Ternary metal sulfide nanosheet material and preparation and water electrolysis application thereof

A ternary metal and sulfide technology, applied in the field of materials and energy, can solve problems such as low efficiency, unstable process, complex process, etc., and achieve the reduction of adsorption free energy, fast mass transfer and electron transfer capacity, large specific The effect of surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Ternary metal sulfide nanosheet Fe 0.9 Ni 2.1 S 2 The preparation method of @NF electrocatalyst comprises the following steps:

[0043] 1) Cut blank nickel foam (1cm×2cm) and use acetone, ethanol, and deionized water to sonicate for 15 minutes respectively to remove surface pollutants, and put it in a 60°C oven for 6 hours before using it as a substrate;

[0044] 2) Add 0.81mg of ferric chloride and 1.2mg of sodium sulfide into 50ml of water, fully dissolve to obtain a mixed solution;

[0045] 3) Transfer the above mixed solution to a 100ml reactor;

[0046] 4) Put the cleaned nickel foam into the mixed solution, set the hydrothermal temperature to 150° C. and the hydrothermal time for 6 hours to obtain a ternary metal sulfide nanosheet electrocatalyst;

[0047] 5) The obtained electrocatalyst was washed three times with water and ethanol respectively, and then dried in an oven at 65° C. for 12 hours.

