Device for producing collimator by general optical semi-automatic reflection method and production method thereof

A general-purpose optical and collimator technology, applied in the field of optical fiber communication, to achieve the effect of convenient operation and saving production space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

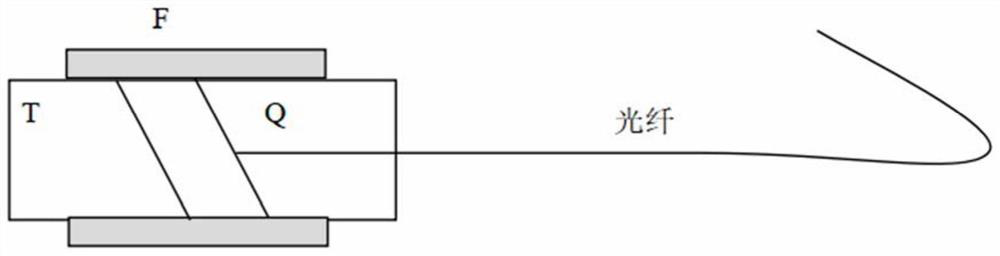

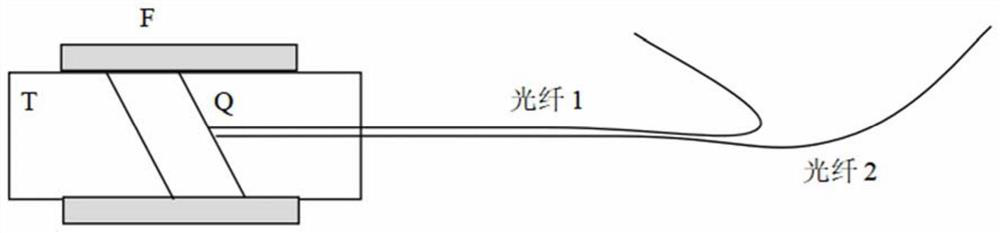

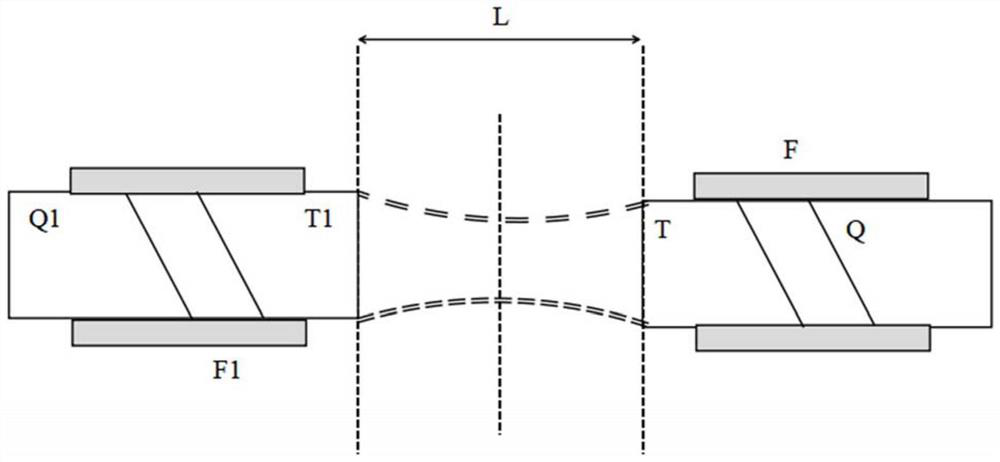

[0049] A kind of general optical semi-automatic reflection method produces collimator device and production method thereof, refer to Figure 7 , is a schematic structural diagram of the automatic adjustment of the embodiment of the present invention.

[0050] A collimator device produced by a general optical semi-automatic reflective method is characterized in that it includes an upper unit, a lower unit, a left-handed adjustment frame group, a side collimator external sealing glass tube fixing frame, and a right-hand adjustment frame group; The left-hand adjustment frame group includes an electric horizontal inclination adjustment frame 1, an electric vertical inclination adjustment frame 2, a mirror fixing frame 53 and a mirror 4 fixed at its end; on the frame 1; the side collimator outer sealing glass tube fixing frame includes a side clip support frame 62 and the outer sealing glass tube clamping clamp 71 fixedly arranged on it; the outer sealing glass tube clamping clamp ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com