A self-supporting bimetallic nickel-tungsten carbide total water-splitting material and its preparation method

A bimetallic and carbide technology, which is applied in the field of self-supporting bimetallic nickel-tungsten carbide full hydrolysis materials and its preparation, can solve the problems of poor stability, poor conductivity and low catalytic activity, achieve good stability and improve catalytic performance. Active, diffusion-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

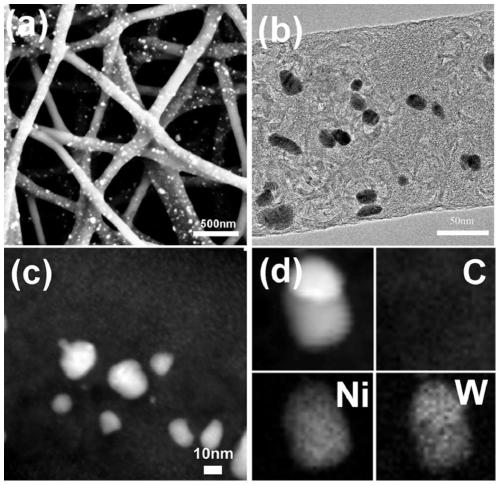

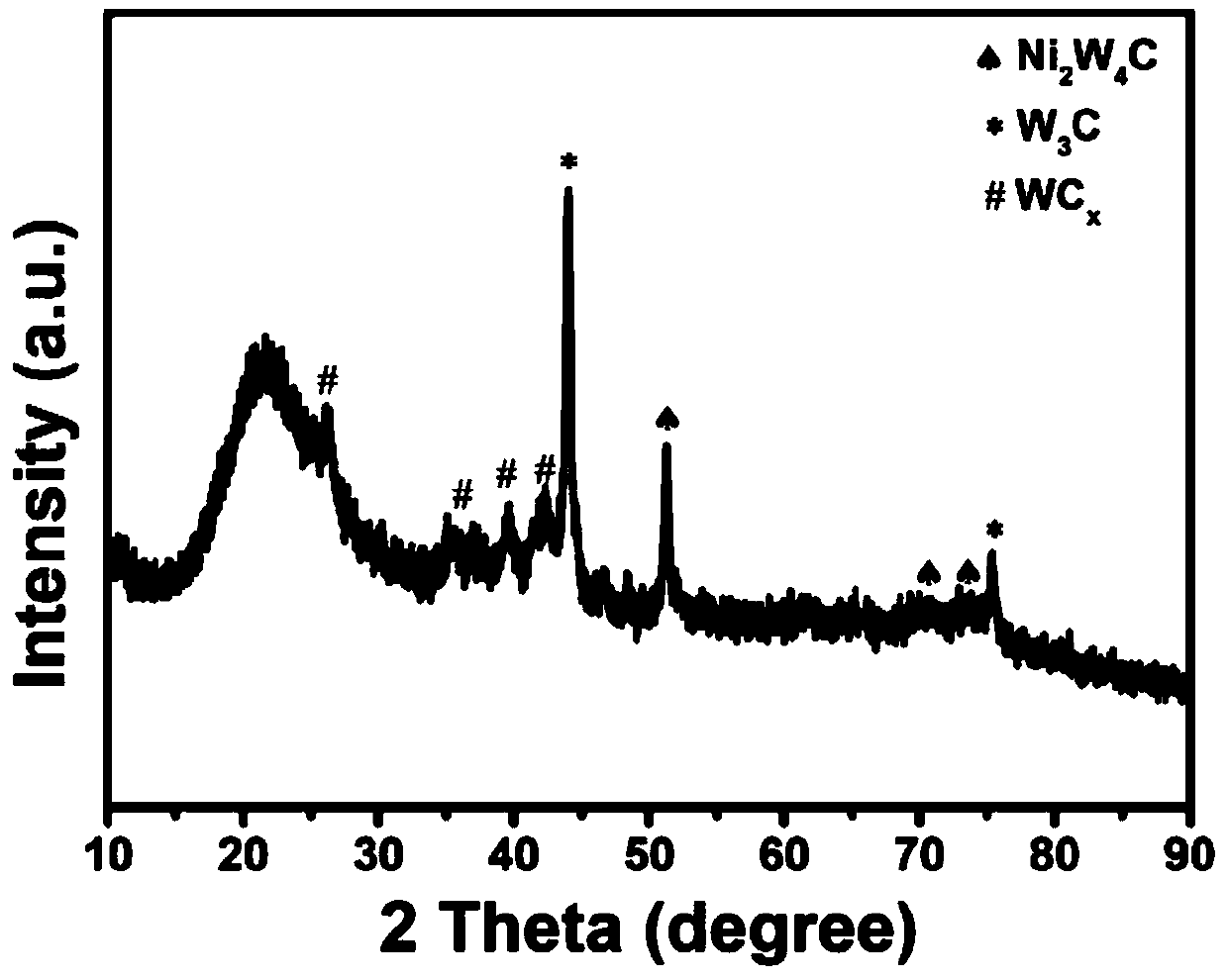

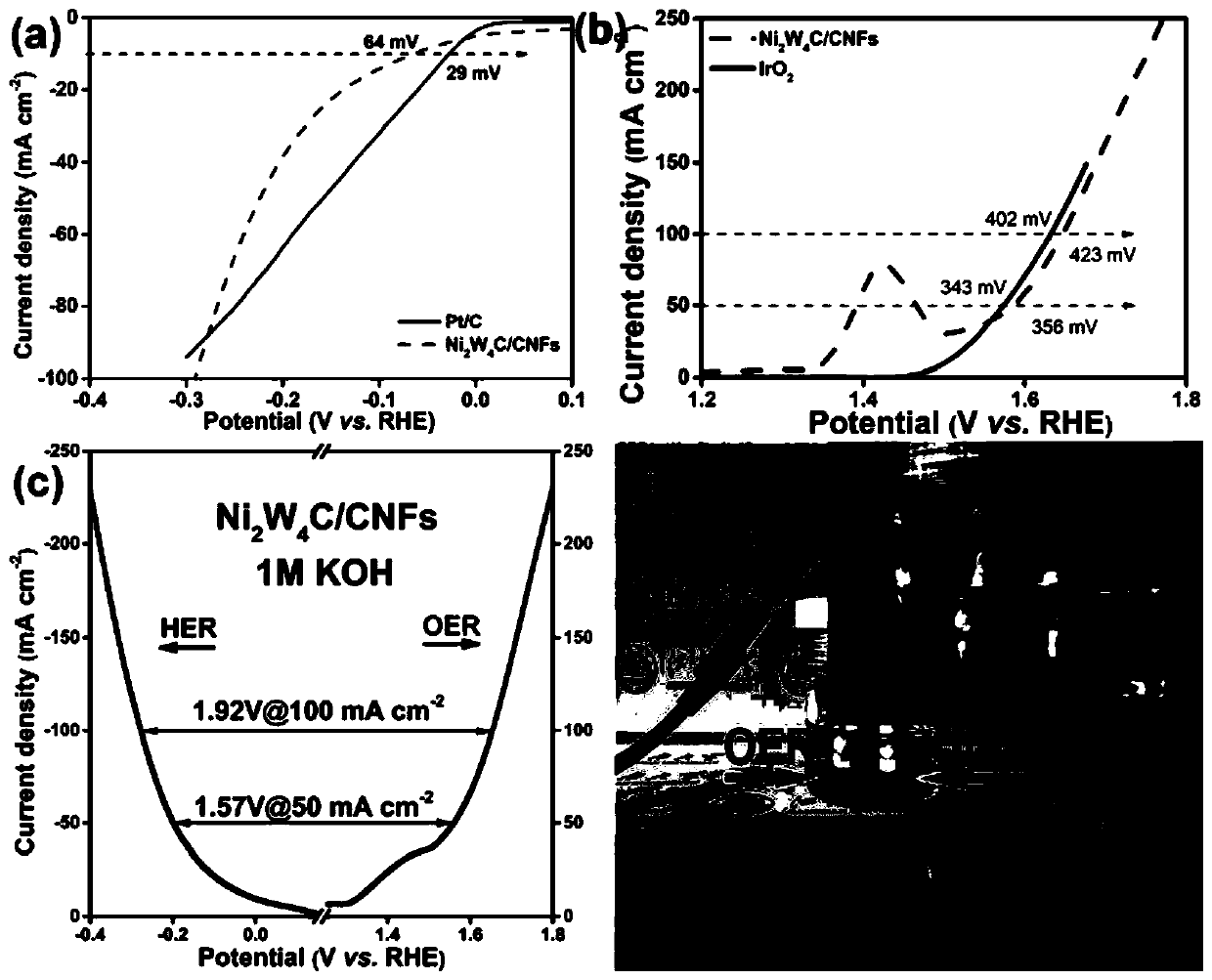

[0037] A method for preparing a nickel-tungsten double metal carbide high-efficiency electrolyzed water material of the present invention comprises the following steps:

[0038] (1) The organic polymer polyacrylonitrile powder is joined in N, N-dimethylformamide solvent, is configured into the spinning solution of mass concentration 12%, gets 0.5g nickel nitrate and 0.5g ammonium metatungstate and joins in In 29 g of polyacrylonitrile / N,N-dimethylformamide solution with a mass fraction of 12 wt%, a uniformly mixed solution was obtained after magnetic stirring for 6 hours, and then the solution was