Preparation method of prostaglandin analogue

A prostaglandin and analogue technology, which is applied in the field of preparation of prostaglandin analogues, can solve the problems of low yield, fewer prostaglandin synthesis methods, and harsh conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

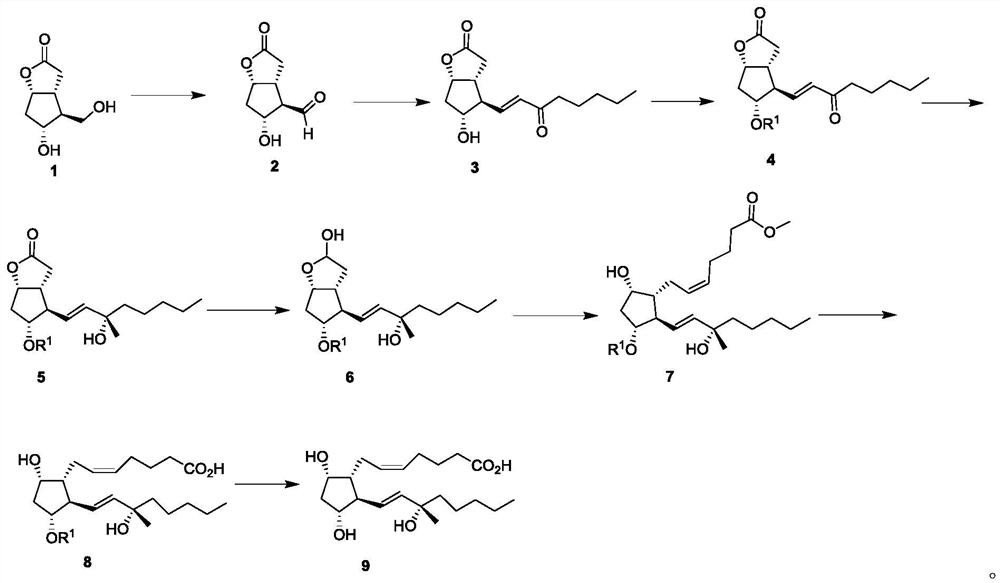

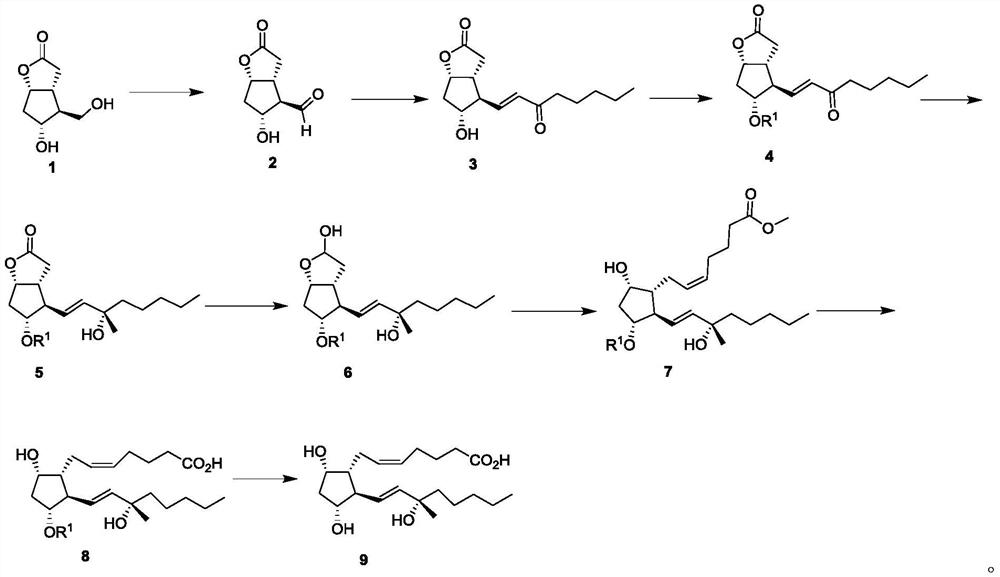

Method used

Image

Examples

Embodiment 1

[0091] (1) Synthesis of compound 2

[0092]

