A kind of ferroferric oxide/silicon oxide/multilayer graphene composite material and preparation method thereof

A multi-layer graphene, ferric oxide technology, applied in the field of materials, can solve the problems of unsuitability for industrial production, easy pulverization of active materials, reduced cycle performance, etc., and achieves low cost, short reaction time, and small particle diameter. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to better illustrate the process and solutions of the present invention, the following inventions will be further described in conjunction with the accompanying drawings and embodiments. The specific embodiments described here are only used to explain the present invention, not to limit the present invention.

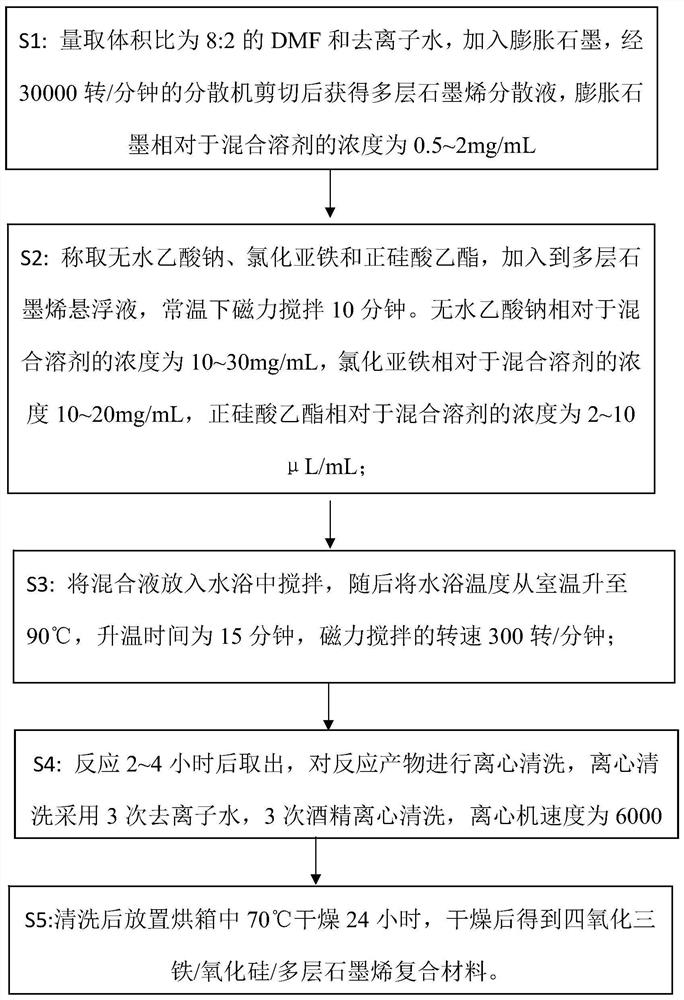

[0031] In order to solve the technical problems existing in the prior art, see figure 1 , which is a flow chart of the preparation method of a method for uniformly distributing nanometer ferric oxide and silicon dioxide particles on multi-layer graphene proposed by the present invention. And in conjunction with the following 3 examples, the preparation process is described in detail.

[0032] instantiate 1

[0033] Step S1, measure DMF and deionized water with a volume ratio of 8:2, add expanded graphite, and obtain a multilayer graphene dispersion after being sheared by a disperser at 30,000 rpm for 30 minutes. The ratio of expanded graphite to the mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com