Preparation method of textile fragrance treatment microcapsule

A technology for microcapsules and textiles, which is applied to the preparation of textile fragrance treatment microcapsules and the field of microcapsule preparation, can solve the problems of high permeability and high volatility of fragrance essential oils, instability of fragrance oils, insufficient consideration of fragrance oils, and impact on product quality. and other problems, to achieve the effect of changing the characteristics of high permeability and high volatility, long fragrance retention time, and convenient coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

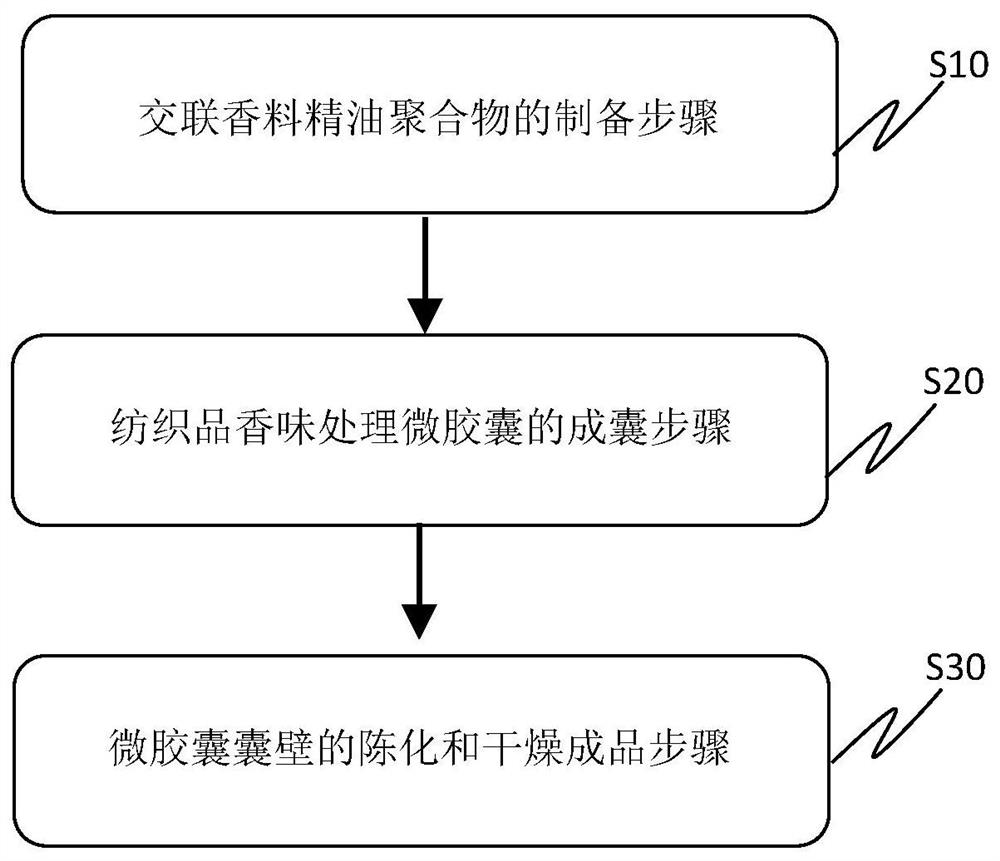

[0055] like figure 1 As shown in the flowchart of a preparation method of a textile fragrance treatment microcapsule provided by the embodiment of the present invention:

[0056] A method for preparing textile fragrance treatment microcapsules, comprising:

[0057] S10) the preparation step of cross-linked fragrance essential oil polymer, including:

[0058] S11) dissolving xylylene diisocyanate in ethyl acetate to obtain an aliphatic isocyanate polymer;

[0059] S12) mixing and stirring the fragrance essential oil and the aliphatic isocyanate polymer to generate a crosslinked fragrance essential oil polymer;

[0060] S20) The encapsulation step of textile fragrance treatment microcapsules, including:

[0061] S21) adding a cross-linked perfume essential oil polymer to the acrylamide solution to form a mixed solution, adjusting the mixed solution to acidity with acetic acid, heating and stirring the mixed solution to obtain a cross-linked perfume essential oil polymer-acryl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| encapsulation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com