Method for preparing nano TiO2 by adding template agent through dynamic microwave method

A template agent, microwave method technology, applied in the field of preparing photocatalyst materials, can solve problems such as increased input cost, and achieve the effects of short reaction time, simple process and less impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

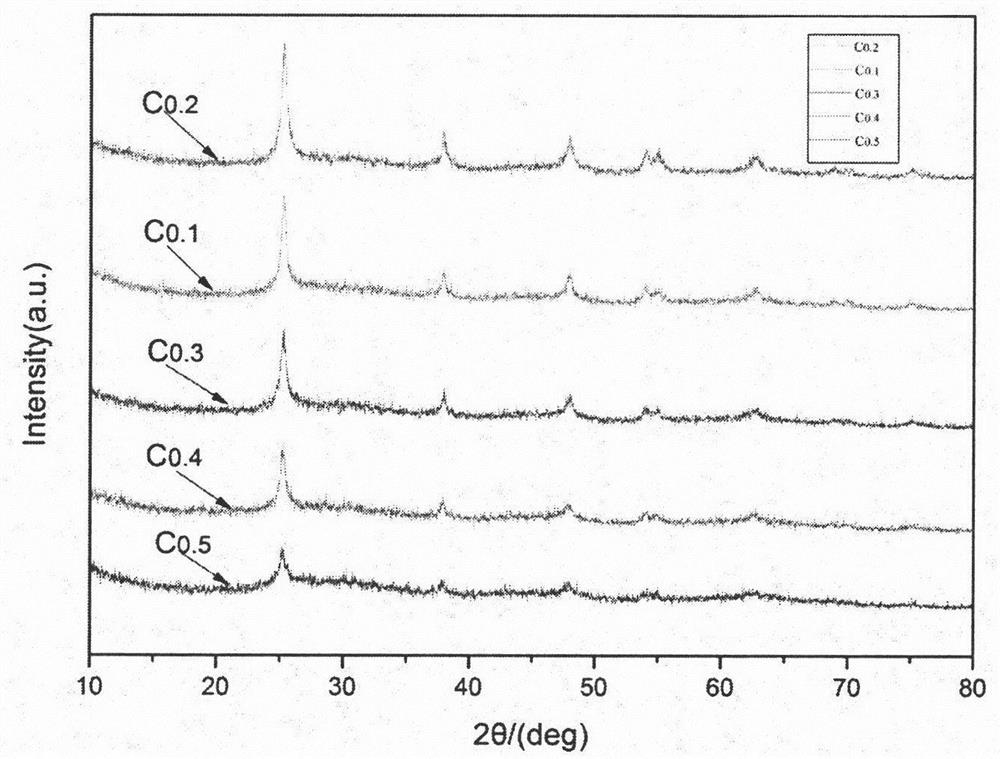

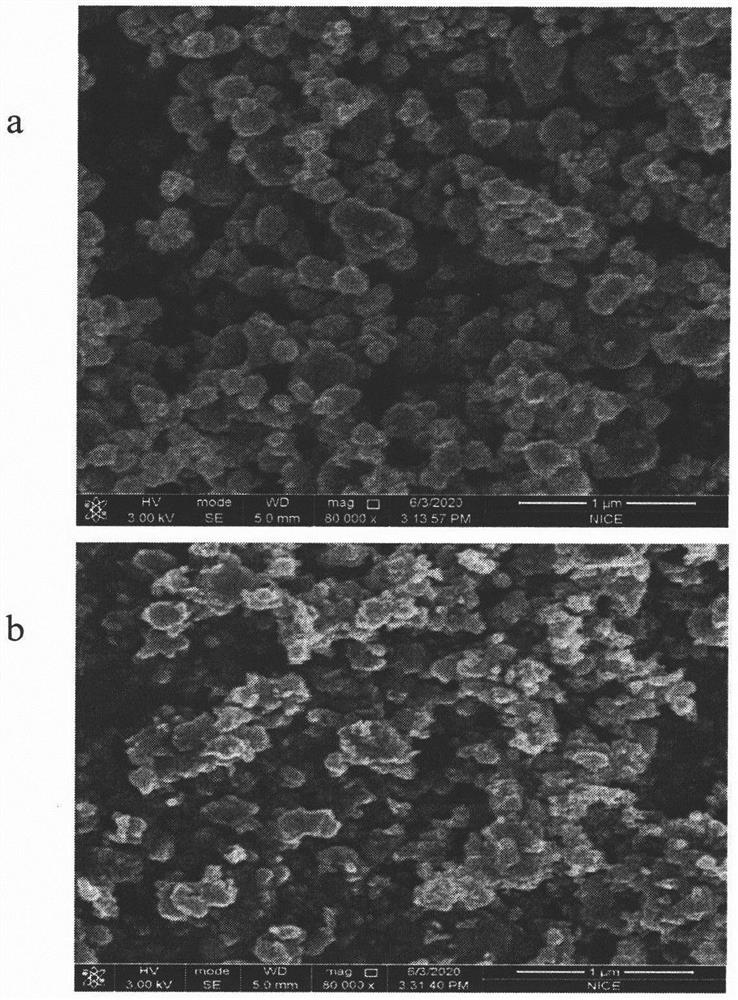

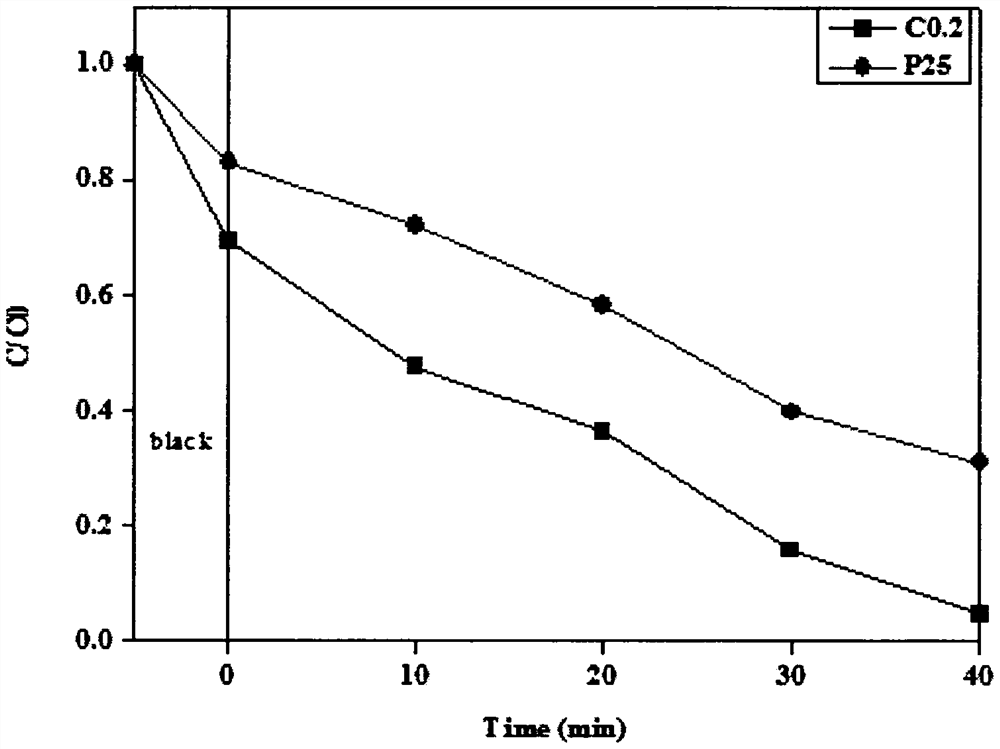

Embodiment 1

[0016] Take 7.7mL of tetrabutyl titanate and slowly add it into 30mL of absolute ethanol while stirring under ultrasonic conditions, and drop the above mixed solution into 50mL of deionized water with a peristaltic pump with a rotation speed of 25rpm. Stir under ultrasonic conditions, and ensure that the temperature of the ultrasonic water bath is 10 ° C, measure 4 mL of CTAB with a concentration of 4 g / L and slowly add it dropwise into the prepared tetrabutyl titanate solution, and finally mix the above mixed solution with deionized water Dilute to 100mL and continue to sonicate for 10min. Take 25mL of the prepared precursor mixture and put it into the reactor. Under the condition of energy input of 50W in the ring microwave field, keep the temperature at 140°C, and continue to react for 3 hours, and keep stirring during the reaction. After the reaction, wait for the reaction The kettle was naturally cooled to room temperature, and the reaction suspension was centrifuged to o...

Embodiment 2

