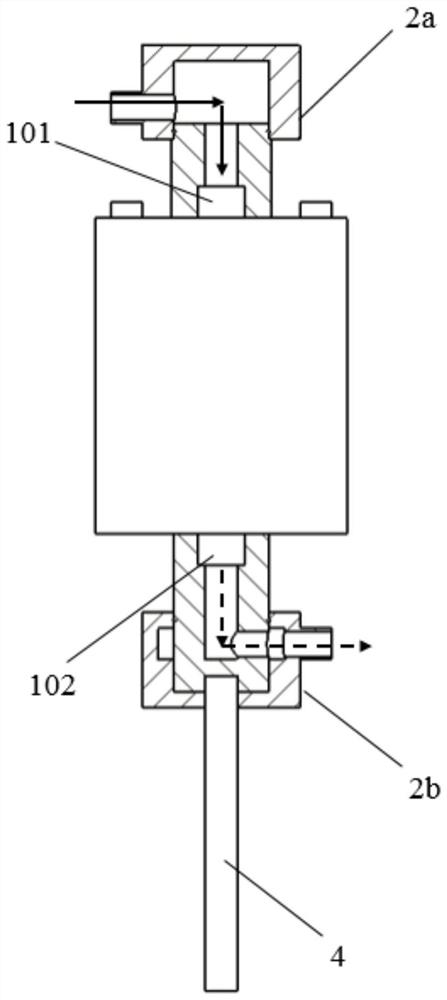

[0072] Figure 2(a)-2(e) It is a schematic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com