Power electronic integrated module layered cold plate performance test platform and test method

An integrated module and power electronics technology, applied in the field of power electronics integrated module layered cold plate performance test platform, can solve the problems of different sizes, high possibility of interference, different layout of entrances and exits, etc. Difficulty of experimental operation and avoid the effect of construction work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

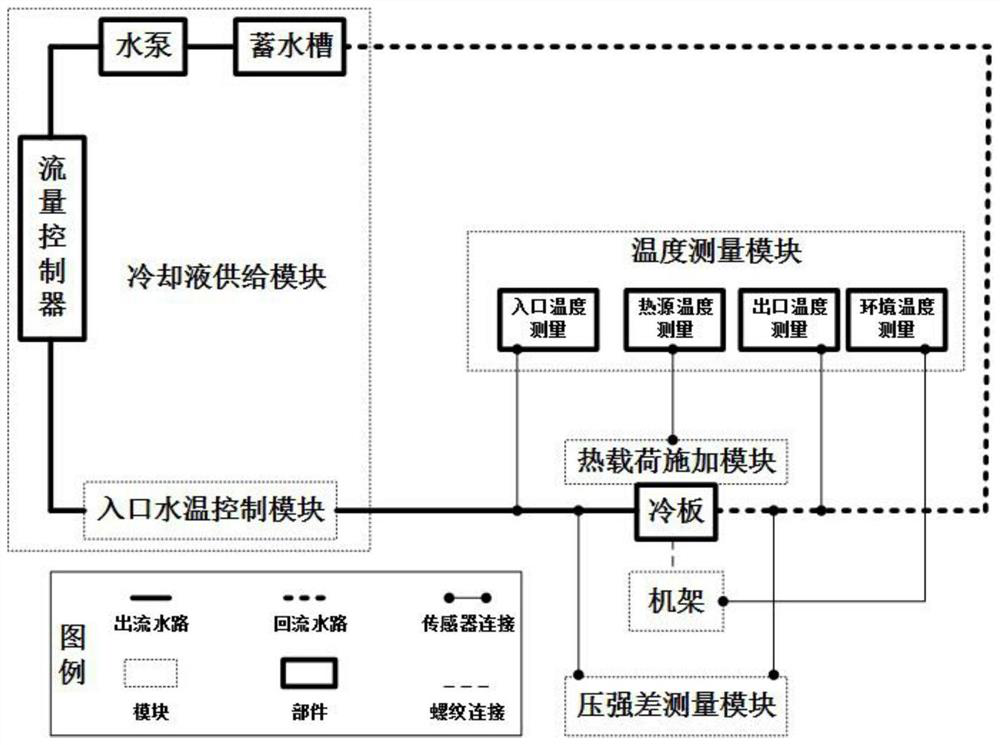

[0036] Such as figure 1As shown, a performance test platform for a layered cold plate of a power electronic integrated module includes a frame on which a cold plate is threaded, the inlet of the cold plate is connected to the outlet of the inlet water temperature control module, and the inlet of the inlet water temperature control module It is connected to the outlet of the flow controller, the inlet of the flow controller is connected to the outlet of the water pump, the inlet of the water pump is connected to the outlet of the water storage tank, the water storage tank, the water pump, the flow controller, and the inlet water temperature control module constitute the coolant supply module; the cold plate The outlet of the tank is connected to the return port of the water storage tank;

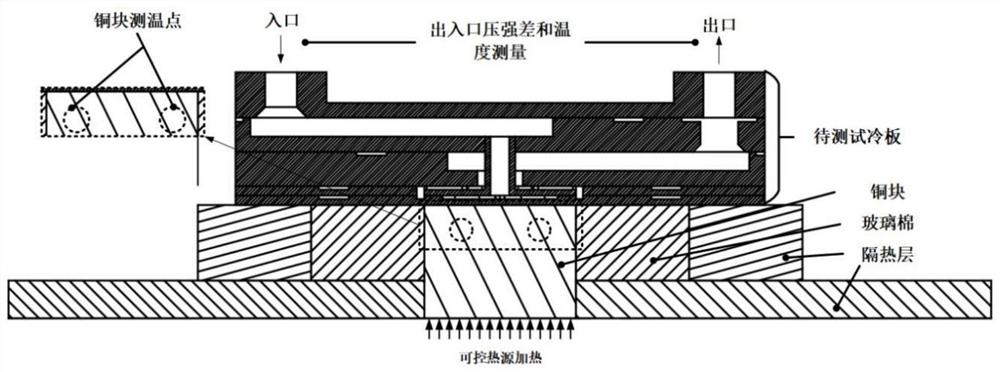

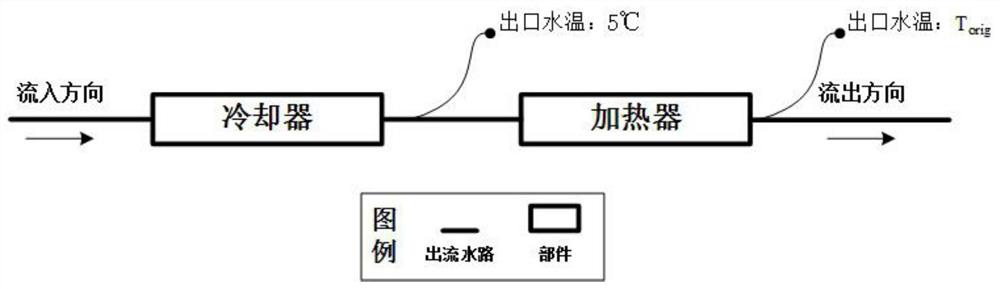

[0037] The cold plate is provided with a thermal load applicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com