Anode effect detecting method based on anode guide rod vibration

An anode guide rod and anode effect technology, which is applied in the field of anode effect detection based on the vibration of the anode guide rod, can solve the problems of vibration of the anode guide rod, reducing the number of occurrences of the anode effect or extinguishing it in time, and being unable to predict the occurrence or location of the anode effect. Achieve the effect of low input cost and reduce data labeling resource input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

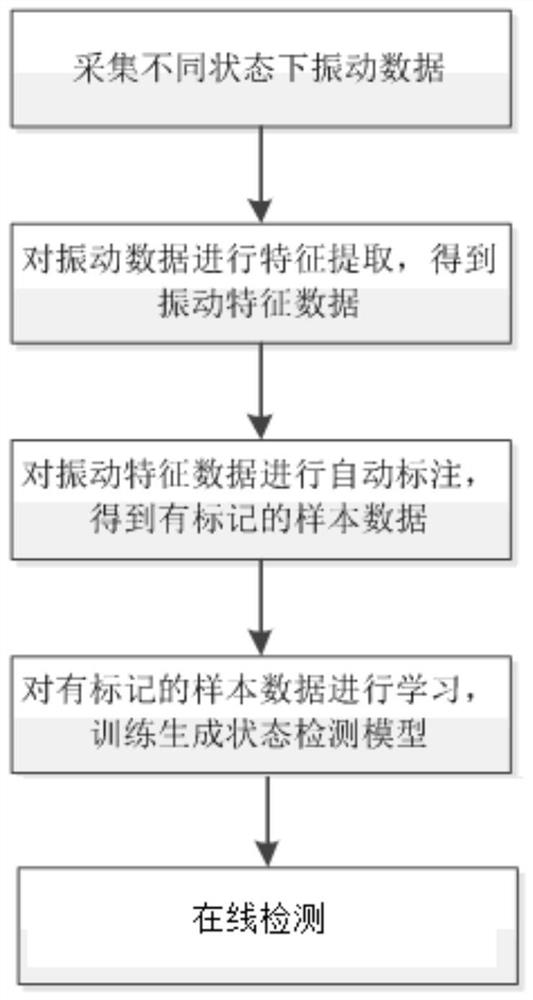

[0033] Such as figure 1 As shown, a kind of anode effect detection method based on the vibration of the anode guide rod of the present invention comprises:

[0034] Step 1: Collect the vibration data of the anode guide rod in different states;

[0035] Step 2: Perform feature extraction on the vibration data to obtain vibration feature data;

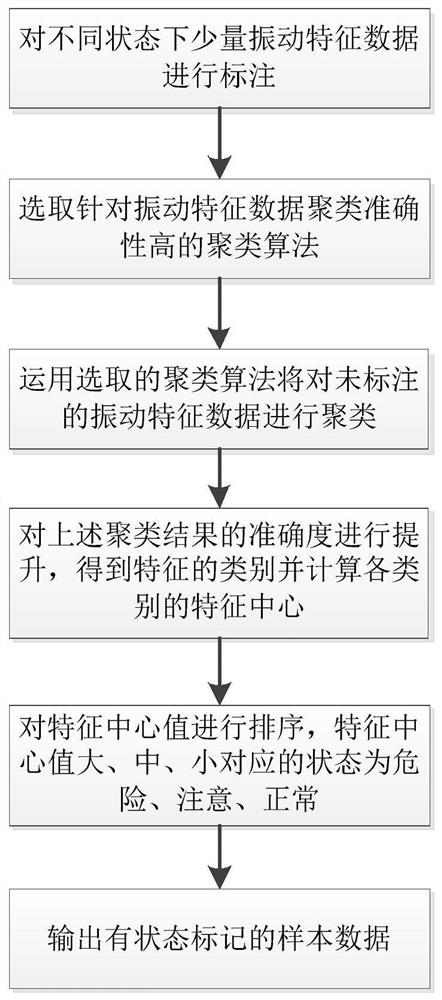

[0036] Step 3: Automatically mark the vibration characteristic data to obtain marked sample data;

[0037] Step 4: Learn the labeled sample data, train and generate a state detection model;

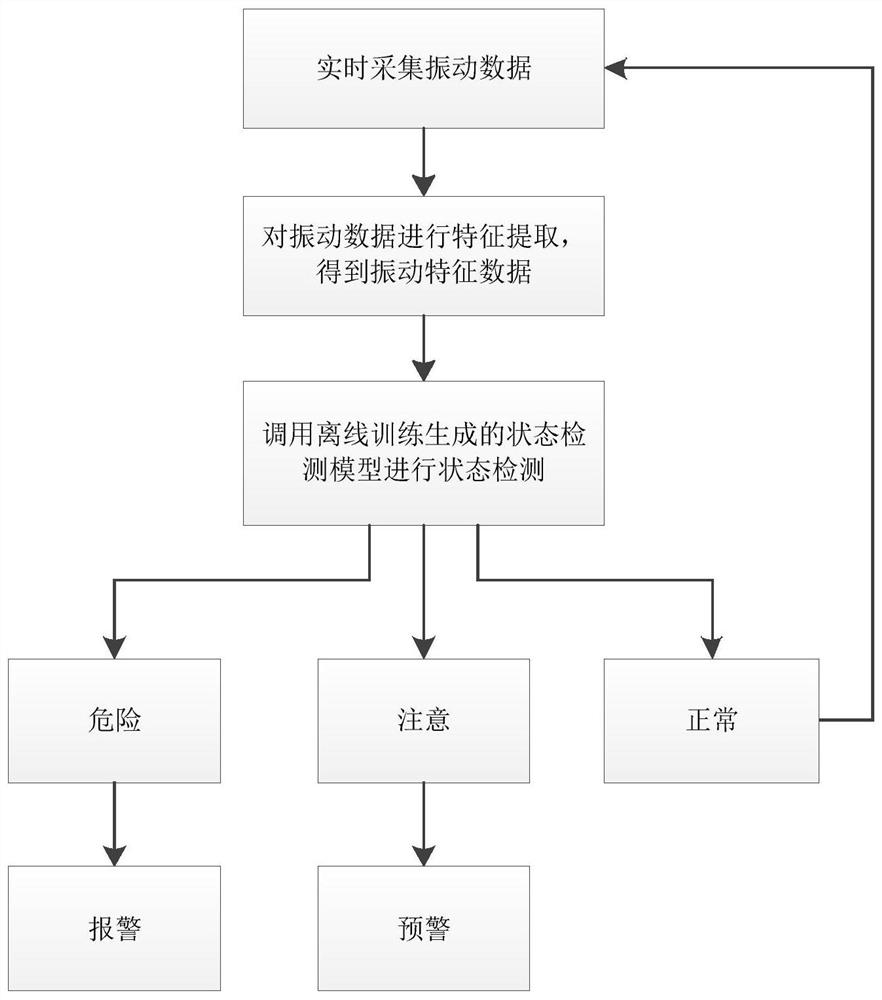

[0038] Step 5: During online detection, collect real-time vibration data, perform feature extraction on the real-time vibration data, input the obtained real-time vibration feature data into the trained state detection model for state detection, and send corresponding signals according to the detection results.

[0039] This method detects the anode effect based on the vibration of the anode guide rod caused by the bubble generation process. By ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com