Small-diameter high-strength steel wire for prestressed concrete sleeper and manufacturing method thereof

A technology of high-strength steel wire and manufacturing method, which is applied in the field of prestressed steel wire, can solve the problems of affecting the static load crack resistance and fatigue resistance of concrete sleepers, affecting the stress transfer of the whole model sleeper, and the uneven size of the steel wire to be stretched, so as to reduce the The effect of loss of stress, prolonging service life, and not easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

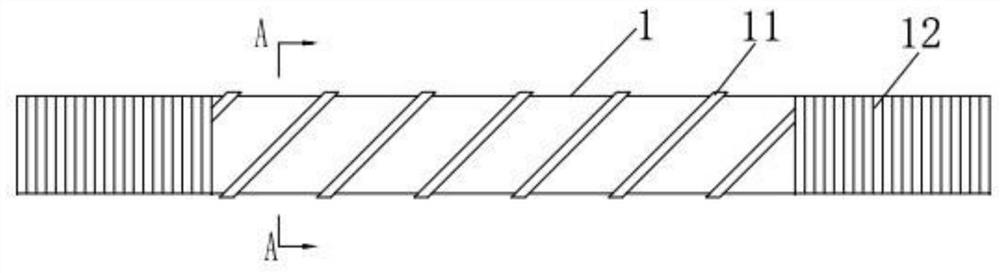

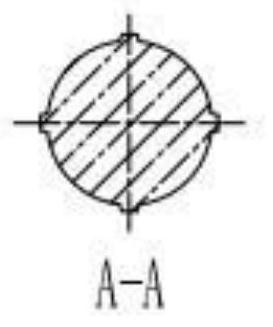

[0041] refer to figure 1 and figure 2 , The present invention provides a small-diameter high-strength steel wire for prestressed concrete sleepers, comprising a steel wire body 1, the length of the steel wire body 1 is 2-6 m, the diameter of the steel wire body 1 is less than 8 mm, and the tensile strength of the steel wire body 1 is not less than 1670MPa; The middle of the steel wire body 1 is provided with a spiral rib 11, the rib height of the spiral rib 11 is 0.275-0.33 mm, and the cross section of the spiral rib 11 is rectangular; ~60mm, the specification of the thread 12 is M4.5~M8, and the pitch range of the thread 12 is 0.5~1.5mm.

[0042] Specifically, in this embodiment, the length of the steel wire body 1 is 2m, the diameter of the steel wire body 1 is 7.5mm, the tensile strength of the steel wire body 1 is 1700MPa, the length of the thread 12 is 20mm, the specification of the thread 12 is M8, and the thread 12 The pitch is 0.75mm.

[0043] The steel wire prepar...

Embodiment 2

[0067] refer to figure 1 and figure 2 , The present invention provides a small-diameter high-strength steel wire for prestressed concrete sleepers, comprising a steel wire body 1, the length of the steel wire body 1 is 3m, the diameter of the steel wire body 1 is 7.0mm, and the tensile strength of the steel wire body 1 is 1800MPa; The middle part of 1 is provided with a spiral rib 11, the rib height of the spiral rib 11 is 0.29-0.34mm, and the cross section of the spiral rib 11 is rectangular; The specification is M7, and the pitch of thread 12 is 0.75mm. All the above specifications and dimensions can achieve the effects mentioned in Embodiment 1.

Embodiment 3

[0069] refer to figure 1 and figure 2 , The present invention provides a small-diameter high-strength steel wire for prestressed concrete sleepers, comprising a steel wire body 1, the length of the steel wire body 1 is 4m, the diameter of the steel wire body 1 is 6.25mm, and the tensile strength of the steel wire body 1 is 1900MPa; The middle part of 1 is provided with a spiral rib 11, the rib height of the spiral rib 11 is 0.30-0.35mm, and the cross section of the spiral rib 11 is rectangular; The specification is M7, and the pitch of thread 12 is 1.0mm. All the above specifications and dimensions can achieve the effects mentioned in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com