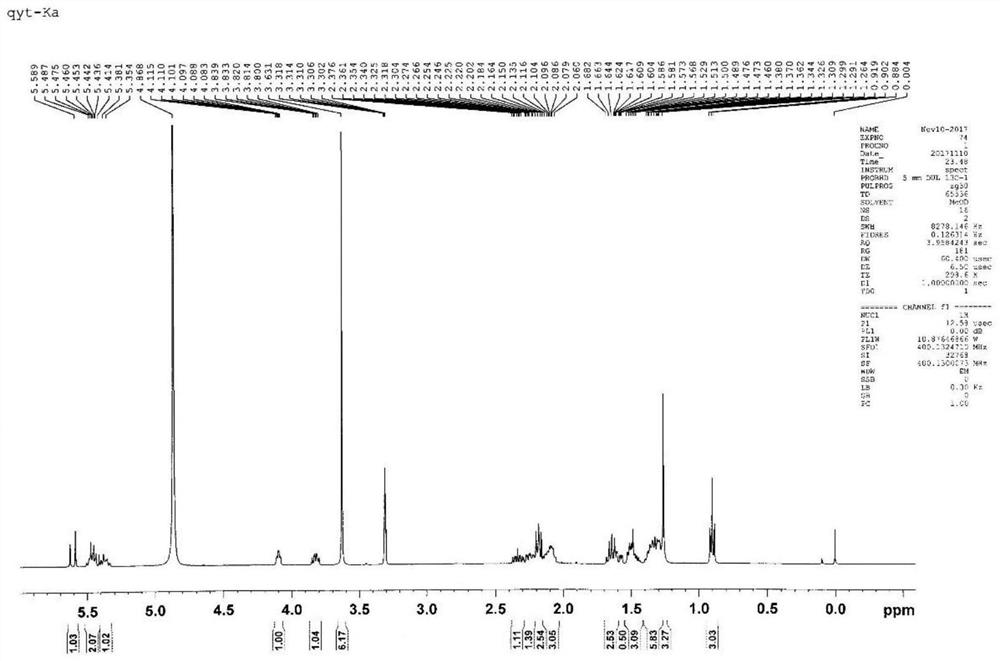

[0093] Compound 1 (5.7g, 30mmol) and TEMPO (470mg, 3mmol) were dissolved in 500mL DMA / DCM (v / v=1:300), at room temperature, PhI(OAc) 2 (10.6g, 33mmol) was slowly added to the above solution. The reaction solution was stirred at room temperature for 6 h. The solvent was distilled off under reduced pressure to obtain a black oily crude product without any residual acetic acid, which was directly put into the next reaction without purification. 1 H NMR (400MHz, Chloroform-d) δ9.44 (d, J = 6.2Hz, 1H), 4.82 (dt, J = 5.1, 4.2Hz, 1H), 3.94 (qd, J = 5.6, 4.6Hz, 1H) ,3.61(d,J=5.3Hz,1H),2.67(q,J=5.9Hz,1H),2.65–2.50(m,3H),2.16(dt,J=14.5,5.4Hz,1H),1.83– 1.75(m,1H).

[0094] (2) Synthesis of compound 3

[0095]

[0096] 0°C, under the protection of nitrogen, the solution of β-dimethoxyheptyl carbonyl phosphate (10g, 45mmol) in THF (50mL) was slowly added dropwise to the suspension of NaH (1.8g, 45mmol) in anhydrous THF (100mL) middl...

Embodiment 2

[0119] (1) Synthesis of compound 2

[0120]

[0121] A solution of DMSO (3ml, 42.2mmol) in DCM (20mL) was added dropwise to a solution of oxalyl chloride (1.5ml, 17.7mmol) in DCM (20mL) at -78°C. After stirring for 30 min, a solution of compound 1 (1.80 g, 10.5 mmol) in DCM (15 mL) was added dropwise to the above solution, and stirred for 2 min. Stirring was maintained at -78°C for 1 h, then TEA (12 mL, 86.0 mmol) was added dropwise to the above reaction solution. After the addition of TEA is complete, add saturated NH 4 Cl solution (10 mL) quenched the reaction. Then, the temperature of the reaction solution was raised to room temperature, washed with saturated brine (3×20mL), and the organic phase was anhydrous Na 2 SO 4 It was dried, filtered, concentrated, and purified by column chromatography to obtain compound 2 (1.7 g, 95%). 1 H NMR (400MHz, Chloroform-d) δ9.44 (d, J = 6.2Hz, 1H), 4.82 (dt, J = 5.1, 4.2Hz, 1H), 3.94 (qd, J = 5.6, 4.6Hz, 1H) ,3.61(d,J=5.3Hz,1H),...

Embodiment 3

[0147] (1) Synthesis of Compound 2

[0148]

[0149] Dess-Martin oxidant (19 g, 45 mmol) was added portionwise to a solution of compound 1 (5.7 g, 30 mmol) in DCM (200 mL) at 0°C. Then, the reaction was transferred to room temperature, and the reaction was stirred for 2h. After the reaction is complete, place it at 0°C, add saturated sodium thiosulfate solution to quench the reaction, filter with suction, and then add saturated NaHCO to the filtrate 3 solution (50mL) and ethyl acetate (100mL), the layers were separated after standing, the aqueous phase was extracted with ethyl acetate (100mL×2), the organic phases were combined, washed with saturated brine (100mL), and the organic phase was anhydrous Na 2 SO 4 It was dried, filtered, concentrated, and purified by column chromatography to obtain compound 2 (3.8 g, 75%). 1 H NMR (400MHz, Chloroform-d) δ9.44 (d, J = 6.2Hz, 1H), 4.82 (dt, J = 5.1, 4.2Hz, 1H), 3.94 (qd, J = 5.6, 4.6Hz, 1H) ,3.61(d,J=5.3Hz,1H),2.67(q,J=5.9Hz,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com