Low-concentration refractory chemical wastewater treatment method and system

A technology for chemical wastewater and treatment methods, which is applied in the fields of special compound water treatment, oxidized water/sewage treatment, water/sewage treatment, etc. It can improve the effect of catalytic oxidation, ensure the effect of biochemical treatment, reduce sludge loss and process area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

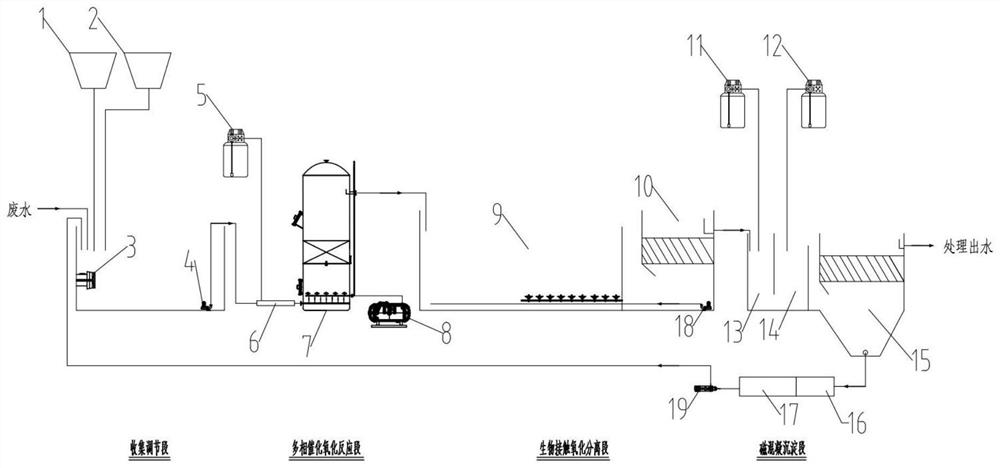

[0048] Production wastewater of a chemical company in Hebei, water volume 60m 3 / h, the main pollutants are production raw materials and reaction intermediates, specifically benzene ring substances, which are treated by the following process:

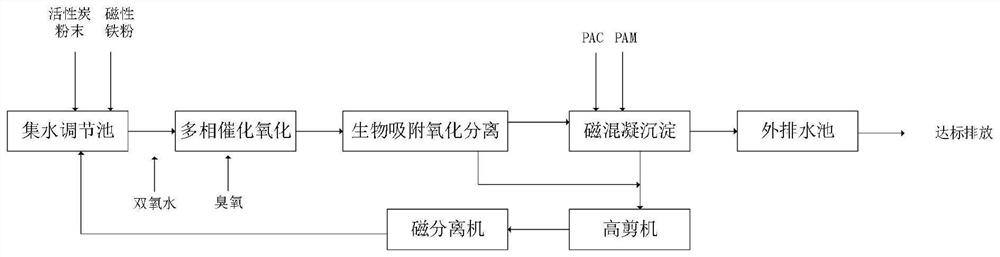

[0049] Process 1: The method of the present invention ("Water collection adjustment + heterogeneous catalytic oxidation + biosorption oxidation separation + magnetic coagulation precipitation")

[0050] Process 2: Water collection adjustment + ozone catalytic oxidation + SBR + coagulation sedimentation

[0051] Process 3: Water collection regulation + Fenton + AAO + coagulation and sedimentation

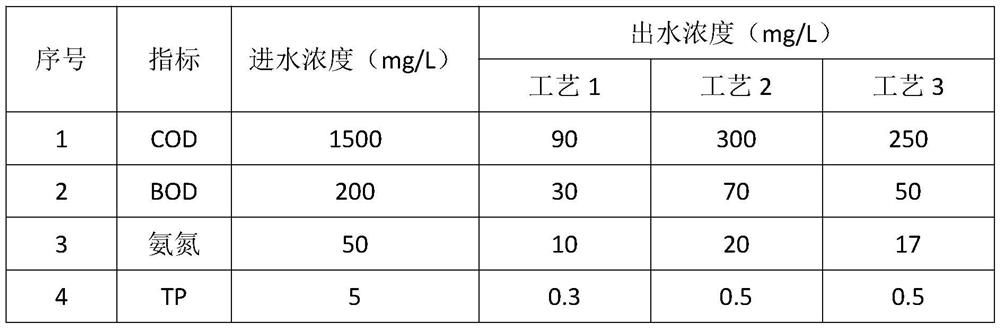

[0052] The effect of the treatment process is as follows in Table 1

[0053]

[0054] According to the above experimental results, when the influent COD is 1500mg / L, BOD is 200mg / L, ammonia nitrogen is 50mg / L, and TP is 5mg / L, the effluent can reach COD≤300mg / L and BOD≤ 70mg / L, ammonia nitrogen≤20mg / L, TP≤0.5mg / L, the removal rates reach...

Embodiment 2

[0056] Production wastewater of a chemical company in Gansu, water volume 150m 3 / h, the main pollutants are production raw materials and reaction intermediates, specifically organic synthetic polymer compounds, which are carried out by the process of the present invention ("water collection adjustment + heterogeneous catalytic oxidation + biological adsorption oxidation separation + magnetic coagulation precipitation") Treatment, influent COD 800mg / L, BOD 100mg / L, ammonia nitrogen 20mg / L, TP3mg / L, activated carbon powder dosage 15mg / L, magnetic iron powder dosage 3mg / L, ozone dosage 1mg / mg COD , the dosage of 30% concentration of hydrogen peroxide is 20mg / mg COD, the residence time of regulating tank is 12 hours, the residence time of heterogeneous catalytic oxidation is 2 hours, the residence time of biosorption oxidation separation tank is 24 hours, the residence time of magnetic coagulation sedimentation tank is 30min, and the final effluent COD Less than 40mg / L, BOD less ...

Embodiment 3

[0058] Production wastewater of a chemical company in Shandong, water volume 100m 3 / h, the main pollutants are production raw materials and reaction intermediates, specifically polycyclic aromatic hydrocarbons. Take some water samples and use the process of the present invention ("water collection adjustment + multi-phase catalytic oxidation + biological adsorption oxidation separation + magnetic coagulation precipitation") process to explore the dosage of different activated carbon powder, magnetic iron powder, ozone and hydrogen peroxide Influence on its processing effect:

[0059] Condition 1: dosage of activated carbon powder: 20mg / L, dosage of magnetic iron powder: 5mg / L, dosage of ozone 2mg / mgCOD, dosage of 30% hydrogen peroxide 5mg / mgCOD.

[0060] Condition 2: dosage of activated carbon powder: 5mg / L, dosage of magnetic iron powder: 5mg / L, dosage of ozone 2mg / mgCOD, dosage of 30% hydrogen peroxide 5mg / mg COD.

[0061] Condition 3: dosage of activated carbon powder: 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com