Method for evaluating quality of coke for lithium battery negative electrode material

A negative electrode material, lithium battery technology, applied in the preparation of analytical materials, test samples, and weighing by removing certain components, can solve the problems of cumbersome sample preparation, shortening detection time, waste, etc., and achieve fast and sensitive analysis. , The effect of strong operability and less sample volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Sampling 50-100g of needle coke raw coke, spreading it in a thin layer on an iron pan, drying it naturally, coarsely crushing it with a jaw crusher, and sieving it through a 4mm sieve to obtain primary coke powder;

[0024] Put the primary coke powder sample into an alumina crucible, heat-treat it for 20-60 minutes at 700-800°C in a nitrogen atmosphere, and pulverize it with a shearing mill until it passes through a sieve of 0.071 mm to obtain a secondary coke powder;

[0025] The secondary coke powder is divided into two batches, one batch is tested by itself for thermogravimetry; the other batch is sent to the battery manufacturer for charge and discharge detection and graphitization degree test according to the traditional method:

[0026] Among them, the specific method of self-test thermogravimetry is:

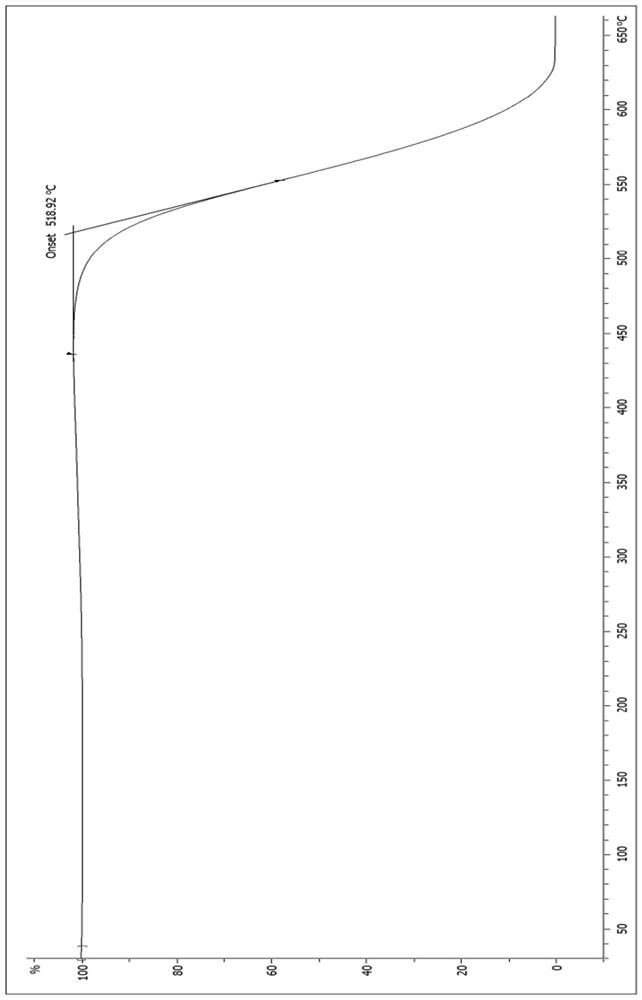

[0027] Evenly weigh ≮5mg of the secondary coke powder, place it in a 70ml alumina crucible, and heat it at a rate of 2-5°C / min from 50°C to 900°C in an air atmosph...

Embodiment 2

[0032] Sampling 50-100g of pitch coke raw coke, spreading it in a thin layer on an iron pan, drying it naturally, coarsely crushing it with a jaw crusher, and sieving it through a 4mm sieve to obtain primary coke powder;

[0033] Put the primary coke powder sample into an alumina crucible, heat-treat it for 20-60 minutes at 700-800°C in a nitrogen atmosphere, and pulverize it with a shearing mill until it passes through a sieve of 0.071 mm to obtain a secondary coke powder;

[0034] The secondary coke powder is divided into two batches, one batch is tested by itself for thermogravimetry; the other batch is sent to the battery manufacturer for charge and discharge detection and graphitization degree test according to the traditional method:

[0035] Among them, the specific method of self-test thermogravimetry is:

[0036] Evenly weigh ≮5mg of the secondary coke powder, place it in a 70ml alumina crucible, and heat it at a rate of 2-5°C / min from 50°C to 900°C in an air atmosphe...

Embodiment 3

[0041] Sampling 50-100g of homogeneous coke raw coke, laying a thin layer on an iron plate, after natural drying, coarsely crushing with a jaw crusher, and sieving through 4mm to obtain primary coke powder;

[0042] Put the primary coke powder sample into an alumina crucible, heat-treat it for 20-60 minutes at 700-800°C in a nitrogen atmosphere, and pulverize it with a shearing mill until it passes through a sieve of 0.071 mm to obtain a secondary coke powder;

[0043] The secondary coke powder is divided into two batches, one batch is tested by itself for thermogravimetry; the other batch is sent to the battery manufacturer for charge and discharge detection and graphitization degree test according to the traditional method:

[0044] Among them, the specific method of self-test thermogravimetry is:

[0045] Evenly weigh ≮5mg of the secondary coke powder, place it in a 70ml alumina crucible, and heat it at a rate of 2-5°C / min from 50°C to 900°C in an air atmosphere with a flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com