Efficient water-washing dechlorinating technology and device for household waste incineration fly ash

A technology of domestic waste incineration and water washing, applied in the field of fly ash treatment, can solve the problems of limiting the harmless disposal and resource utilization of fly ash, increasing energy consumption, increasing the number of washing stages, etc., to ensure the dechlorination effect, The effect of reducing waste water treatment costs and usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

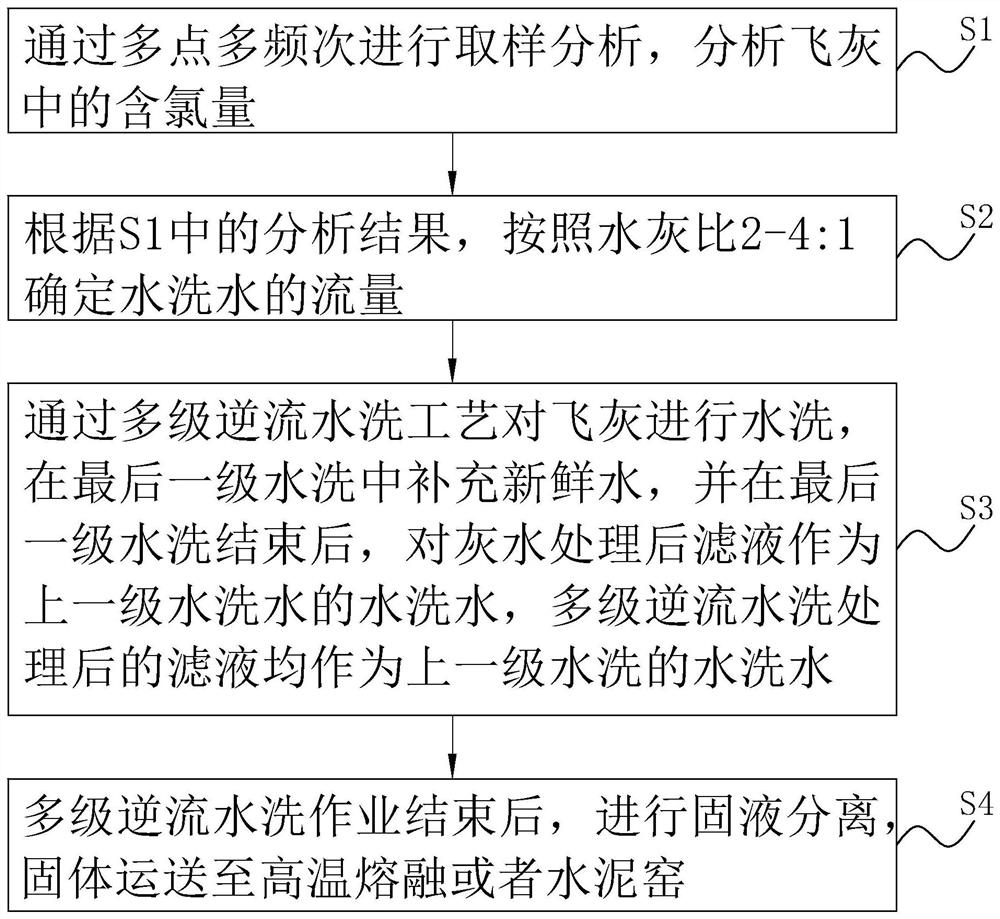

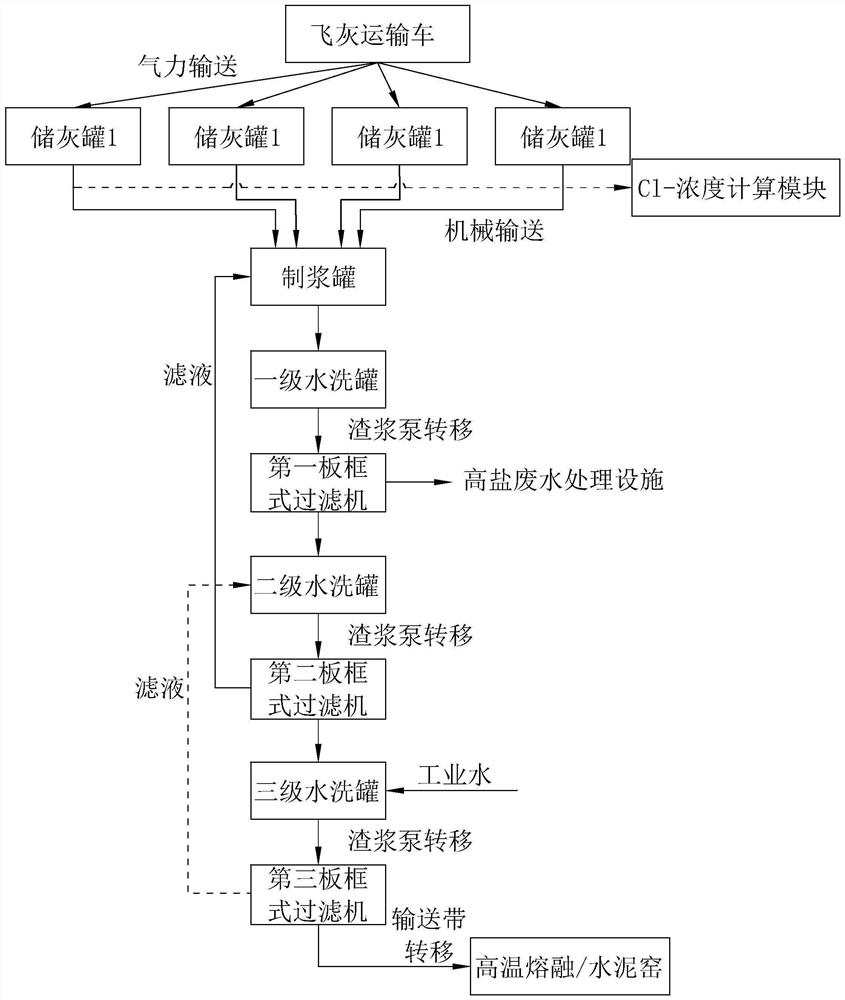

[0035] The following is attached Figure 1-2 The application is described in further detail.

[0036] The embodiment of the present application discloses a high-efficiency water-elution chlorine removal process for domestic waste incineration fly ash. refer to figure 1 , a high-efficiency water-elution chlorine removal process for domestic waste incineration fly ash, the process is as follows:

[0037] S1: Analyze the chlorine content in fly ash through multi-point and multi-frequency sampling analysis;

[0038] S2: According to the analysis results in S1, the flow rate of washing water is determined according to the water-cement ratio of 2-4:1;

[0039] S3: Wash the fly ash through the multi-stage countercurrent washing process, add fresh water in the final stage of washing, and after the final stage of water washing, the filtrate after the gray water treatment is used as the washing water of the previous stage of washing water. The filtrate after the countercurrent washi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com