Method for quickly preparing nano thermal insulation material by supercritical drying

A nano-insulation material and supercritical drying technology, which is applied in the processing of textile materials, equipment configuration for processing textile materials, spraying/spraying of textile materials, etc., can solve the problem of increasing the production cost of nano-insulation materials, low solution recovery rate, Long drying time and other issues, to avoid the volatilization of organic solvents and personnel contact with volatiles, the process is simple, and the effect of saving equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

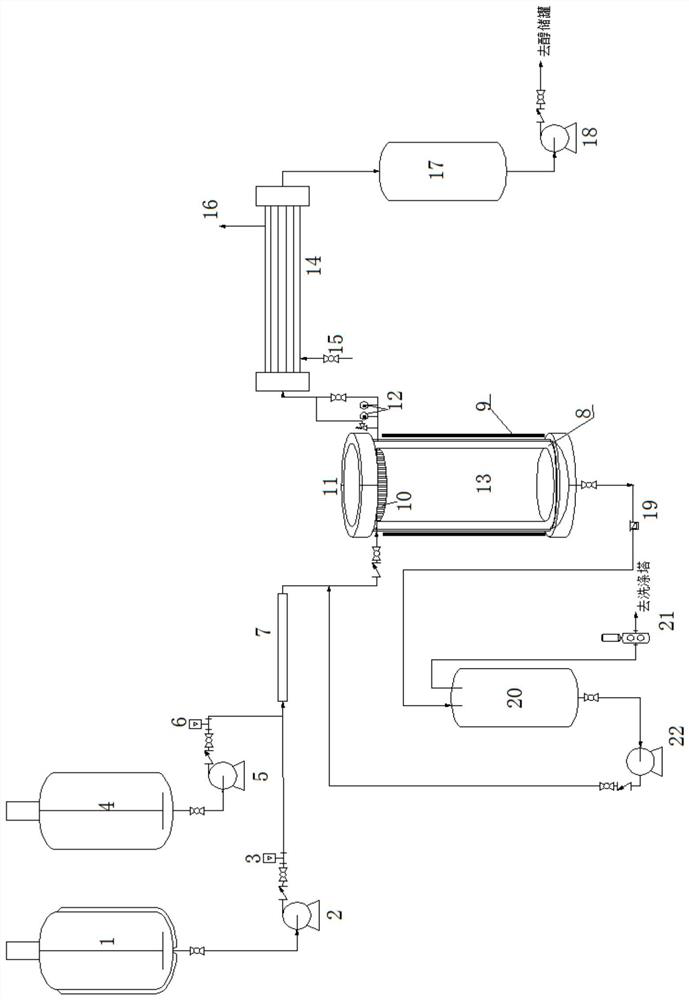

[0033] See figure 1 , figure 2 , The present invention provides a method for quickly preparing nano thermal insulation materials by supercritical drying. The entire process flow from front to back includes hydrolysis solution preparation, lye configuration, gel solution mixing, spray impregnation, cycle impregnation, and heating Gel, heating and drying, complete drying.