[0019] Take 7.7mL of tetrabutyl titanate and slowly add it into 30mL of absolute ethanol while stirring under ultrasonic conditions, and drop the above mixed solution into 50mL of deionized water with a peristaltic pump with a rotation speed of 25rpm. Stir under ultrasonic conditions, and ensure that the temperature of the ultrasonic water bath is 10 ° C, measure 4 mL of CTAB with a concentration of 8 g / L and slowly add it dropwise into the prepared tetrabutyl titanate solution, and finally mix the above mixed solution with deionized water Dilute to 100mL and continue to sonicate for 10min. Take 25mL of the prepared precursor mixture and put it into the reactor. Under the condition of energy input of 50W in the ring microwave field, keep the temperature at 140°C, and continue to react for 3 hours, and keep stirring during the reaction. After the reaction, wait for the reaction The kettle was naturally cooled to room temperature, and the reaction suspension was centrifuged to o...

Embodiment 3

[0022] Take 7.7mL of tetrabutyl titanate and slowly add it into 30mL of absolute ethanol while stirring under ultrasonic conditions, and drop the above mixed solution into 50mL of deionized water with a peristaltic pump with a rotation speed of 25rpm. Stir under ultrasonic conditions, and ensure that the temperature of the ultrasonic water bath is 10°C, measure 4mL of CTAB with a concentration of 12g / L and slowly add it dropwise into the prepared tetrabutyl titanate solution, and finally mix the above mixed solution with deionized water Dilute to 100mL and continue to sonicate for 10min. Take 25mL of the prepared precursor mixture and put it into the reactor. Under the condition of energy input of 50W in the ring microwave field, keep the temperature at 140°C, and continue to react for 3 hours, and keep stirring during the reaction. After the reaction, wait for the reaction The kettle was naturally cooled to room temperature, and the reaction suspension was centrifuged to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com