A preparation method of high-strength aluminum alloy hollow guide rail profile

A hollow guide rail and aluminum alloy technology, applied in the field of aluminum alloy materials, can solve problems such as bending, twisting, difficult shaping and straightening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

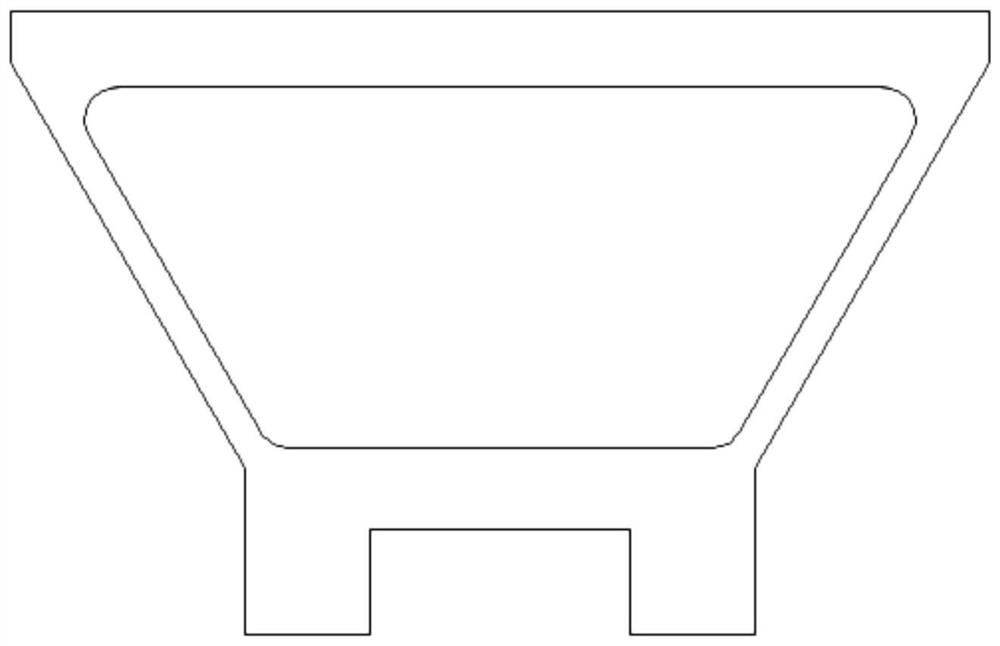

Image

Examples

preparation example Construction

[0023] The invention provides a method for preparing a high-strength aluminum alloy hollow rail profile, comprising:

[0024] Aluminum alloy high-strength hollow rail profiles obtained through ingot heating, extrusion, on-line quenching, stretching, shaping, aging and other processes;

[0025] The temperature of the ingot is 440°C-470°C; the extrusion speed is 2.2-2.9m / min.

[0026] In the present invention, the aluminum alloy is first heated through ingot casting. The ingot casting described in the present invention is an ingot heating process well known to those skilled in the art. Preferably, the ingot casting is carried out in an induction heating furnace. The temperature at the end is high and the temperature at the end is low. The ingot heating temperature is 455°C-470°C at the head end of the ingot, and 440°C-455°C at the tail end of the ingot; °C-450 °C; the most preferred temperature is 462 °C at the head end of the ingot and 448 °C at the tail end of the ingot.

...