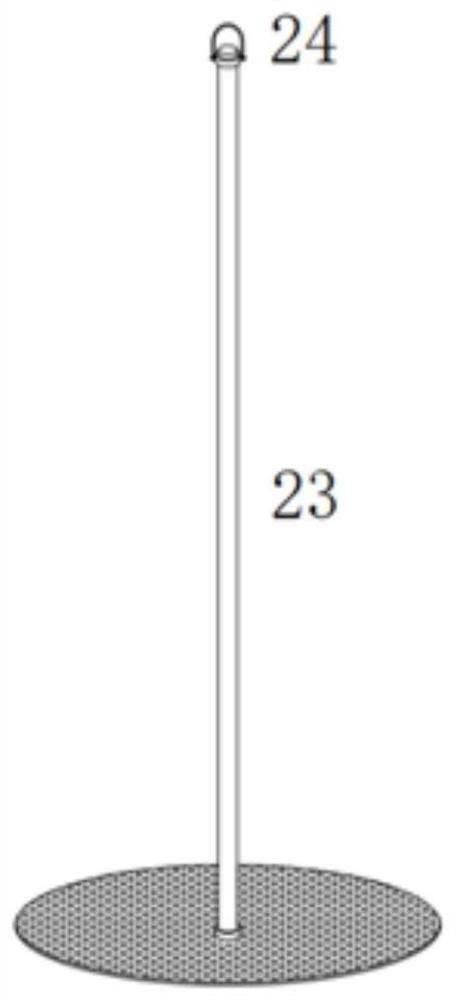

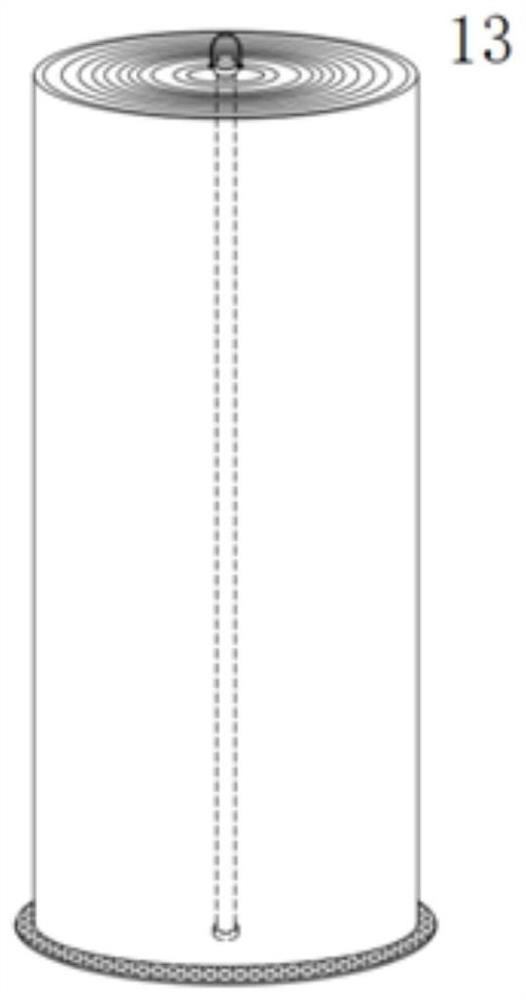

[0034] The fiber felt web 13 fixed on the web loading and unloading tray 23 is hoisted and put into the supercritical drying kettle 8, the cloth pipe 10 is connected with the feed pipe of the drying kettle using a quick-connect clamp, and the drying kettle lid 11 is covered.

[0035] Ethyl orthosilicate and methyl triethoxy silicon are mixed at a molar ratio of 1:1, and then used as a silicone source, and ethanol, water, and oxalic acid are added to the hydrolysate preparation tank 1 in a molar ratio of 1:20:4:0.02. Stir and raise the temperature to 50°C for 4 hours. After being pumped by the first delivery pump ...

Embodiment 2

[0046] The difference from Example 1 is that the mixed silicon source is replaced with methyl orthosilicate and methyl trimethoxy silicon mixed in a ratio of 1:1, and the catalyst acid is replaced with a mixed acid with a molar ratio of hydrochloric acid and hydrofluoric acid of 1:2. After replacing ethanol with methanol, mix according to the molar ratio of silicon source: alcohol: water: acid=1:18:4.5:0.02 to form a hydrolysis solution. The hydrolysis temperature is between 40 and 55°C, and other conditions remain basically unchanged. Supercritical drying is changed to methanol supercritical drying. The produced aerogel has better elasticity and lower thermal conductivity.

Embodiment 3

[0048] The difference from the first embodiment is that the fiber felt and the 5mm thick spacer (PP material hexagonal mesh) are rolled together, so that there is a larger gap between the fiber felt layer and the layer, and the supercritical temperature The holding time is shortened to 30min, which speeds up the drying speed. After drying, it is necessary to rewind the nano heat insulation material and recycle the spacer. The prepared nano heat insulation material has a stable surface structure and good appearance quality. At the same time, the method is also suitable for changing supercritical alcohol drying to supercritical carbon dioxide drying to prepare nano thermal insulation materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com