spun by electrospinning, and the spinning was controlled. The wire voltage range is 15kV, the distance from the spinning needle to the receiving device is 10cm, the solution flow rate is 0.05mL / min, and the precursor mixed nanofiber membrane is obtained after continuous spinning for 12 hours;

[0039] (2) Put 0.4g of the mixed nanofiber membrane prepared in step (1) into a corundum b...

Embodiment 2

[0045] A method for preparing a nickel-tungsten double metal carbide high-efficiency electrolyzed water material of the present invention comprises the following steps:

[0046] (1) The organic polymer polyacrylonitrile powder is joined in N, N-dimethylformamide solvent, is configured into the spinning solution of mass concentration 15%, gets 0.3g nickel nitrate and 0.7g ammonium metatungstate and joins in In 15g of polyacrylonitrile / N,N-dimethylformamide solution with a mass fraction of 15wt%, a uniformly mixed solution was obtained after magnetic stirring for 6 hours, and then the solution was spun by electrospinning, and the spinning method was controlled. The wire voltage range is 22kV, the distance from the spinning needle to the receiving device is 18cm, the solution flow rate is 0.1mL / min, and the precursor mixed nanofiber membrane is obtained after continuous spinning for 12 hours;

[0047] (2) Put 0.4g of the mixed nanofiber membrane prepared in step (1) into a corund...

Embodiment 3

[0050] A method for preparing a nickel-tungsten double metal carbide high-efficiency electrolyzed water material of the present invention comprises the following steps:

[0051] (1) The organic polymer polyacrylonitrile powder is joined in N, N-dimethylformamide solvent, is configured into the spinning solution of mass concentration 10%, gets 0.6g nickel nitrate and 0.4g ammonium metatungstate and joins in In 20 g of polyacrylonitrile / N,N-dimethylformamide solution with a mass fraction of 14 wt%, a uniformly mixed solution was obtained after magnetic stirring for 6 hours, and then the solution was spun by electrospinning, and the spinning was controlled. The wire voltage range is 13kV, the distance from the spinning needle to the receiving device is 12cm, the solution flow rate is 0.15mL / min, and the precursor mixed nanofiber membrane is obtained after continuous spinning for 12 hours;

[0052] (2) Put 0.4g of the mixed nanofiber membrane prepared in step (1) into a corundum b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com