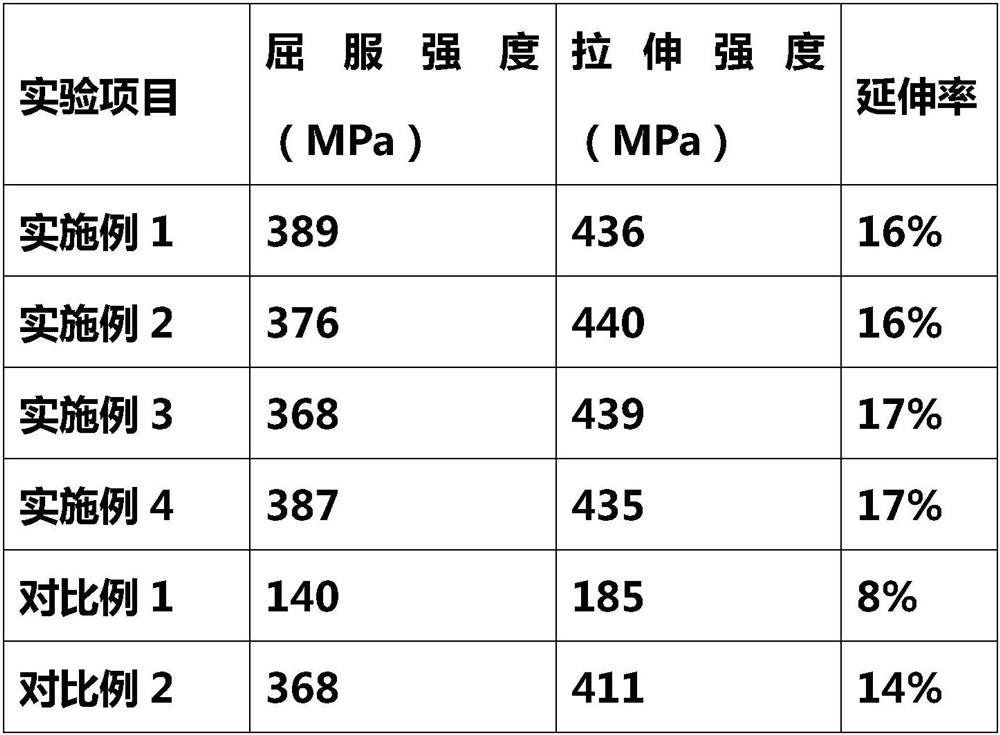

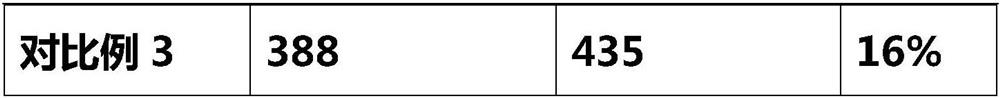

Embodiment 1

[0038] The 7A19 aluminum alloy is heated for ingot casting, adopting the gradient heating method, the ingot heating temperature is 470°C at the head end of the ingot, and the temperature at the tail end of the ingot is 455°C; the mold temperature is 460°C; Extruded on a 366mm cylinder, the temperature of the extrusion cylinder is 450°C, the extrusion speed is 2.5m / min, the outlet temperature of the extruded profile is 500°C; online wind and mist cooling, the cooling rate is 180°C / s, and the on-line process is carried out after quenching. Stretching, using special pads for stretching, controlling the stretching rate to 1.2%, and then aging at 138°C for 16 hours to obtain aluminum alloy guide rail profiles. The bending degree and twisting degree of the high-strength aluminum alloy hollow guide rail profile product prepared in this embodiment are effectively controlled.

Embodiment 2

[0040] The 7A19 aluminum alloy is heated for ingot casting, adopting the gradient heating method, the ingot heating temperature is 470°C at the head end of the ingot, and the temperature at the tail end of the ingot is 455°C; the mold temperature is 460°C; Extruded on a 366mm barrel, the temperature of the extrusion barrel is 450°C, the extrusion speed is 1.0m / min, the outlet temperature of the extruded profile is 465°C; online wind and mist cooling, the cooling rate is 180°C / s, and the on-line process is carried out after quenching Stretching, using special pads for stretching, controlling the stretching rate to 1.2%, and then aging at 138°C for 16 hours to obtain aluminum alloy guide rail profiles. The bending degree and twisting degree of the high-strength aluminum alloy hollow guide rail profile product prepared in this embodiment are effectively controlled.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com