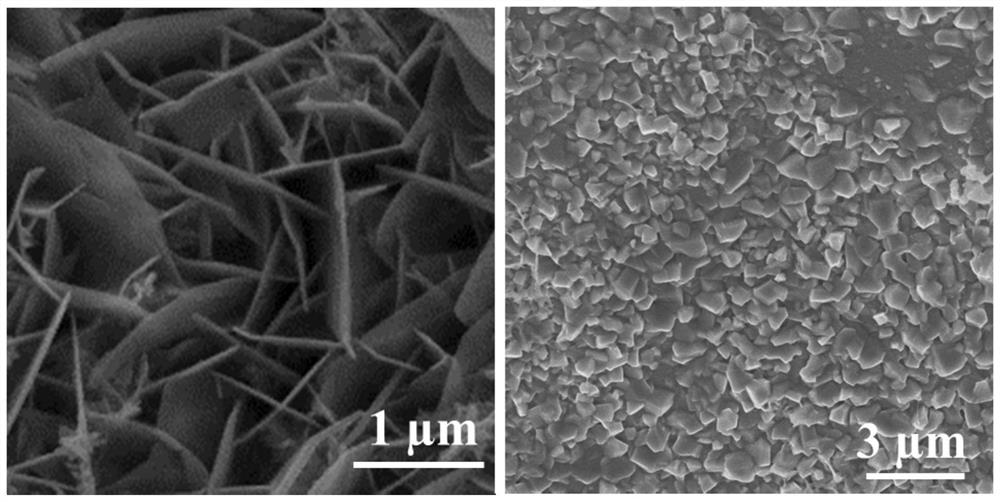

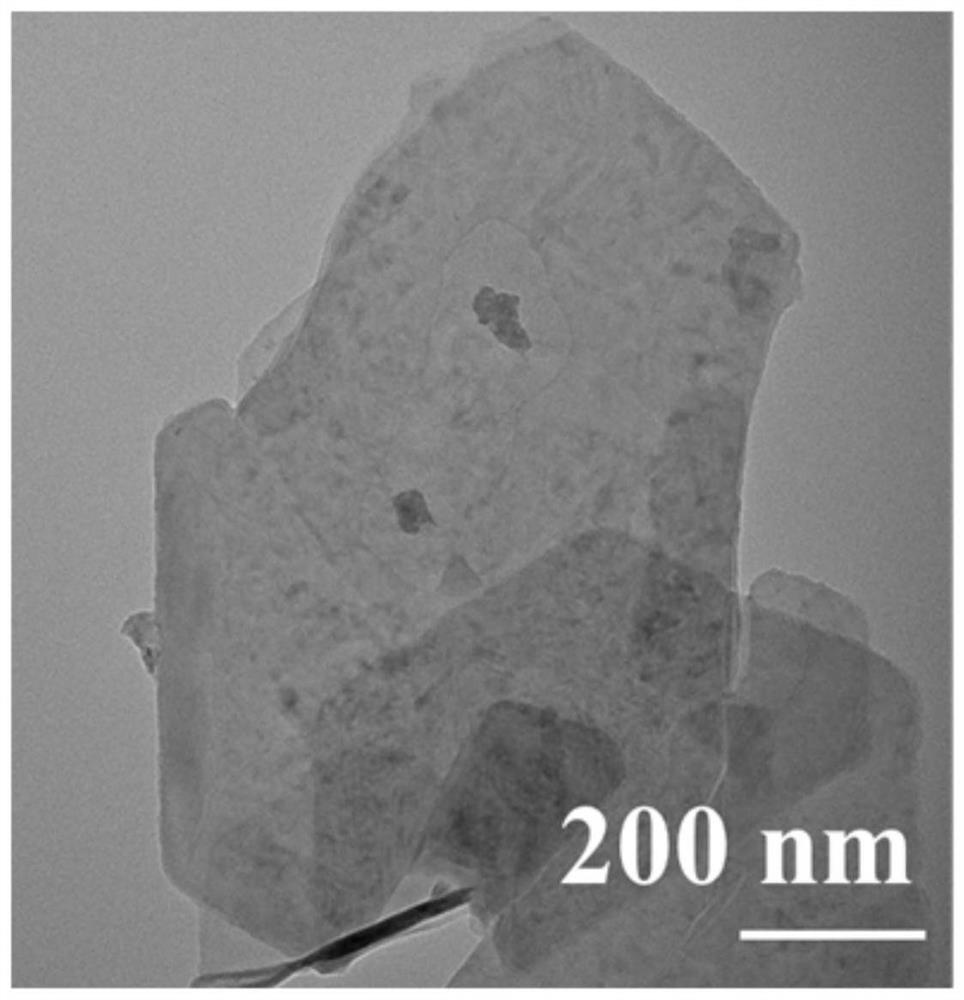

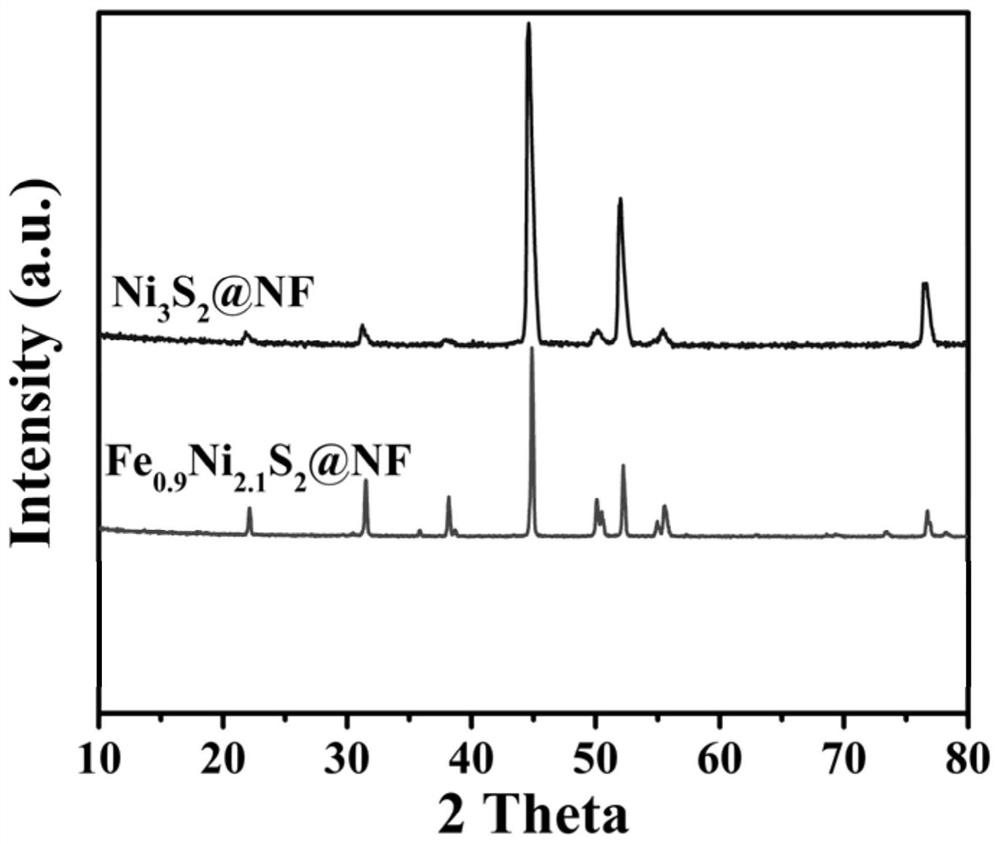

[0048] Fe will be prepared 0.9 Ni 2.1 S 2 @NF electrocataly...

Embodiment 2

[0061] In the present embodiment, nickel foam is changed into copper foam, all the other are the same as embodiment 1, and Fe x Cu 2-x S@CF electrocatalyst.

[0062] Figure 10 for Fe x Cu 2-x S@CF electrocatalyst and Cu prepared without ferric chloride 2 The SEM image of the S@CF electrocatalyst, it can be seen that the Na 2 Particles will be formed during the etching process of S. If Fe doping is introduced simultaneously during the etching process, Cu can be effectively controlled. 2 S forms a hexagonal sheet morphology.

Embodiment 3

[0064] In the present embodiment, foamed nickel is changed to foamed titanium, all the other are the same as embodiment 1, make Fe x Ti y S@TF electrocatalyst.

[0065] Figure 11 for Fe x Ti y SEM images of S@TF electrocatalyst and TiS@TF electrocatalyst prepared without ferric chloride, it can be seen that the amorphous TiS changes from a three-dimensional network structure to a nanosheet structure after Fe doping.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com