Traditional Chinese medicine composition for diminishing inflammation and relieving pain and preparation method thereof

An anti-inflammatory and analgesic composition technology, which is applied in the anti-inflammatory and analgesic traditional Chinese medicine composition and its preparation field, can solve the problems of drug resistance, even shock, and drug-resistant bacteria in microorganisms that treat diseases, achieve good therapeutic effects, and improve human health. The ability of phagocytic cells and the effect of eliminating inflammation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

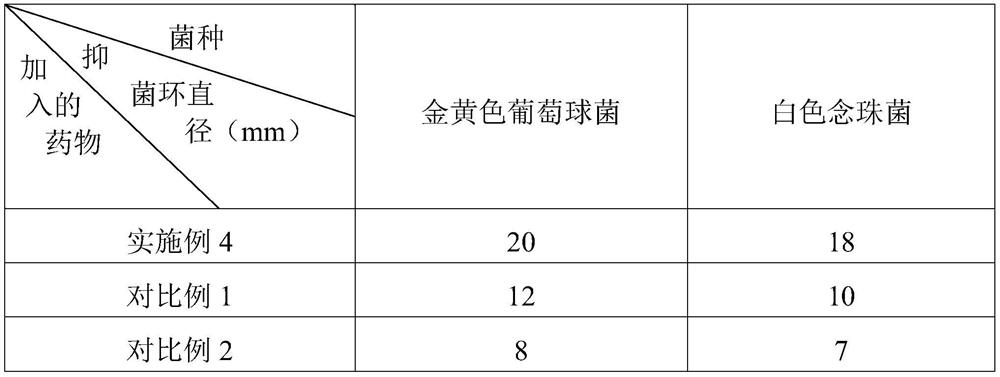

Examples

Embodiment 1

[0047] A traditional Chinese medicine composition for anti-inflammatory and pain-relieving, comprising the following raw materials:

[0048] ice flakes 8g,

[0049] Borax 12g,

[0050] Glauber's salt 8g,

[0051] Camphor 8g,

[0052] Peppermint cream 12g;

[0053] The preparation method of the mint cream is as follows: take dried mint leaves, pulverize, sieve, add to 7 times the weight of water, and distill to obtain mint crude oil, add the mint crude oil to the extraction kettle, and extract with supercritical carbon dioxide. The temperature of critical carbon dioxide extraction is 37° C., the pressure is 8.5 MPa, and the flow rate of carbon dioxide is 2 L / min to obtain peppermint oil. The peppermint oil is cooled and crystallized at -20° C. to obtain the peppermint cream.

[0054] The preparation method of the above-mentioned anti-inflammatory and analgesic Chinese medicine composition comprises the following steps:

[0055] (1) Weigh borneol, borax, thenardite, camphor...

Embodiment 2

[0058] A traditional Chinese medicine composition for anti-inflammatory and pain-relieving, comprising the following raw materials:

[0059] ice flakes 12g,

[0060] Borax 20g,

[0061] Glauber's salt 12g,

[0062] Camphor 12g,

[0063] 20g mint cream;

[0064] The preparation method of the mint cream is as follows: take dried mint leaves, pulverize, sieve, add to 10 times the weight of water, distill to obtain mint crude oil, add mint crude oil to an extraction kettle, and extract with supercritical carbon dioxide. The temperature of critical carbon dioxide extraction is 45° C., the pressure is 9.5 MPa, and the flow rate of carbon dioxide is 4 L / min to obtain peppermint oil. The peppermint oil is cooled and crystallized at 0° C. to obtain the peppermint cream.

[0065] The preparation method of the above-mentioned anti-inflammatory and analgesic Chinese medicine composition comprises the following steps:

[0066] (1) Weigh borneol, borax, thenardite, camphor and mint cre...

Embodiment 3

[0069] A traditional Chinese medicine composition for anti-inflammatory and pain-relieving, comprising the following raw materials:

[0070] ice flakes 10g,

[0071] Borax 15g,

[0072] Glauber's salt 9g,

[0073] Camphor 11g,

[0074] Peppermint cream 18g;

[0075] The preparation method of the mint cream is as follows: take dried mint leaves, pulverize, sieve, add to 8 times the weight of water, and distill to obtain mint crude oil, add the mint crude oil to the extraction kettle, and extract with supercritical carbon dioxide. The temperature of the critical carbon dioxide extraction is 40° C., the pressure is 9 MPa, and the flow rate of carbon dioxide is 2 L / min to obtain peppermint oil. The peppermint oil is cooled and crystallized at -20° C. to obtain the peppermint cream.

[0076] The preparation method of the above-mentioned anti-inflammatory and analgesic Chinese medicine composition comprises the following steps:

[0077] (1) Weigh borneol, borax, thenardite, cam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com