Improved modular photovoltaic module bypass element and module junction box

A photovoltaic module and bypass element technology, applied in the field of solar photovoltaic power generation, can solve the problems of reduced production efficiency, disadvantageous cost reduction and efficiency increase, and increased production cost of junction boxes, so as to improve efficiency, save investment, and avoid secondary switching. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are provided in conjunction with the embodiments.

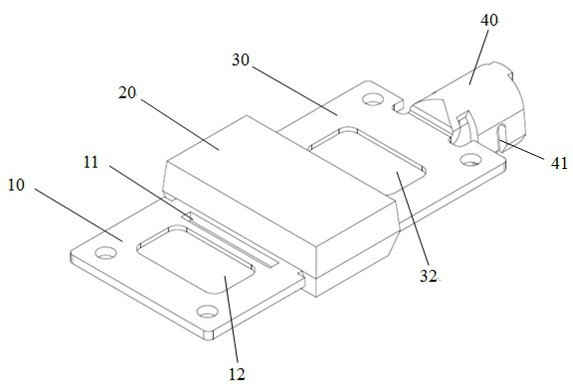

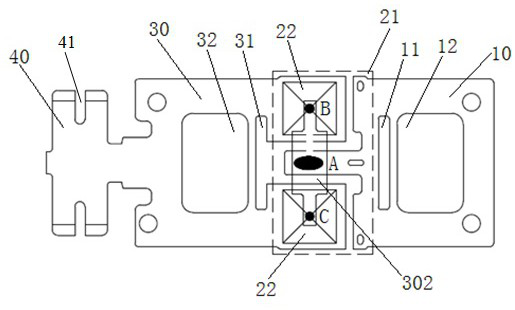

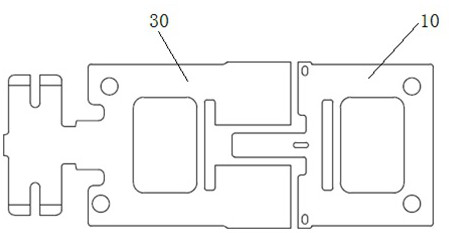

[0025] See figure 1 Shown is a three-dimensional structural schematic diagram of an improved modular photovoltaic module bypass element of the present invention, the modular photovoltaic module bypass element includes a first conductive terminal 10, a diode packaging module 20 and a second conductive terminal 30, see figure 2 The diode packaging module 20 is arranged between the first conductive terminal 10 and the second conductive terminal 30, the diode packaging module 20 includes an insulating plastic package 21, a diode chip 22 placed inside the insulating plastic package 21, and a connection between the diode chip and the The electrical connecting piece 302 of the conductive terminal, the inner end of the first conductive terminal 10 and the inner end of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com